Reduction treatment method applied to high-salt-content wastewater of thermal power plant

A treatment method and high-salt technology, which is applied in water/sewage treatment, chemical instruments and methods, heating water/sewage treatment, etc., can solve the problem of high-salt wastewater treatment in thermal power plants that needs to be improved, easy scaling of equipment, and energy consumption advanced questions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

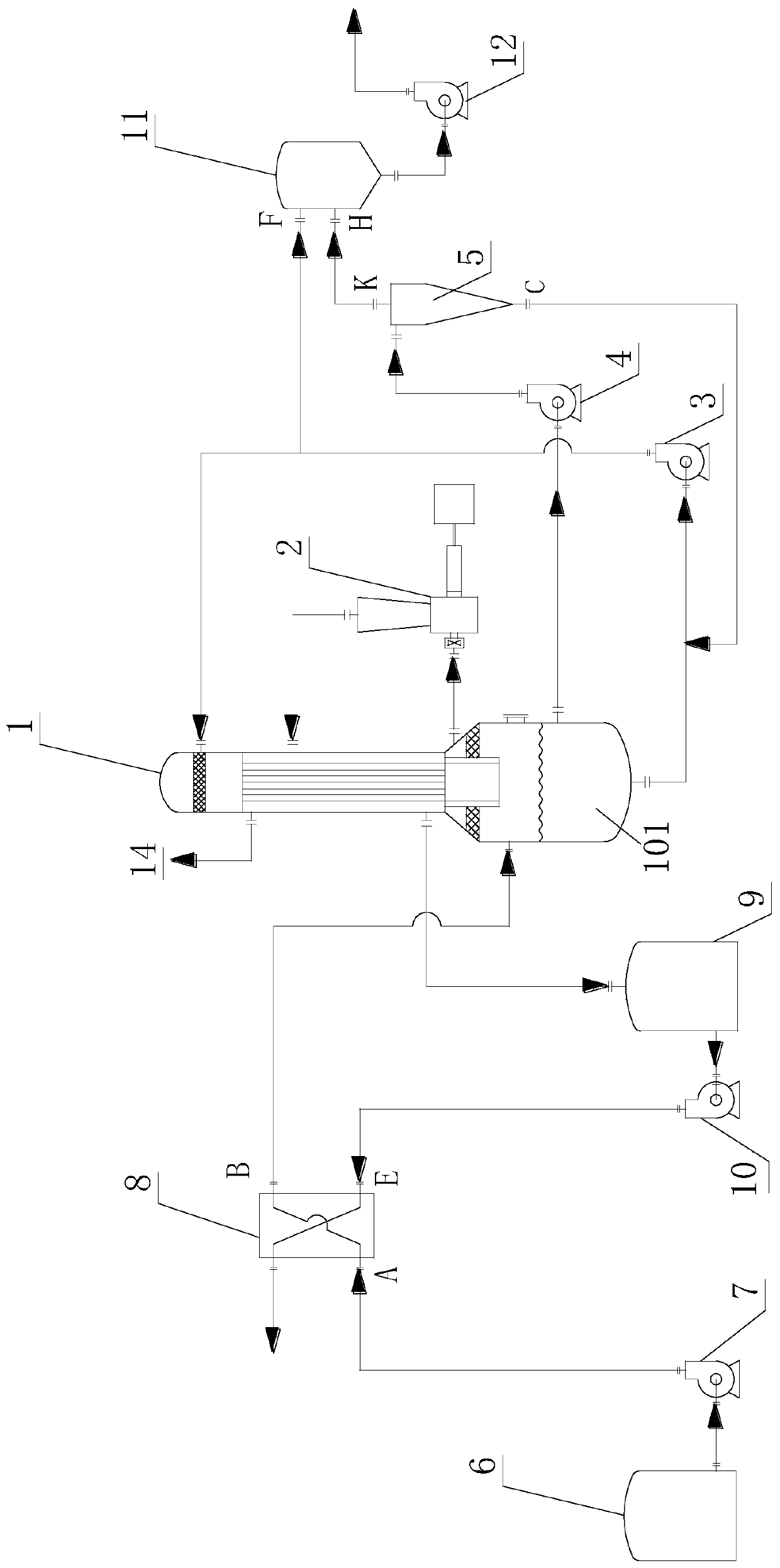

[0026] Below, the present invention will be further described in conjunction with the accompanying drawings and specific implementation methods. It should be noted that, under the premise of not conflicting, the various embodiments described below or the technical features can be combined arbitrarily to form new embodiments. .

[0027] A system for reducing the amount of high-salt wastewater used in thermal power plants, including a stock solution tank 6, a preheater 8, an evaporator 1, a steam compressor 2, and a hydrocyclone 5. The liquid outlet of the raw liquid tank 6 is connected to the first liquid inlet of the preheater 8 (at A in the figure), and the first liquid outlet of the preheater 8 (at B in the figure) is connected to the bottom liquid chamber of the evaporator 1 101 connections. The liquid stored in the bottom liquid chamber 101 is pumped to the tube side of the evaporator 1 by the circulating pump 3 . The inlet end and the outlet end of the vapor compressor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com