Lens barrel and image pickup device

A lens and lens barrel technology, which is applied in the field of fixed optical components, can solve the problems of impact sound, impact transmission to hands, and obvious garbage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

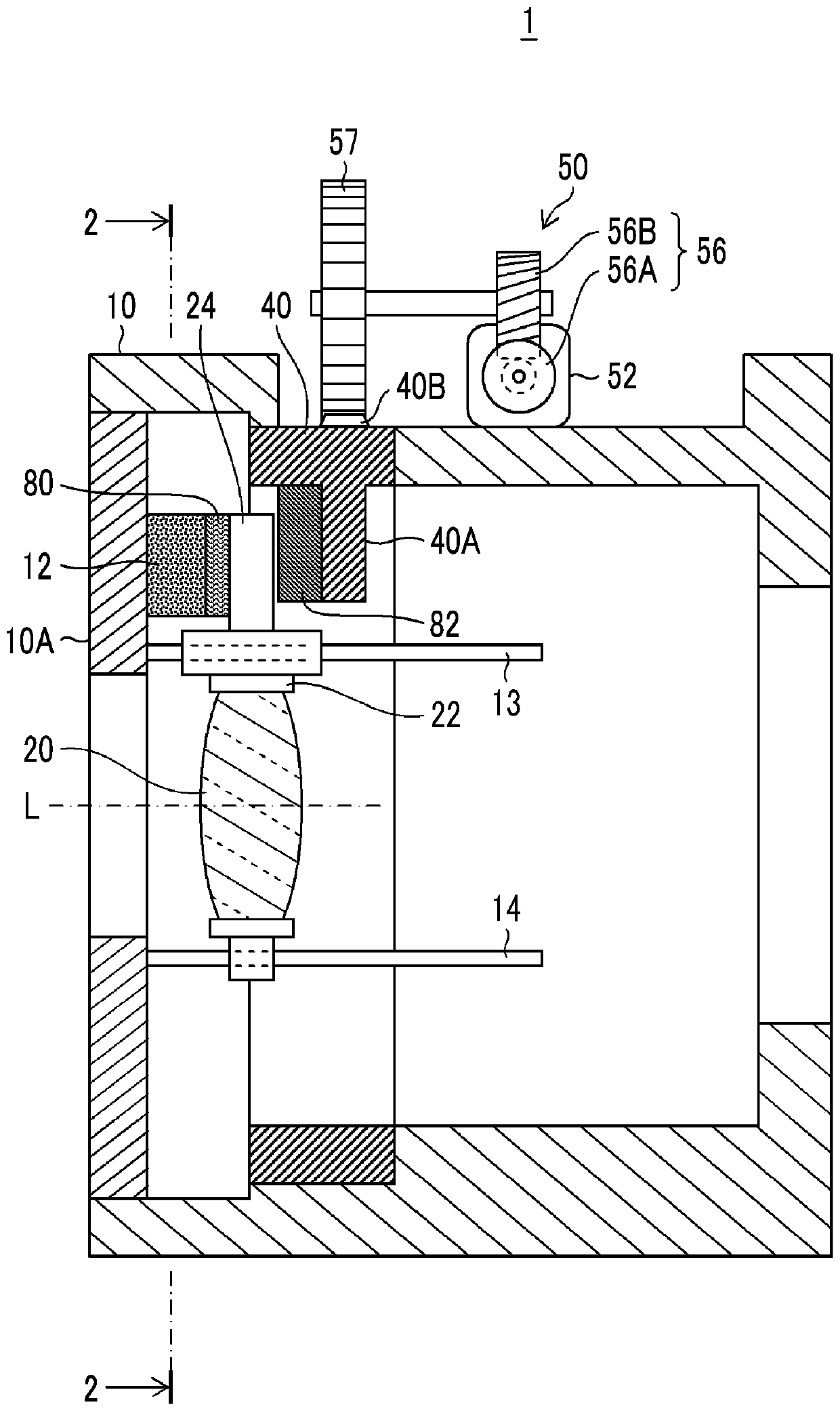

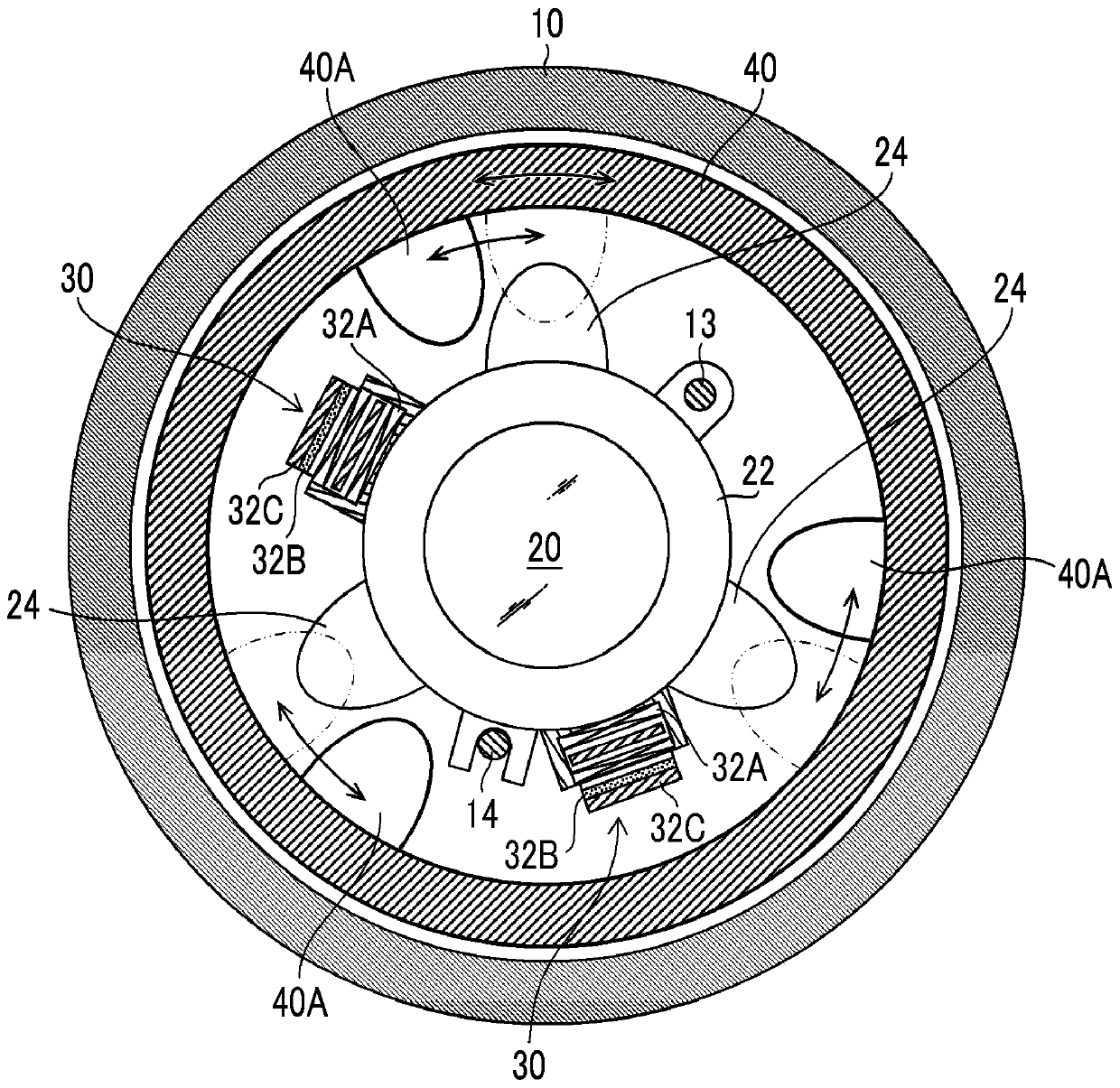

[0081] figure 1 It is a sectional view of the main part showing the first embodiment of the lens barrel according to the present invention, figure 2 is along figure 1 Cutaway view of line 2-2 shown.

[0082] In this example, figure 1 and figure 2 The illustrated lens barrel 1 functions as a fixed focus interchangeable lens of an interchangeable lens camera having an auto focus (Auto Focus / AF) function.

[0083] The lens barrel 1 is mainly composed of a fixed frame 10 , a movable frame 22 that holds an optical component (focusing lens) 20 , a voice coil motor (VCM: Voice Coil Motor) 30 , which is a type of linear motor that drives the movable frame 22 , and limited Movement restriction portion 12 of movable frame 22 , engagement portion 24 provided in movable frame 22 , lock ring 40 functioning as a locking member for fixing (locking) movement of movable frame 22 , and movement of lock ring 40 A (rotating) electric actuator 50 is constituted.

[0084] The main shaft 13 ...

no. 2 Embodiment approach

[0135] Figure 5 It is a perspective view showing a second embodiment of the lens barrel according to the present invention. In addition, with figure 1 and figure 2 The parts common to the lens barrel 1 of the first embodiment shown are denoted by the same reference numerals, and detailed descriptions thereof will be omitted.

[0136] Figure 5 The lens barrel 1 - 2 of the second embodiment shown is different from the first embodiment in that a locking member 40 - 2 is mainly used instead of the lock ring 40 and an abutment member 70 is added.

[0137] Like the lock ring 40 , the locking member 40 - 2 is rotatably supported with respect to the fixed frame 10 about the optical axis L of the focus lens 20 , but is not formed in a ring shape but in an arc shape.

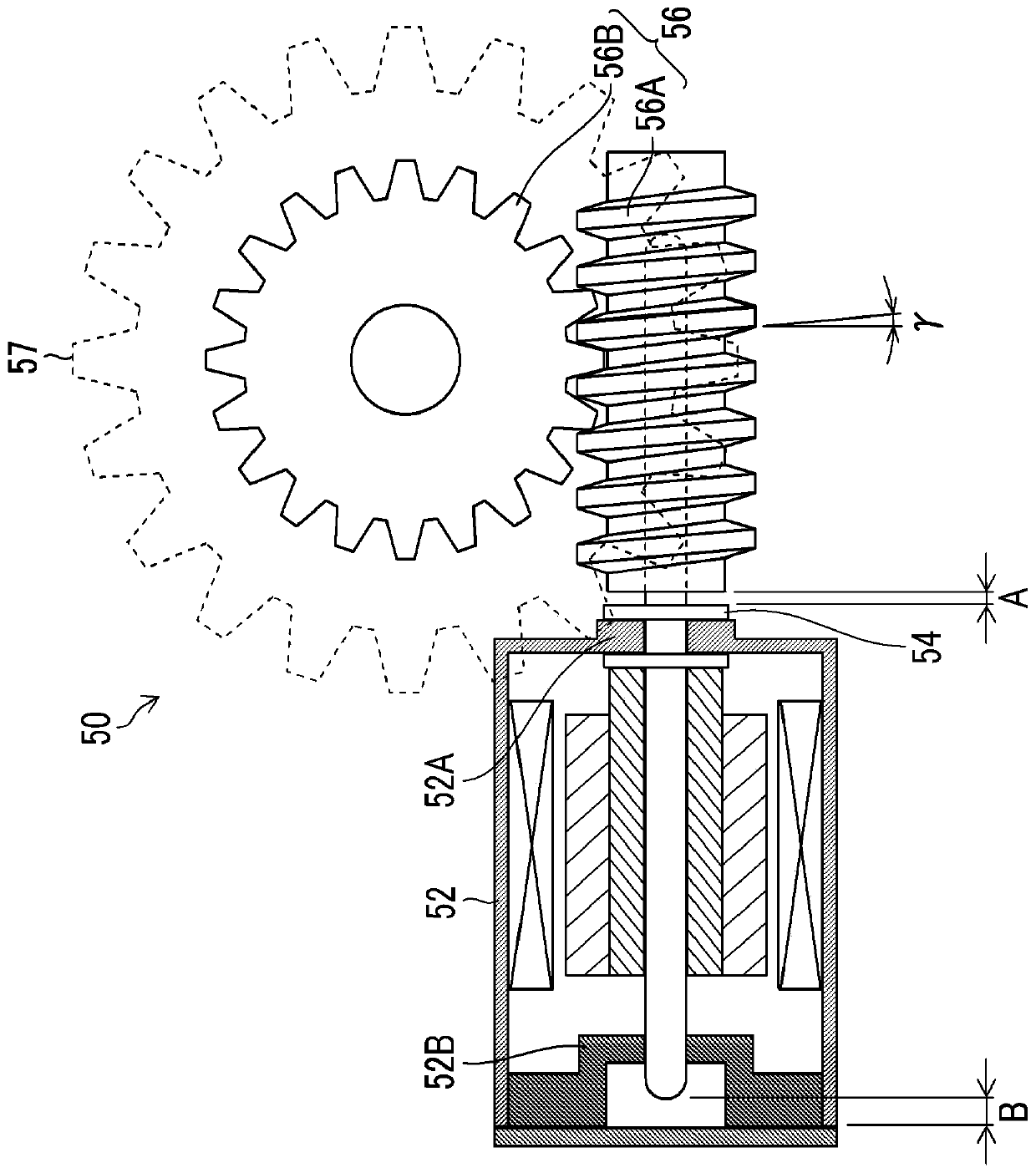

[0138] Image 6 It is a perspective view of the electric actuator 50 applied to the lens barrel 1-2 of the second embodiment.

[0139] Image 6 The spur gear 57 of the gear train of the electric actuator 50 show...

no. 3 Embodiment approach

[0148] Figure 9 and Figure 10 are perspective views each showing a third embodiment of the lens barrel according to the present invention, Figure 9 shows about the unlocked state, Figure 10 The lock state is shown. In addition, the same code|symbol is attached|subjected to the part common to the lens barrel of 1st Embodiment and 2nd Embodiment, and the detailed description is abbreviate|omitted.

[0149] Figure 9 and Figure 10 The main locking member 40-3 of the lens barrel 1-3 of the illustrated third embodiment is different from the locking member 40-2 of the lens barrel 1-2 of the second embodiment.

[0150] like Figure 9 and Figure 10As shown, the locking member 40 - 3 of the lens barrel 1 - 3 of the third embodiment is rotatably supported around a rotation axis parallel to an optical axis different from the optical axis of the optical member (focus lens 20 ).

[0151] The locking member 40 - 3 is locked by the rotational driving force applied from the elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com