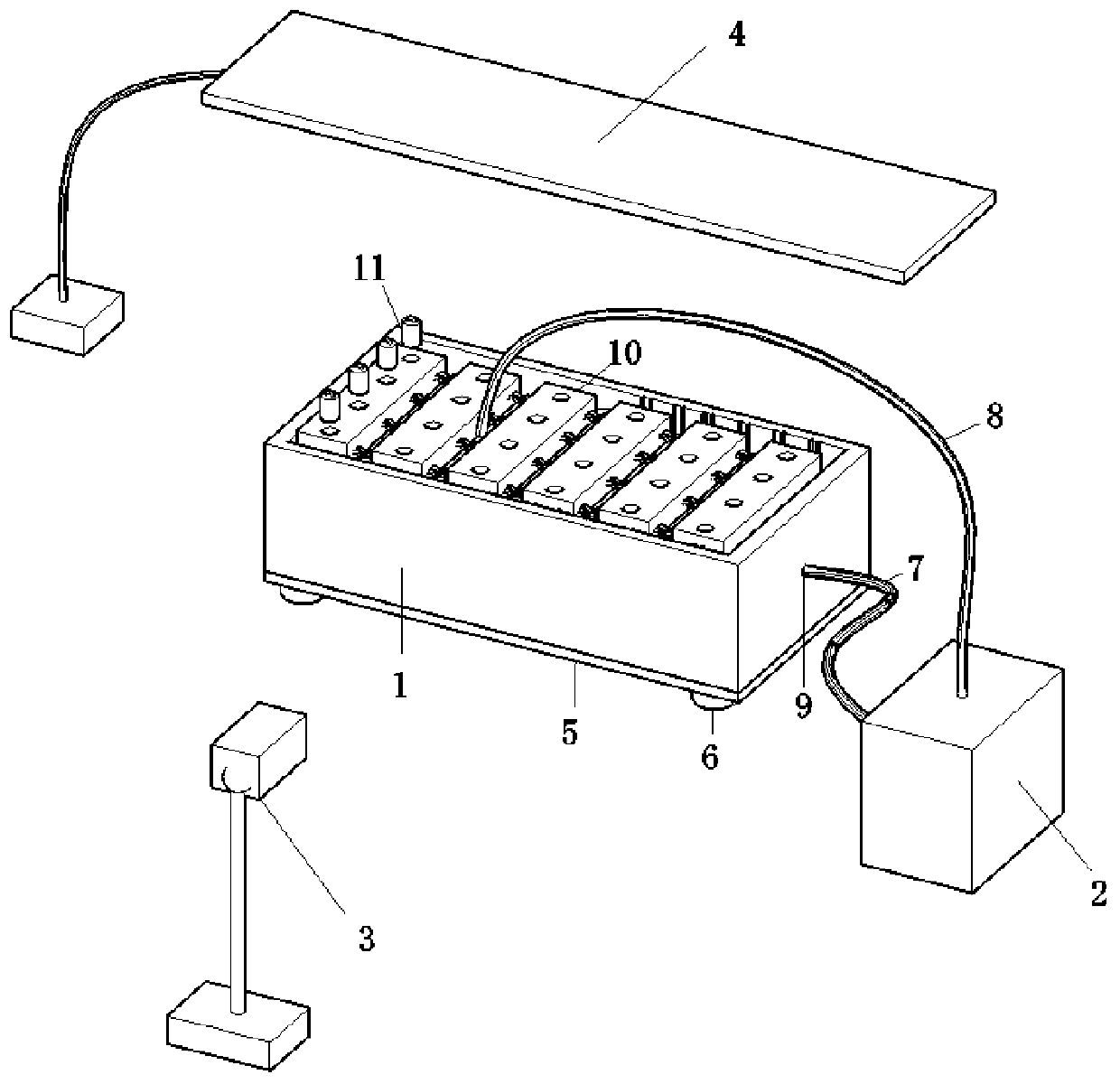

Test device and method for simulating three-dimensional flow state of caving zone filling slurry

A test device and caving zone technology, applied to measuring devices, instruments, scientific instruments, etc., can solve problems such as polluting water bodies, prone to spontaneous combustion, and occupying land resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0040] A mine in Shenmu, Northern Shaanxi mainly mines the 2# coal seam, with a buried depth of 150-200m, a dipping length of the working face of 200m, a dipping angle of the coal seam of 9°, and a caving zone height of 15.3-19.5m, with an average of 17.4m. The filling process of the working face is to carry out high-level and adjacent-level grouting filling in the goaf of the lagging working face, and the filling flow rate is 120m 3 / h.

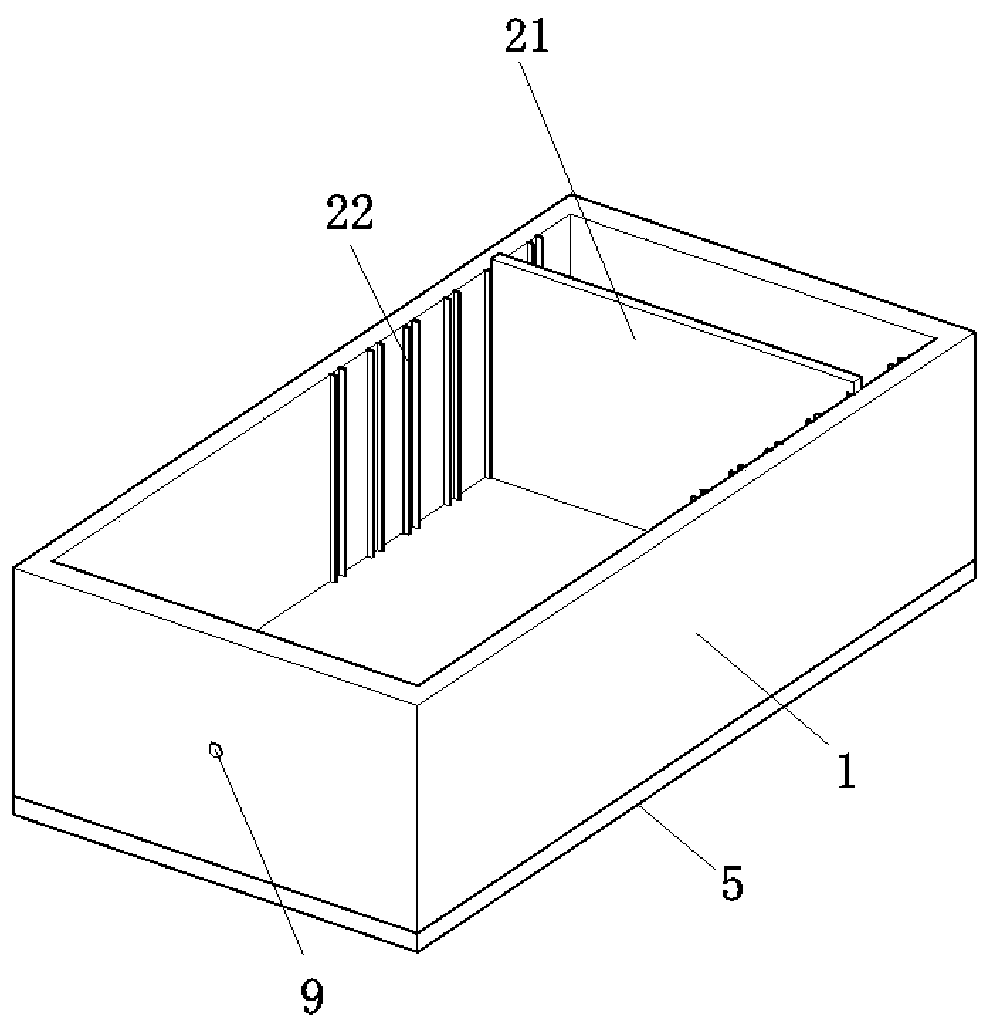

[0041] 1) Determine that the model similarity ratio is 1:100, then the effective length of the slurry diffusion test box is 2000mm, and the baffle plate 22 may not be installed. According to the similarity ratio, the effective collapse zone height is determined to be 180mm, and the flow rate at the end of the filling pipe is controlled at 0.0012m 3 / h, the inclination angle of the coal seam is 9°;

[0042]2) Adjust the manual angle platform 6 of the bottom plate of the box so that the slurry diffusion test box 1 forms a 9° inclination with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com