Building method of novel gob-side packing body

A filling body, a new type of technology, applied in the direction of filling, earthwork drilling, safety devices, etc., can solve problems such as difficult to fully connect the roof, cannot realize active support, and gas exceeds the limit, and achieve the effect of avoiding volume reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in more detail below with reference to schematic diagrams, wherein preferred embodiments of the present invention are shown, and it should be understood that those skilled in the art can modify the present invention described herein while still achieving the advantageous effects of the present invention. Therefore, the following description should be understood as the broad knowledge of those skilled in the art, but not as a limitation of the present invention.

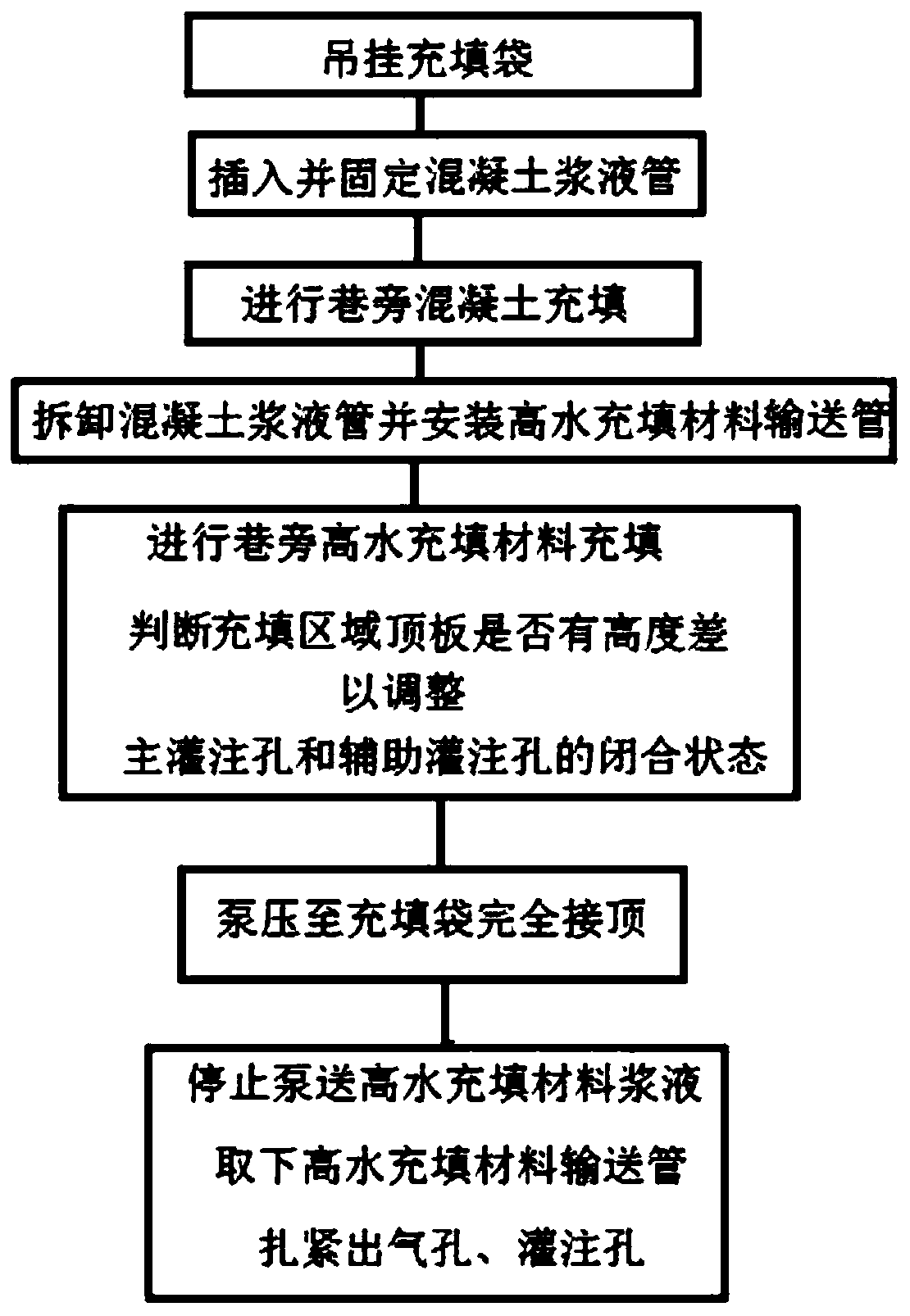

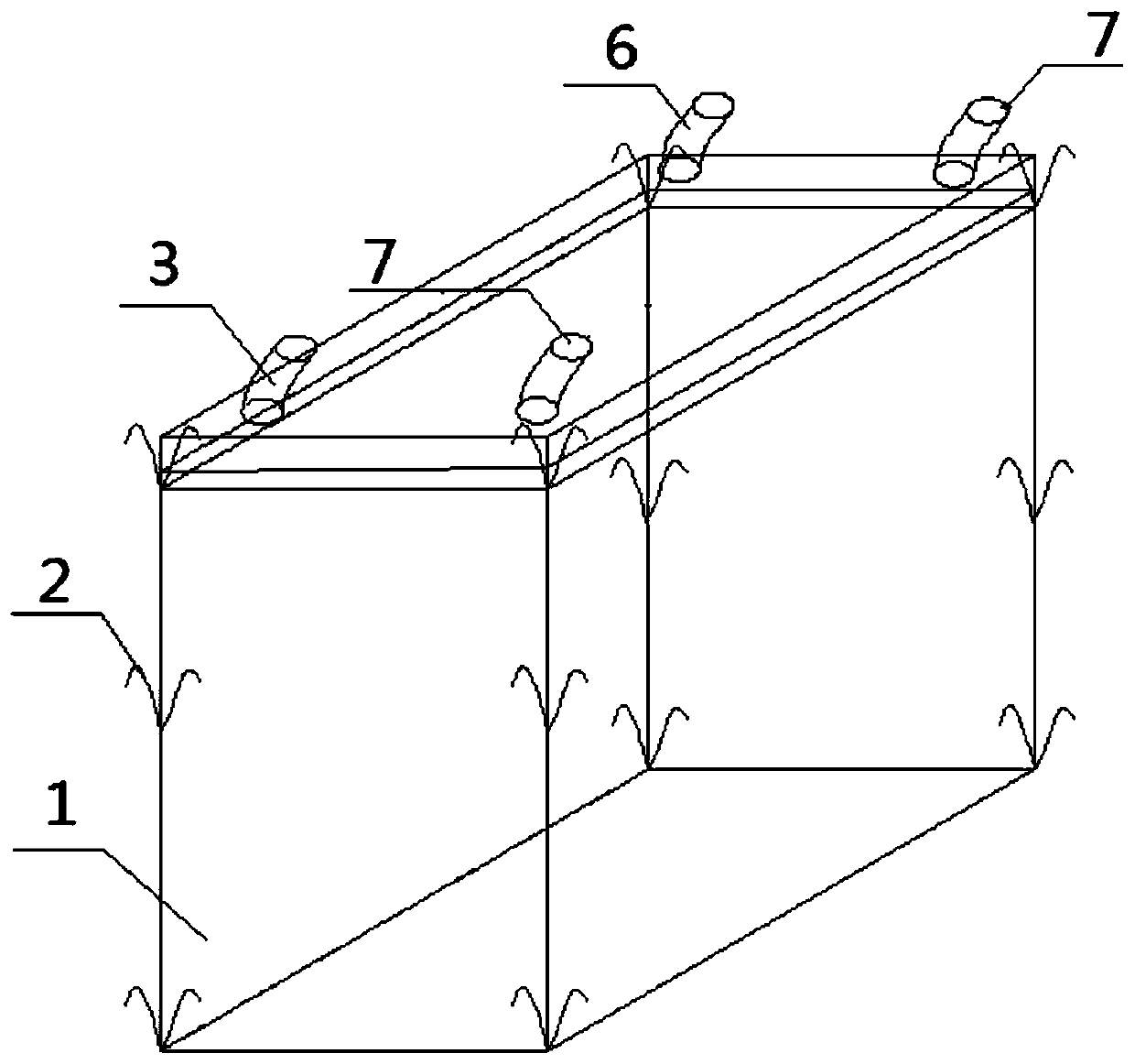

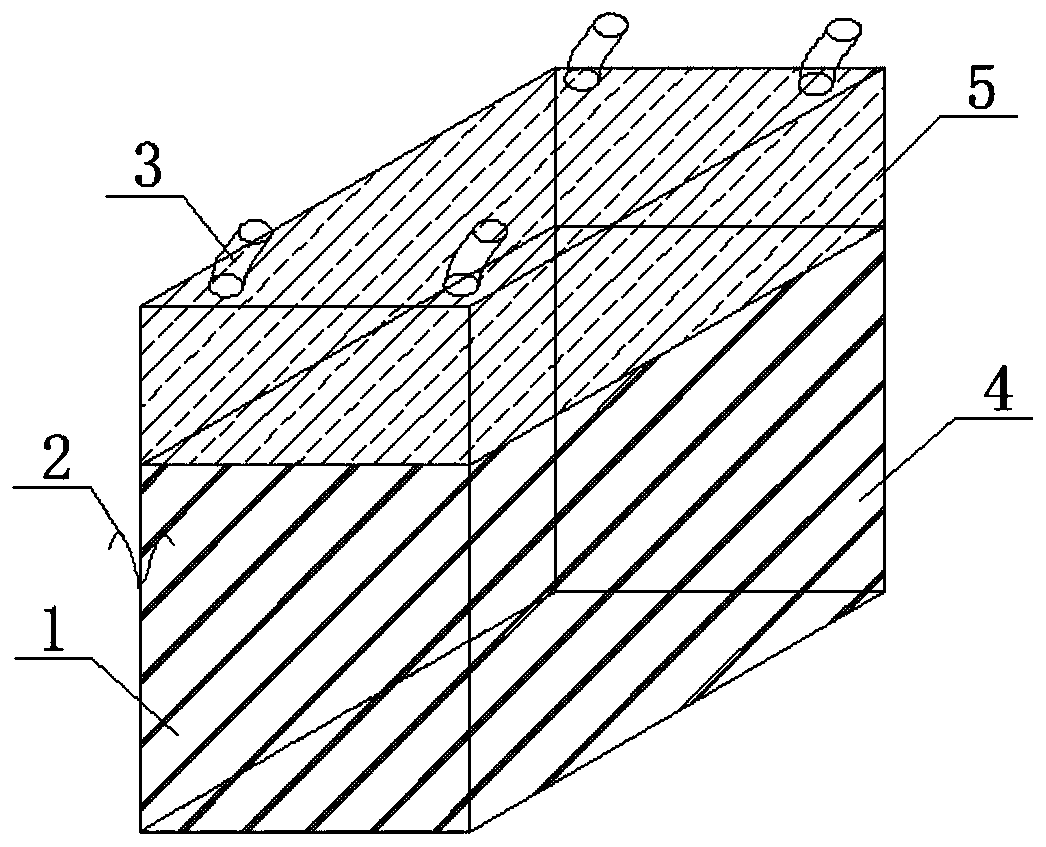

[0027] like figure 1 As shown, a new roadside filling body construction method includes the following steps (1) to (7) to form a filling body with good roofing effect and less prone to deformation and damage. The filling body includes the filling bag 1 and the combined coagulation body in the filling bag 1, and the combined coagulation body includes the concrete coagulation body 4 at the lower part and the high-water filling material coagulation body 5 at the upper part. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com