A drill support device for drilling from bottom to top

A support device and drill bit technology, which is applied in earthwork drilling, shaft equipment, reverse sinking, etc., can solve problems such as inconvenient manual operation, mechanical instability caused by force, and reduced service life, so as to improve force instability problems, improved safety, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

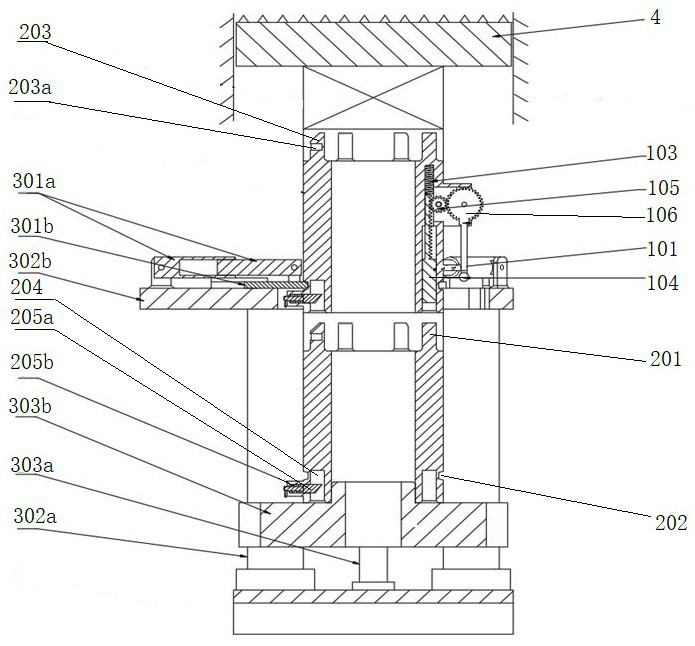

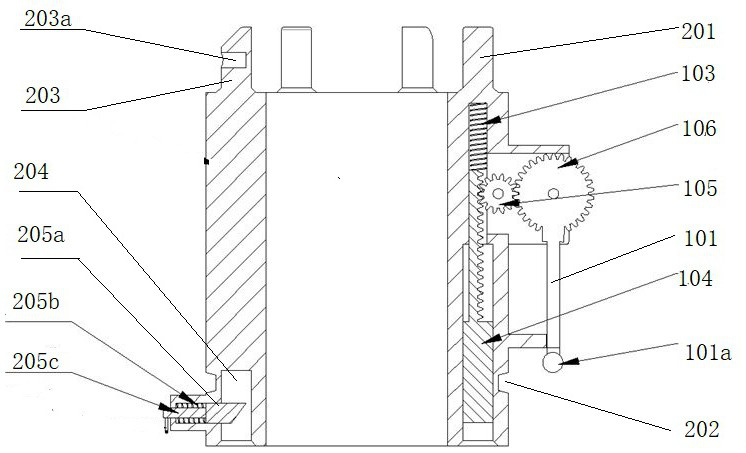

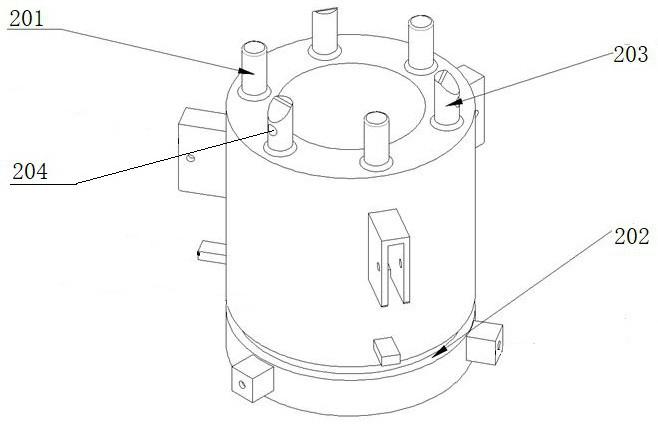

[0047] Such as figure 1 , the present invention proposes a drill support device for drilling from bottom to top, including a lifting platform module and a plurality of support cylinders.

[0048] Such as Figure 7 , the lifting platform module includes a lift base, a plurality of vertical support columns 302a and a support platform 302b fixed above the support columns 302a; the support platform 302b is located above the lift base. Several support connection male heads are arranged on the support platform 302b. The support connection male head includes a horizontal hydraulic cylinder 301a and a support pin 301b; one end of the horizontal hydraulic cylinder 301a is fixed, and the other end is connected to the support pin 301b.

[0049] Such as Figure 8, the lifting base includes a lifting hydraulic cylinder 303a and a supporting plate 303b for placing the support cylinder; the lifting hydraulic oil cylinder 303a drives the supporting plate 303b up and down; the supporting pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com