Steel reinforcement connecting device

A connecting device and steel bar technology, which is applied in the direction of structural elements, building components, building reinforcements, etc., can solve problems such as the inability to realize the overall connection of steel bar parts, the difficulty of ensuring the quality of steel bar connections, and the inability to realize steel bar connections, etc., to ensure the quality of building structures , fast construction speed and simplified construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with drawings and embodiments.

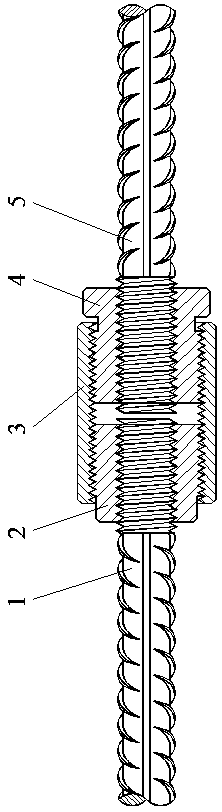

[0029] see Figure 1 to Figure 6 , the casing self-locking steel bar connection device according to the embodiment of the present invention, which includes the connected steel bars 1, 5, through the self-locking sleeve 2, the positioning self-locking sleeve 4 and the sleeve 3.

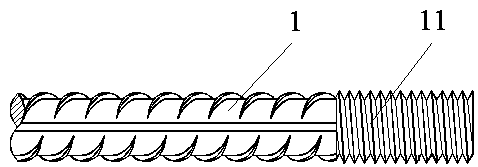

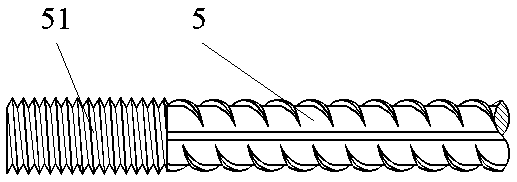

[0030] One of the two connected steel bars is a steel bar 1 with a short external thread 11 at the end, and the other is a steel bar 5 with a long external thread 51 at the end.

[0031] The material of the self-locking sleeve 2 is high-quality carbon steel, and the self-locking sleeve is provided with an internal thread 22 that matches the external thread 11 on the connected steel bar 1. The screwing of the internal and external threads will pass through the self-locking The sleeve 2 is installed on the steel bar 1 to be connected, and the self-locking sleeve 2 is also provided with an externa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com