Installation and construction method of a self-locking lock and a few-shaped steel bar

A construction method and a zigzag technology, which are applied in the processing of building materials, construction, building structure, etc., can solve the problems of abnormal use of production line equipment, difficulty in setting up and dismantling safety guardrails, and difficulty in installing and positioning special-shaped components. The effect of setting up demolition is simple and easy, reducing the consumption of manpower and time, and simplifying the cumbersome construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

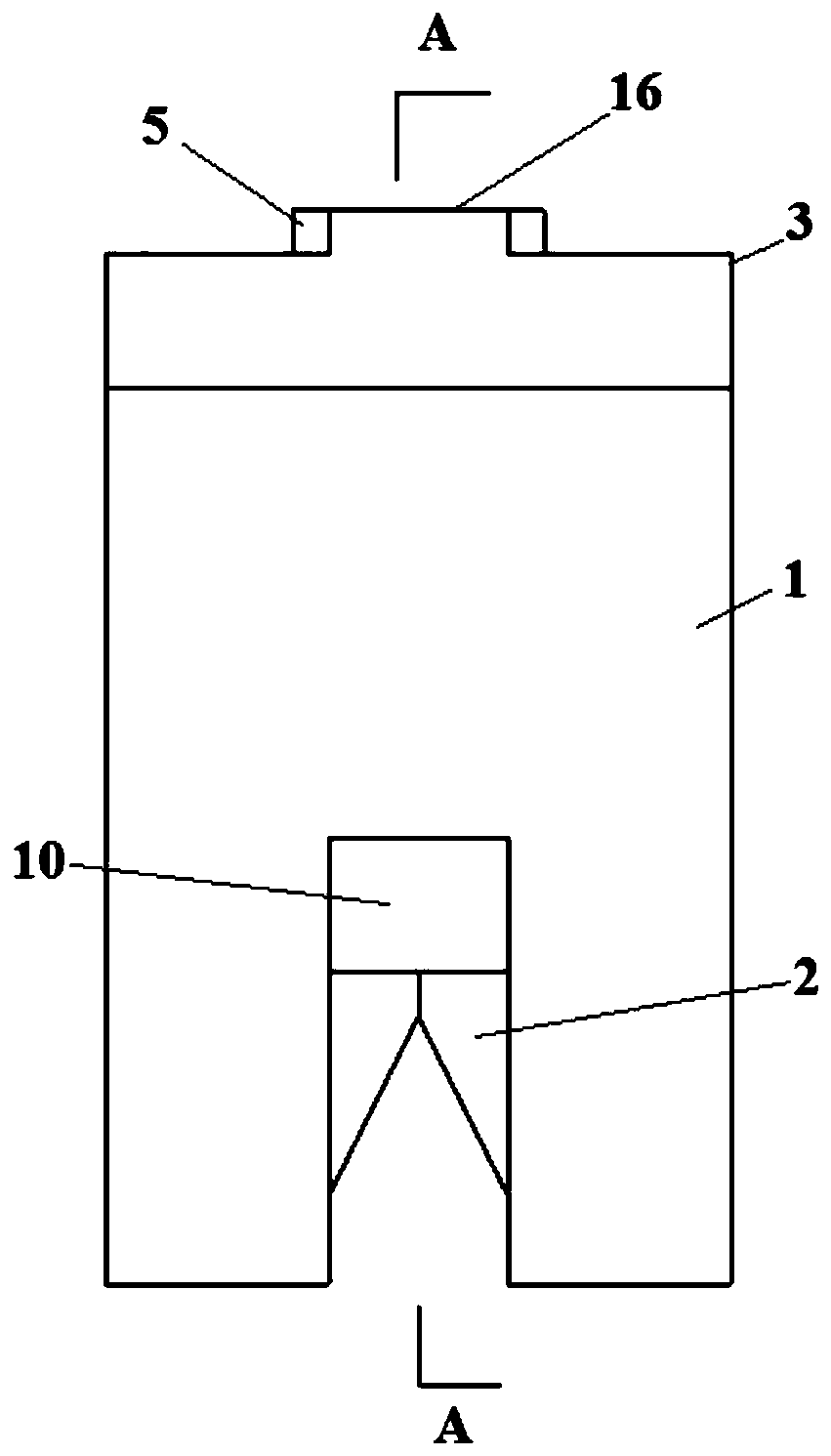

[0073] This embodiment provides a kind of self-locking lockset, such as Figure 1 to Figure 16 As shown, it includes a lock cylinder 1 and a lock tongue 2, and also includes a twist cover 3. A mounting hole 4 is processed in the center of the twist cover 3. A connecting post 5 is arranged at the center of the top of the lock cylinder 1, and the connecting post 5 is installed in the mounting hole. 4, the twist cover 3 can be rotated with the connecting column 5 as the center of rotation, a pair of connecting clips 6 are provided at the bottom of the twist cover 3, and a connecting slot 7 corresponding to the connecting clip 6 is provided at the top of the lock cylinder 1. The connecting card slot 7 is provided with the same diameter around the central axis of the lock cylinder 1, and the connecting card head 6 cooperates with the connecting card slot 7 to achieve a locked connection between the twist cover 3 and the lock cylinder 1 in the axial direction;

[0074] The connectin...

Embodiment 2

[0092] This embodiment provides a method of installation and construction of a self-locking lock and a few-shaped steel bar. The self-locking lock in this method adopts the self-locking lock in Example 1. Specifically, as Figure 21 to Figure 23 As shown, the method includes the following steps:

[0093] Step 1, making several-shaped reinforcing bars 21 and several-shaped reinforcing bar hole molds 22, said several-shaped reinforcing bars 21 comprising a pair of vertical reinforcing bars 21-1, a top transverse reinforcing bar 21-2 and a pair of bottom transverse reinforcing bars 21 -3, the tops of a pair of vertical steel bars 21-1 are respectively connected with one end of the top horizontal steel bar 21-2, and the bottom ends of a pair of vertical steel bars 21-1 are respectively connected with one end of a bottom horizontal steel bar 21-3; The horizontal reinforcement 21-2 is parallel to the bottom horizontal reinforcement 21-3, and the angle between the top horizontal reinfo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com