Flame-retardant butyl pressure sensitive adhesive tape

A flame retardant butyl pressure-sensitive tape, tape roll technology, applied in pressure-sensitive films/sheets, adhesives, film/sheet adhesives, etc., can solve the problems of potential safety hazards, flammability, low ignition point, etc. Achieve the effect of reducing work failure, improving stability, improving service life and work quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below in conjunction with the embodiments.

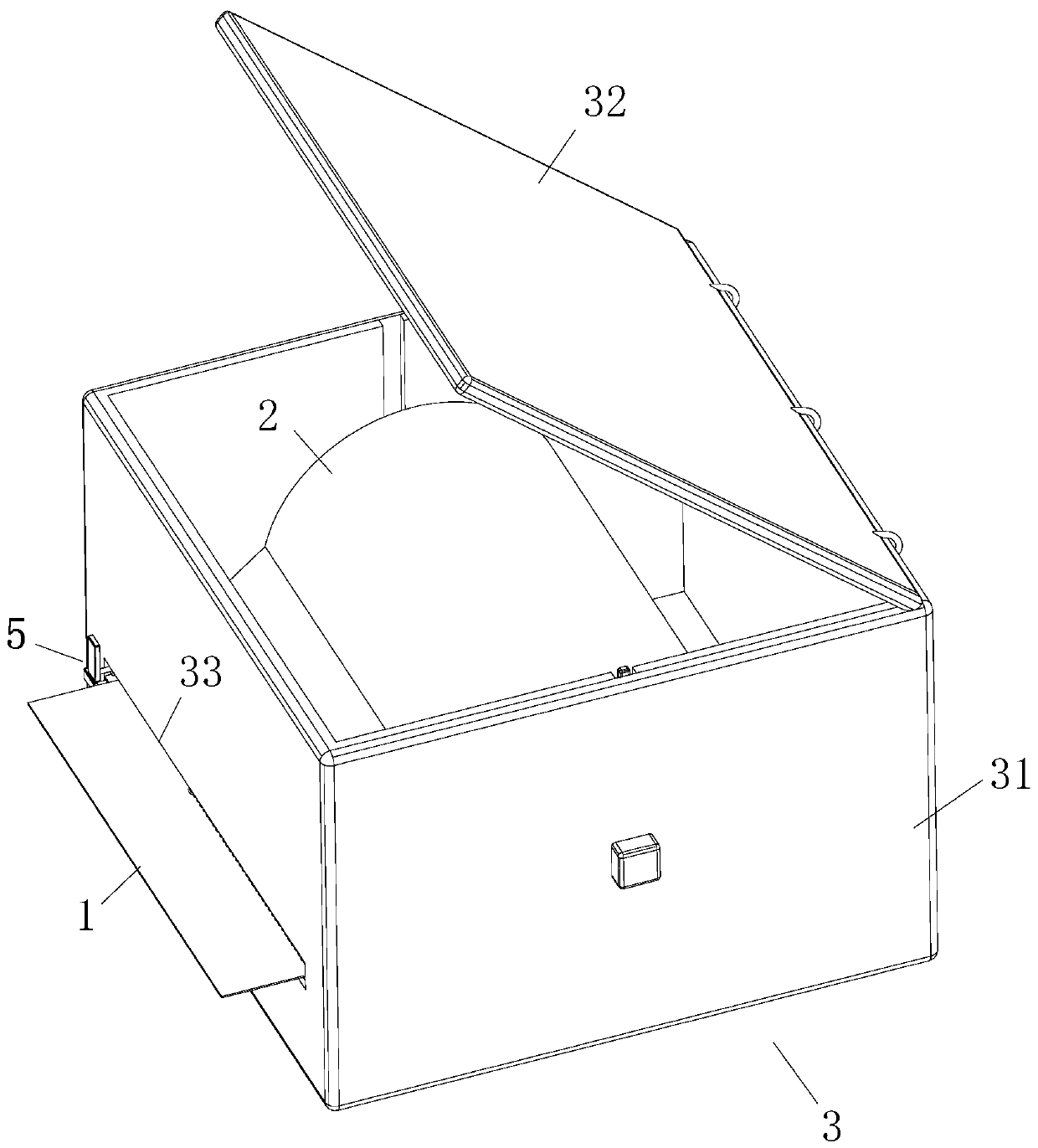

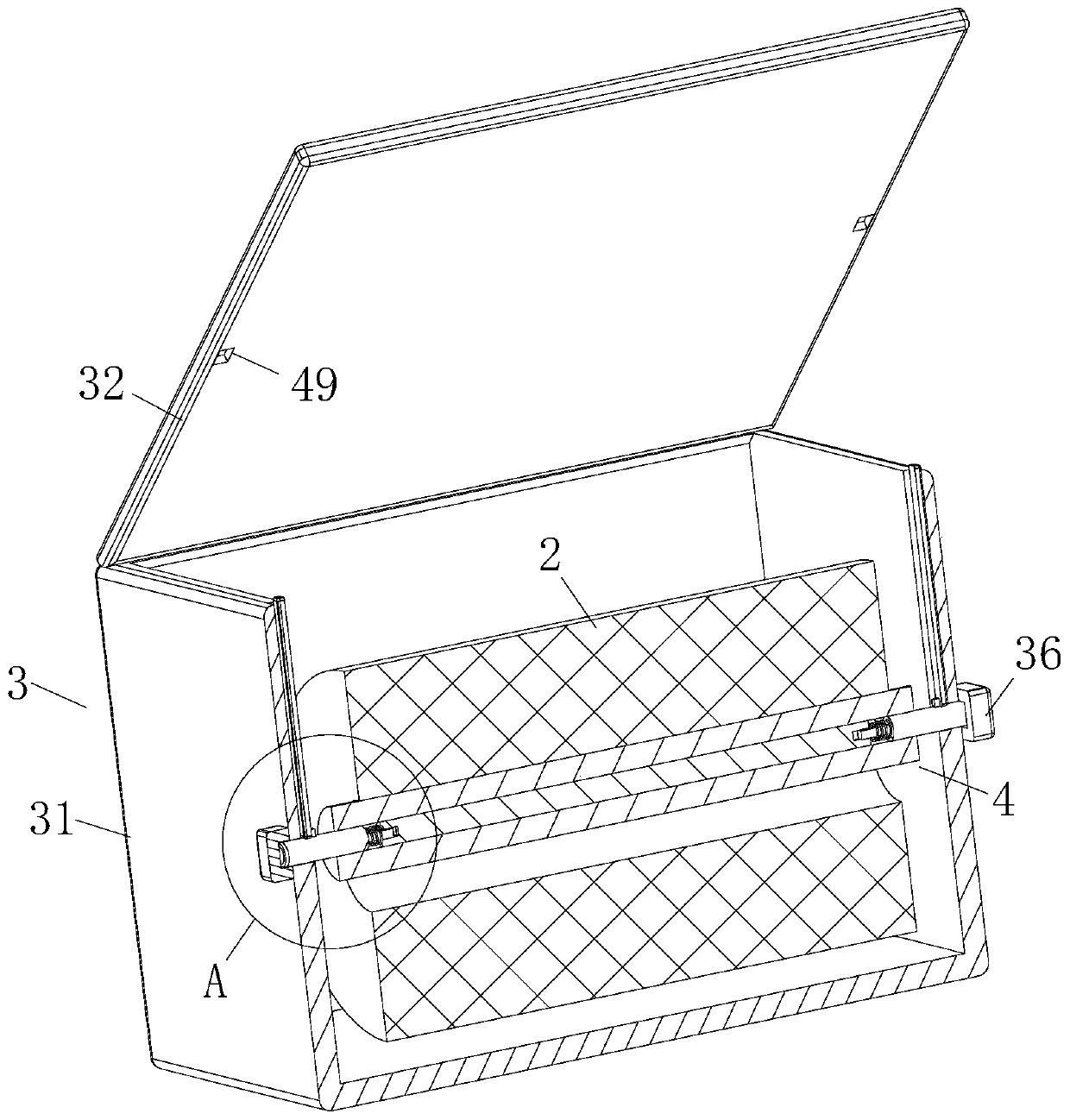

[0023] Such as Figure 1-Figure 5 As shown, a flame-retardant butyl pressure-sensitive adhesive tape according to the present invention includes a body 1 and an annular reel cavity, and the body 1 is wound on the outer surface of the reel cavity to form a tape roll 2; the body 1 A layer of phosphorus-nitrogen flame retardant coating is painted on the non-working surface of the tape roll 2. A protective device 3 that can cooperate with it is provided on the outside of the tape roll 2. The protective device 3 includes a protective cavity 31 and a protective cover 32. The protective cover 32 is rotatably mounted on the top side of the protective cavity 31, the protective cavity 31 is provided with an outlet groove 33 along the side corresponding to the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com