Superfine crushing and discharging device for fungus raw materials

A technology of ultra-fine pulverization and discharging device, which is applied in the direction of grain processing, etc., can solve the problems of inability to achieve consistent ultra-fine pulverization of fungi raw materials, and inability to make full use of fungi raw materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

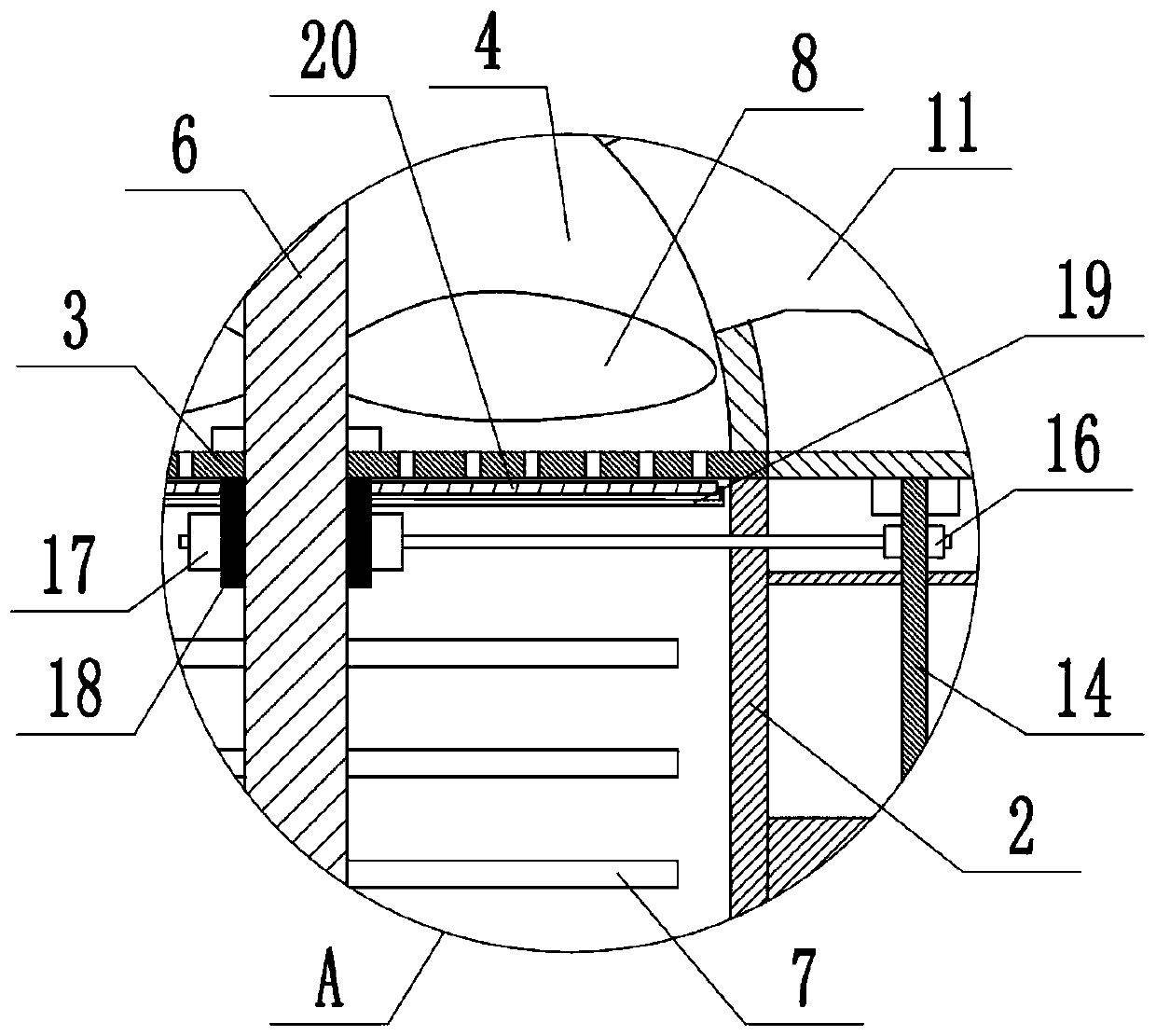

[0038] Embodiment one is basically as attached figure 1Shown: the superfine pulverization and discharging device for fungi raw materials, including a support frame 1 and a crushing cylinder 2 fixedly connected to the support frame 1 by bolts. The left side wall of the crushing cylinder 2 is welded with a feeding hopper, and the crushing cylinder 2 is provided with an opening at the top and a screen 3 is welded on the top of the crushing cylinder 2, and a negative pressure chamber 4 is welded on the top of the screen 3.

[0039] Such as figure 1 As shown, the bottom of the crushing cylinder 2 is provided with a driving mechanism. In this embodiment, the driving mechanism includes a driving motor 5 and a rotating shaft 6 fixedly connected to the driving motor 5 through a flat key. The driving motor 5 is fixedly connected to the support frame 1 through bolts. Above and the drive motor 5 is located below the crushing cylinder 2, the top of the rotating shaft 6 passes through the ...

Embodiment 2

[0047] The difference between embodiment two and embodiment one is: as figure 2 and image 3 As shown, the bottom of the screen 3 is provided with a scraper mechanism for scraping the bottom of the screen 3, and a second transmission member is connected between the scraper mechanism and the driven shaft 14. In this embodiment, the second transmission member includes Drive wheel 16 connected by chain and driven wheel 17, drive wheel 16 is fixedly connected on the driven shaft 14 by flat key, the bottom of screen cloth 3 is connected with rotating cylinder 18 that is coaxially arranged with rotating shaft 6 by bearing rotation, driven wheel 17 is fixedly connected on the rotating drum 18 by a flat key; the scraping mechanism includes a rotating rod 19 welded on the rotating drum 18, and a scraper 20 is welded on the rotating rod 19.

[0048] In this embodiment, when the driven shaft 14 rotates, it will drive the driving wheel 16 to rotate, and the driving wheel 16 will drive t...

Embodiment 3

[0050] The difference between embodiment three and embodiment two is: as Figure 4 As shown, the rotating rod 19 is coaxially connected with a sleeve 21, and the outer wall of the sleeve 21 is welded with thorns 22. The meshes on the screen 3 are radially along the center of the screen 3, and the thickness of the screen 3 is When the rotating rod 19 rotates with the rotating cylinder 18, the sleeve 21 rotates along the bottom surface of the screen 3, and the thorns 22 on the outer wall of the sleeve 21 can be inserted into the mesh of the screen 3, thereby avoiding ultrafine crushing. The final fungus raw materials block the mesh holes to ensure the filtration efficiency of the sieve 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com