A fan blade detection device

A detection device and fan blade technology, applied in the direction of measurement device, electromagnetic measurement device, electric device, etc., can solve the problems of poor balance, increased fan noise, and lack of good detection tools for the fan blade, so as to prevent the factory from leaving the factory and improve the quality of the fan blade. The effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

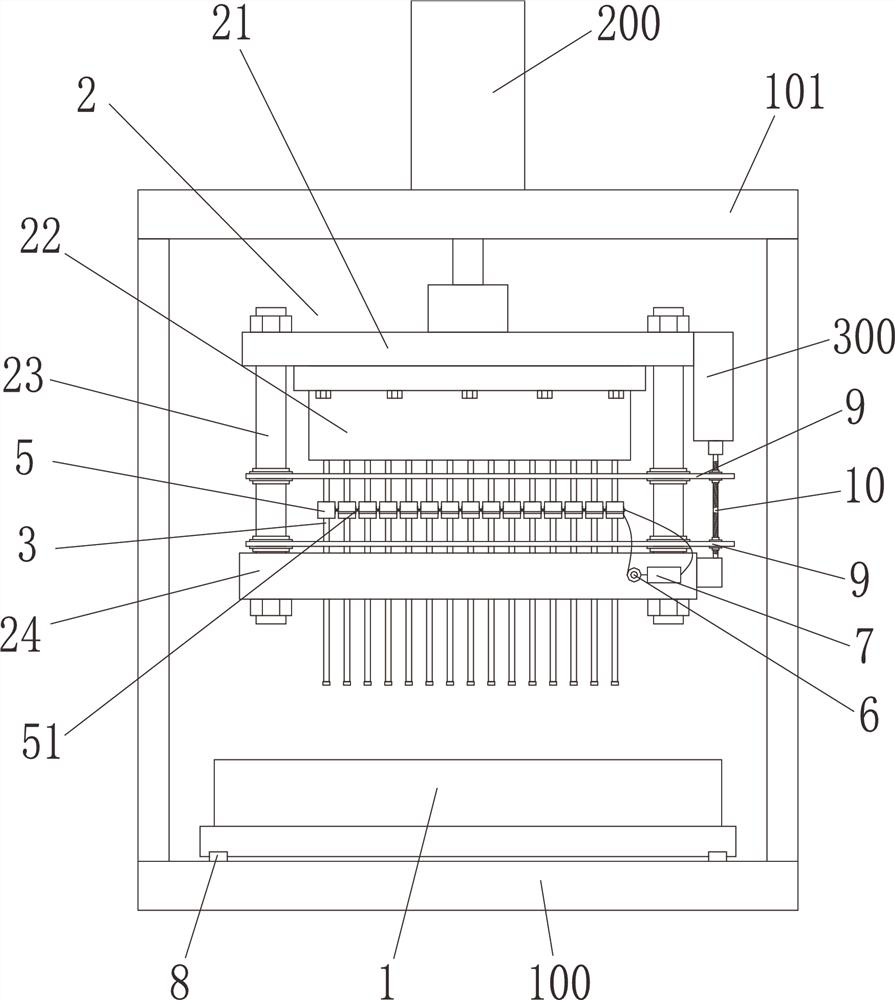

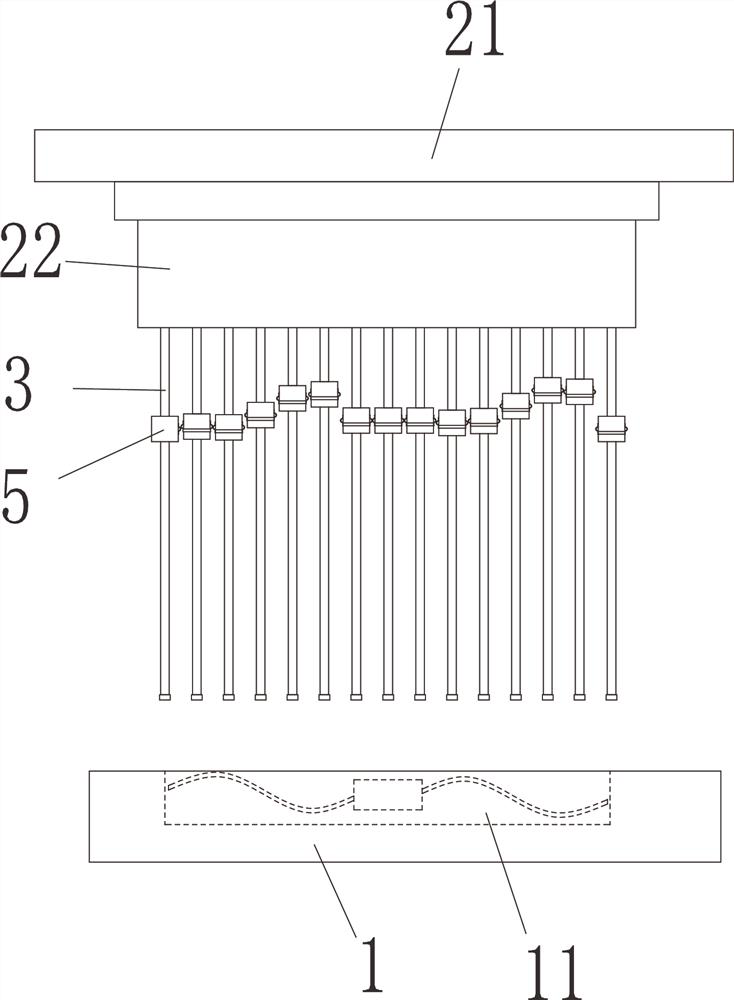

[0023] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment: see Figure 1 to Figure 9 , a fan blade detection device, including a bottom mold 1 and a lifting mold 2, the bottom mold 1 is provided with a positioning groove 11 for positioning the blades, and the bottom mold 1 is arranged on a base 100, specifically, in this embodiment , in order to facilitate the installation of fan blades into the bottom mold 1 , a slide rail 8 is provided between the base 100 and the bottom mold 1 .

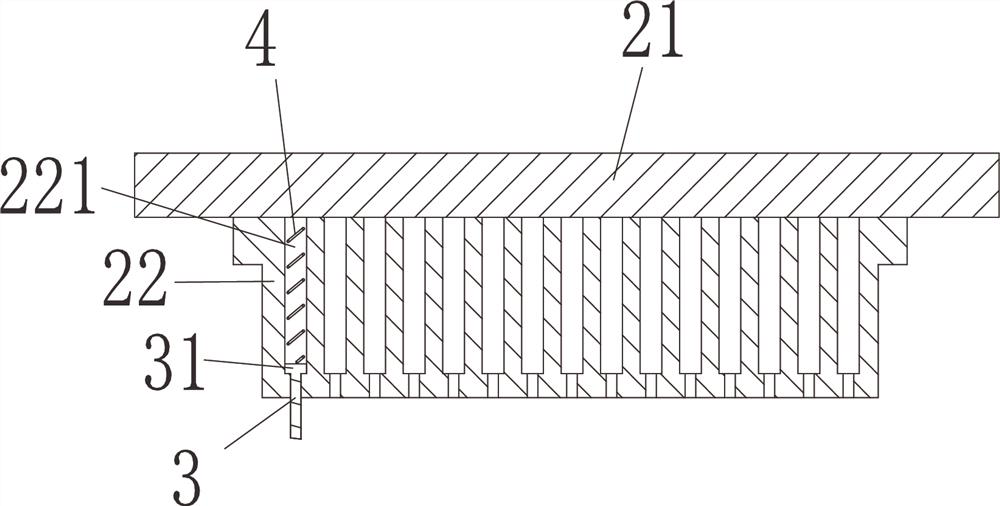

[0024] The bottom of the lifting mold 2 is provided with some liftable ejector pins 3, and the upper ends of several ejector pins 3 are provided with elastic members 4. In this embodiment, the lifting mold 2 includes a top plate 21 and an intermediate housing 22, and the top of the intermediate housing 22 is evenly spaced. A number of mounting grooves 221 are provided, and elastic parts 4 are installed in the mounting gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com