High-temperature gas cooled reactor helium compressor isolation pressure maintaining overhaul method and device

A technology for high-temperature gas-cooled reactors and maintenance devices, which is applied to lifting devices, reduction of greenhouse gases, and reactors. It can solve the problems of long shutdown time, large economic losses, and access to the primary circuit, etc., to reduce shutdown time and facilitate maintenance. , Guarantee the effect of reliability and life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

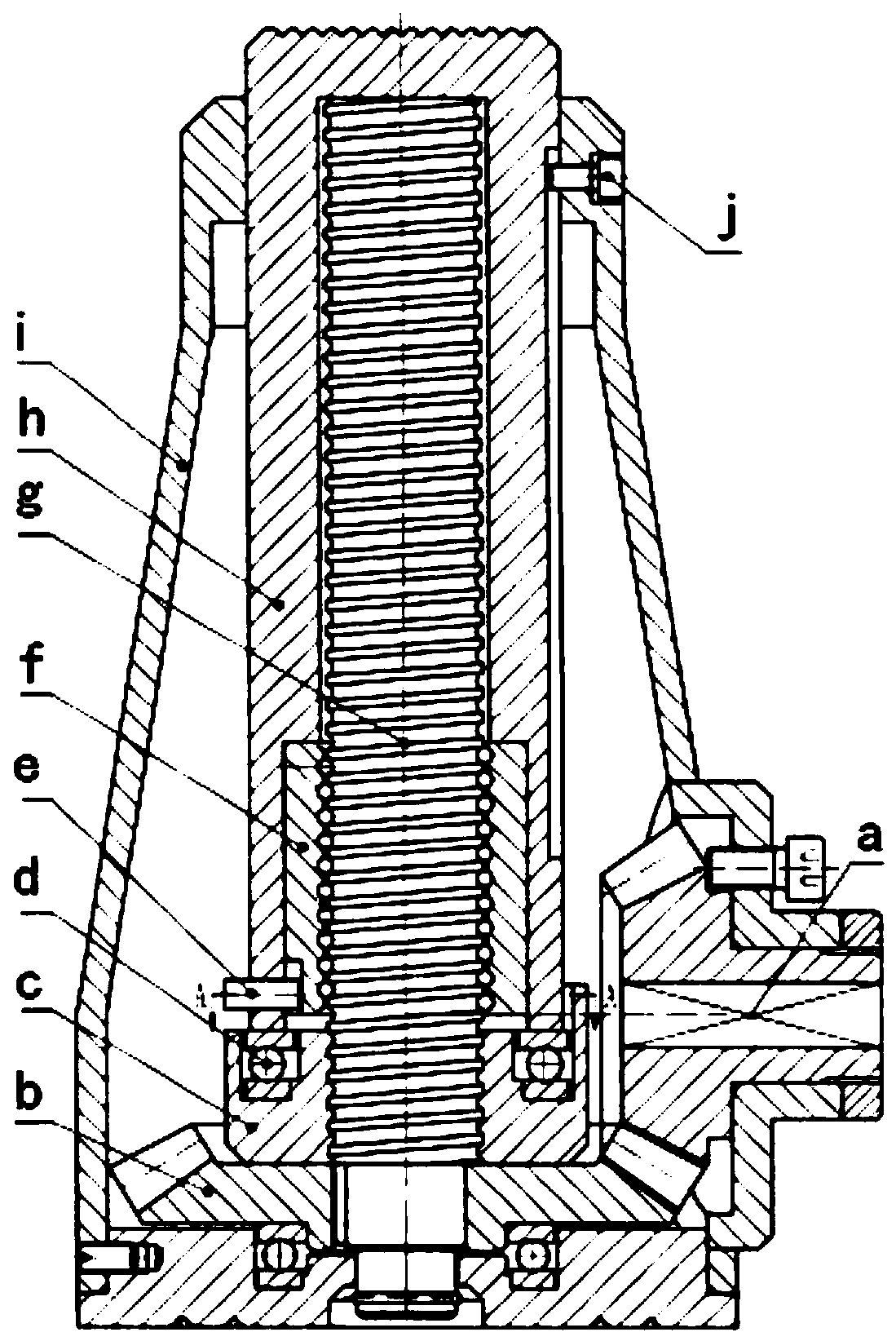

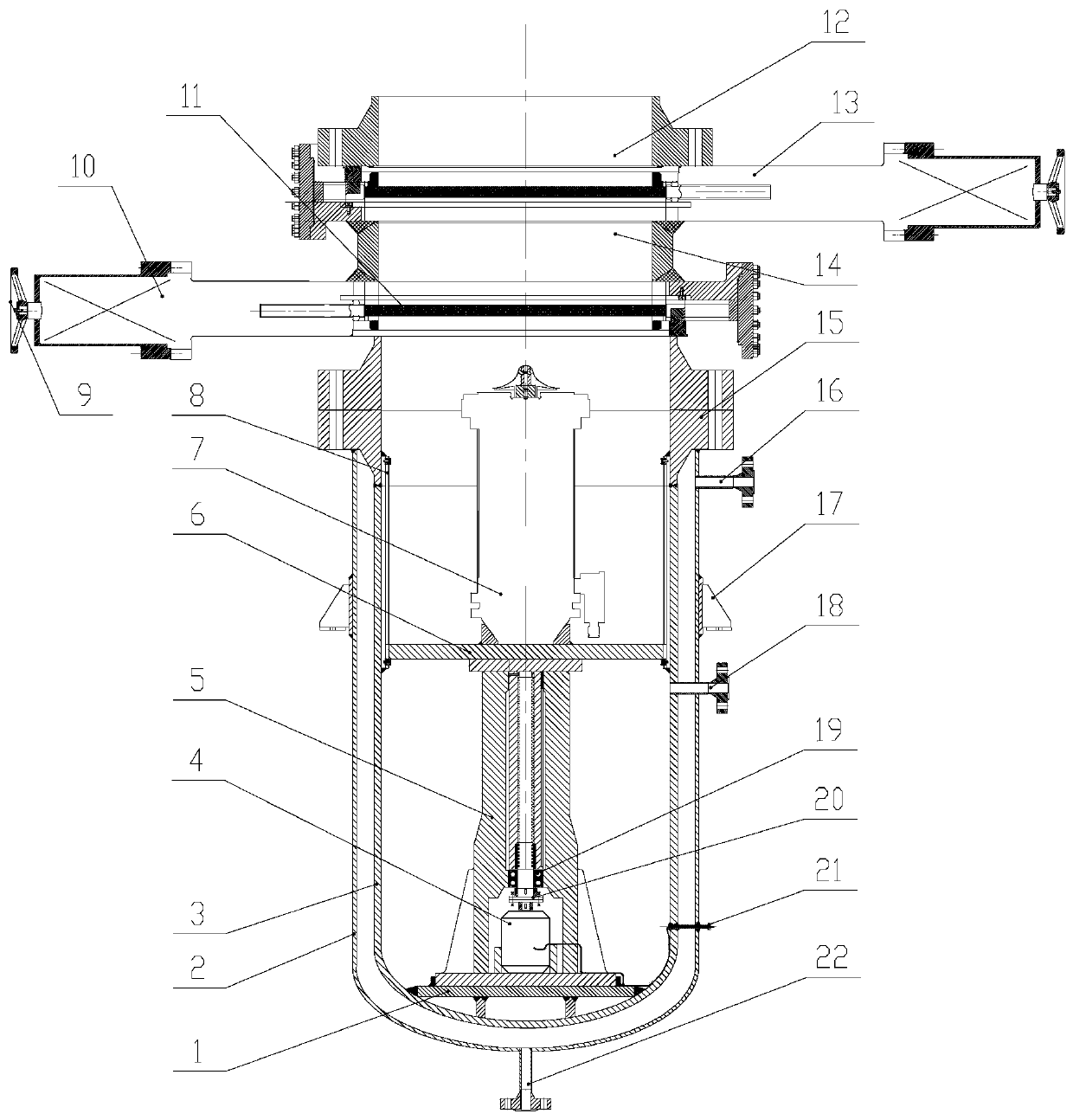

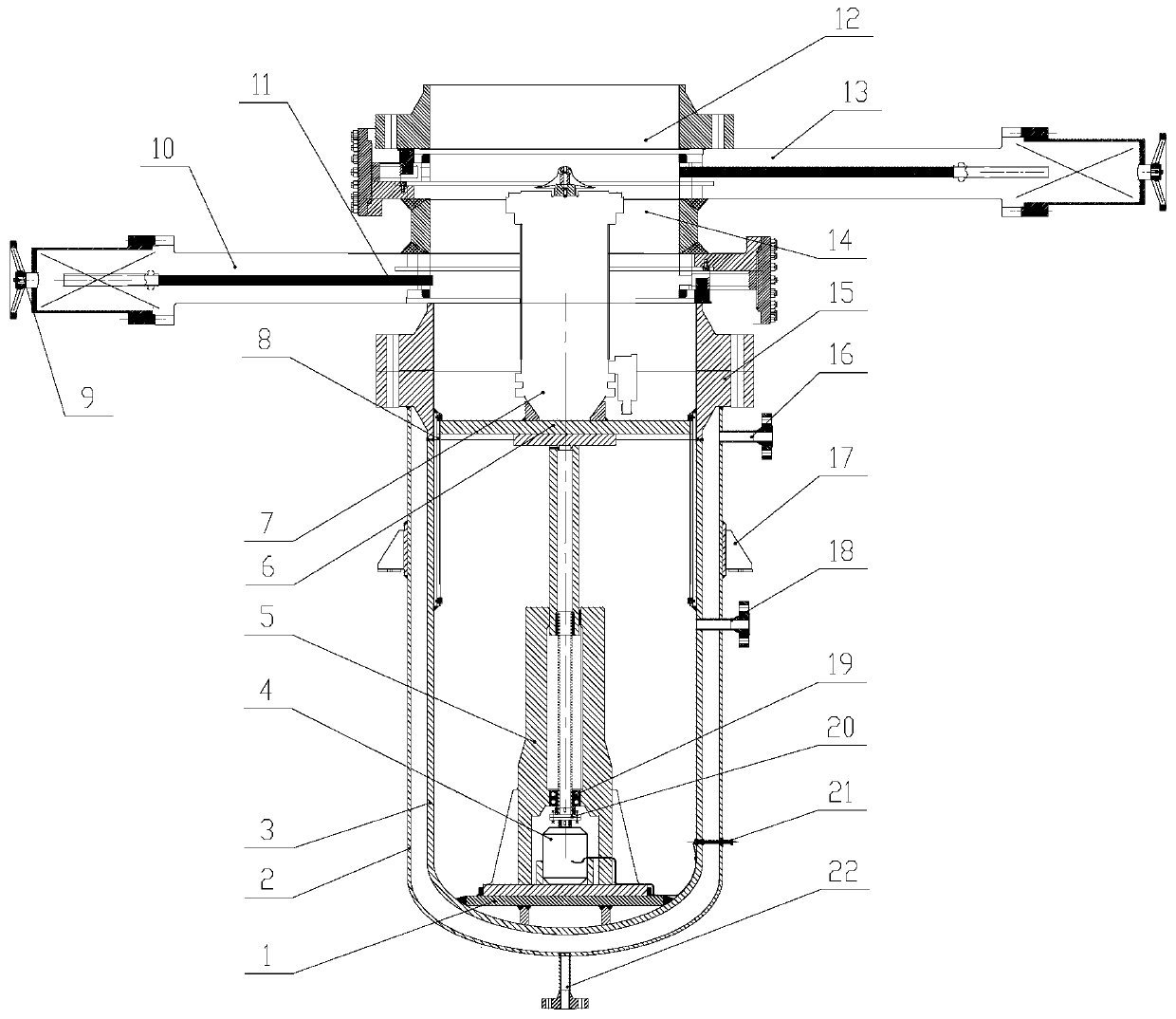

[0031] The high-temperature gas-cooled reactor helium compressor isolation and pressure maintenance maintenance device provided by the present invention has a structure such as figure 2 with image 3 As shown, it includes a screw lifting body, a clamping sleeve body 2, a pressure vessel cylinder 3, an upper support plate 6, a lower support plate 1, an upper maintenance isolation valve 13 and a lower maintenance isolation valve 10, the clamping sleeve body 2 It is sleeved on the outside of the pressure vessel cylinder 3, the clamping sleeve body 2 is provided with a cooling water inlet 22 and a cooling water outlet 16, the pressure vessel cylinder 3 is provided with a vacuum port 18, and the pressure vessel cylinder 3 is on the upper inner wall The guide rail 8 is processed; the helium compressor 7 is placed on the upper support plate 6 inside the pressure vessel cylinder 3; the upper maintenance isolation valve 13 and the lower maintenance isolation valve 10 are installed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com