A large steel formwork designed integrated with a reserved box and its construction method

A construction method and a technology of reserved boxes, which are applied to the preparation of formwork/formwork/work frame, formwork/formwork components, and building components on site, and can solve problems such as positioning deviation and affecting the climbing of steel platform formwork. Achieve the effect of reducing the difficulty of operation, convenient processing and production, and avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

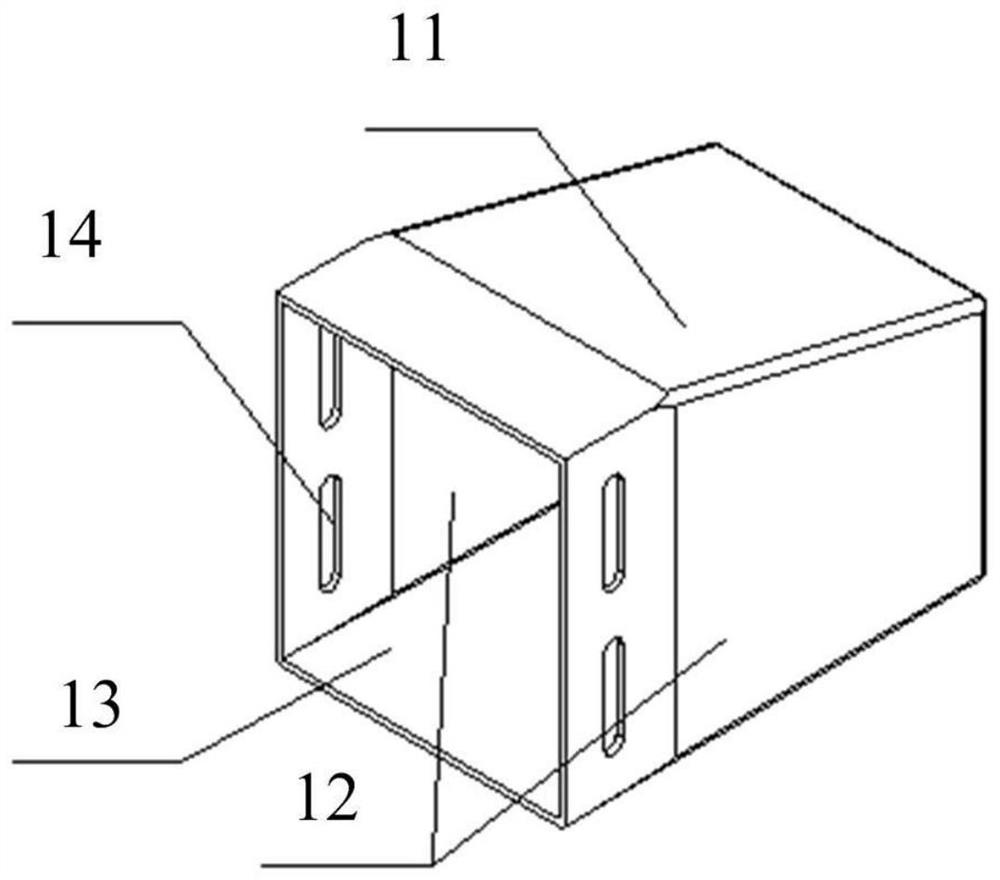

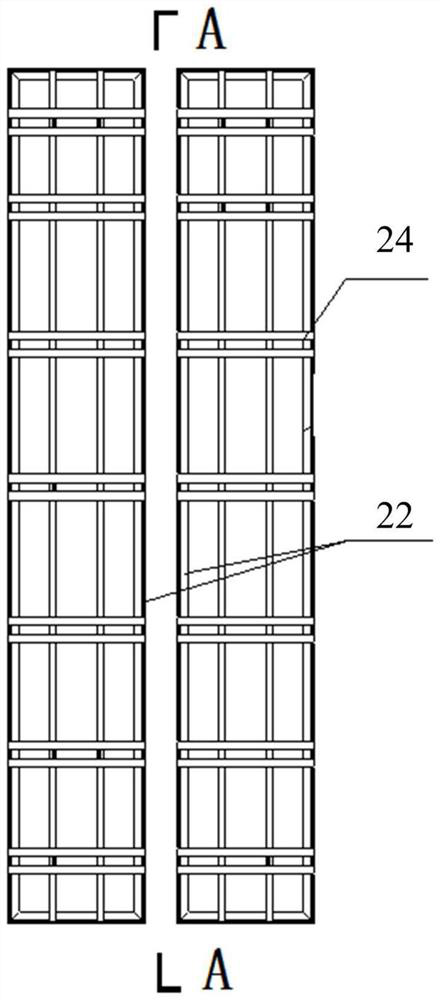

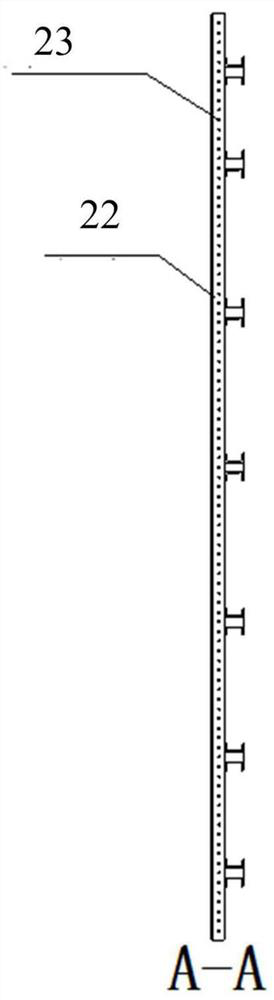

[0034] combine Figure 1 to Figure 6 The structural composition of the steel large formwork integrated with the reserved box of the present invention is described.

[0035] Please refer to Figure 1 to Figure 6 , a large steel template integrated with the reserved box, including the reserved box 10 and the template member, the two sides of the reserved box 10 are longitudinally provided with long round holes 14, and the reserved box 10 is located at the reserved hole of the corbel; the template The component includes a pair of formwork bodies and angle steel longitudinal ribs 22, the formwork body is longitudinally provided with elongated holes at positions corresponding to the corbels, the angle steel longitudinal ribs 22 are arranged on both sides of the elongated holes, and the sides of the angle steel longitudinal ribs 22 are vertical at a certain distance. Connecting holes 23 are opened to match the oblong holes 14, so that several reserved boxes 10 are sandwiched betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com