Sludge treatment system and pumping device thereof

A sludge treatment and suction device technology, applied in dehydration/drying/concentrated sludge treatment, mechanically driven excavators/dredgers, earth movers/shovels, etc., can solve the inconvenient treatment of sludge and increase transportation The burden and other problems to achieve the effect of reducing turbidity and increasing structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below in conjunction with the accompanying drawings.

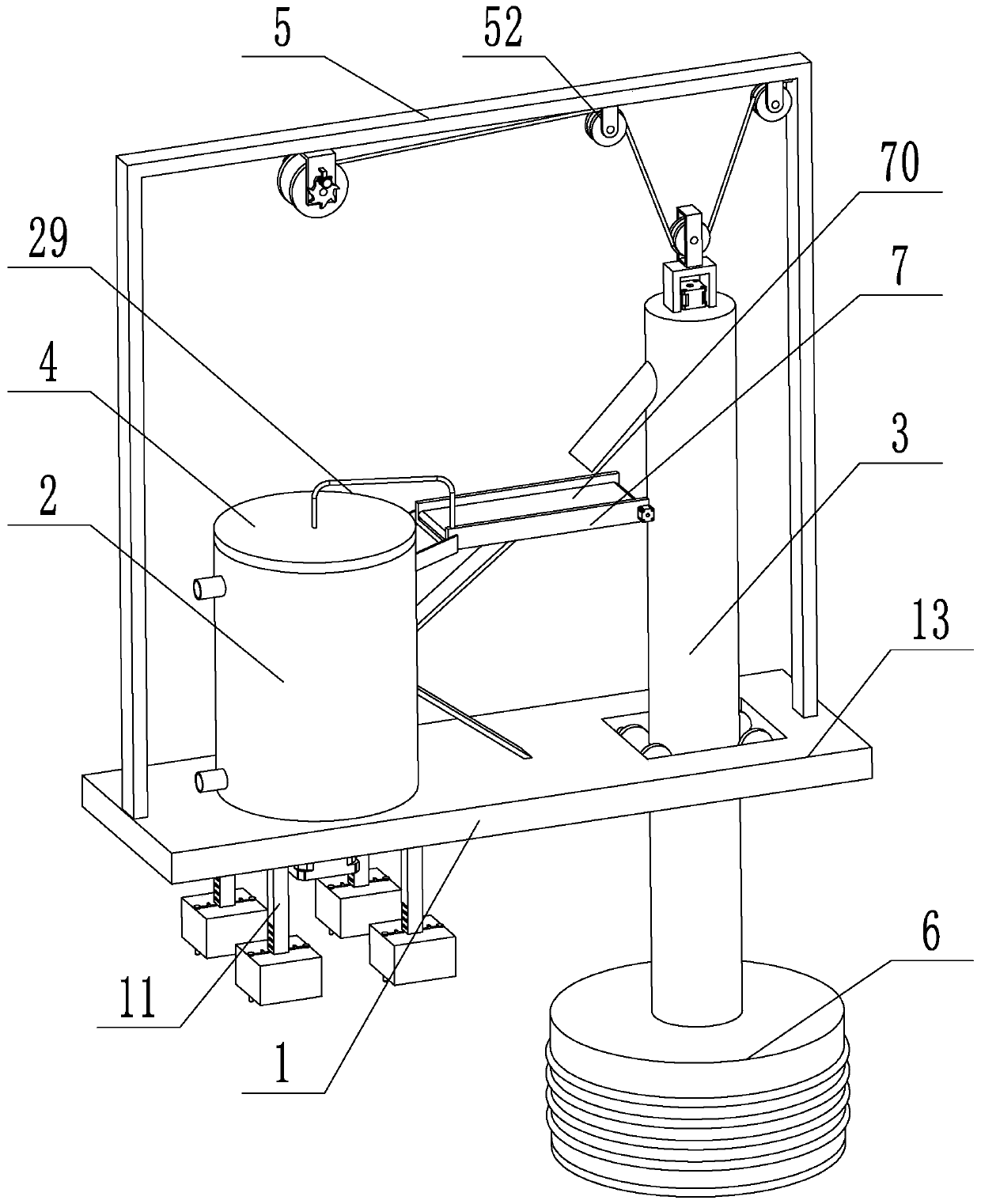

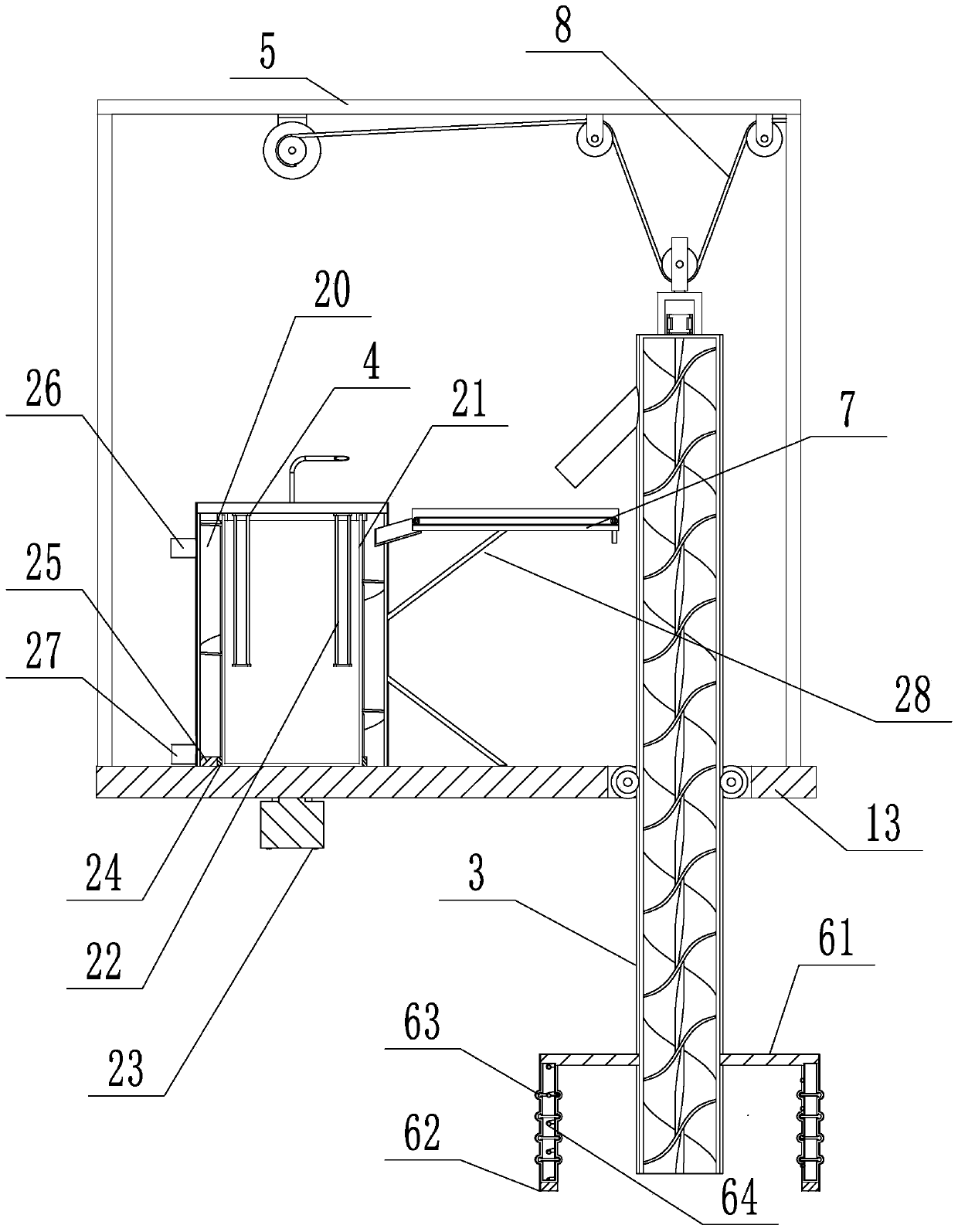

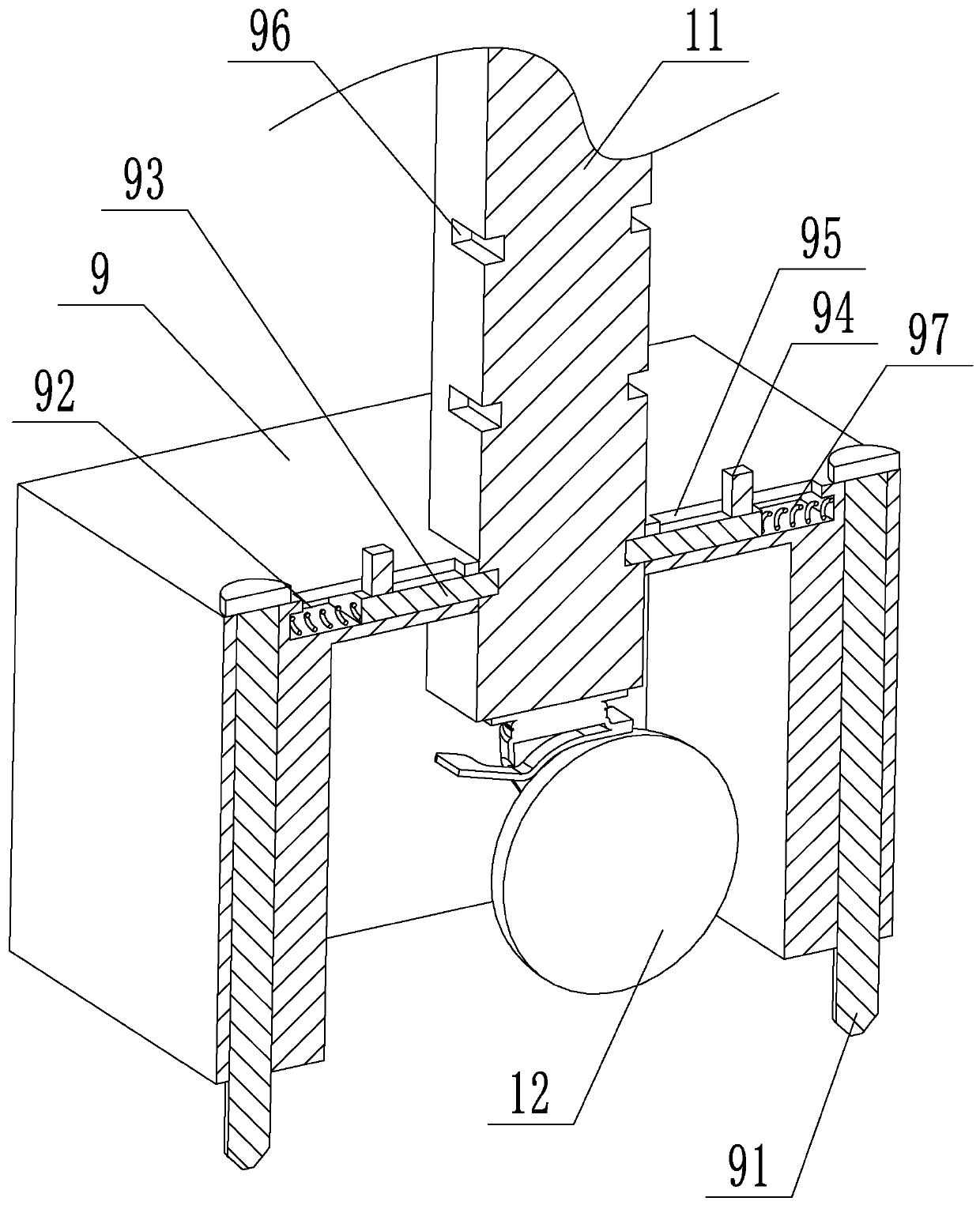

[0037] refer to figure 1 , figure 2 , is a sludge treatment system disclosed in the present invention, comprising a base 1 and a casing 2, the base 1 is connected with a suction device, the casing 2 is formed with a cavity 20 inside, and a heating cylinder 21 is rotatably installed in the cavity 20.

[0038] refer to figure 1 , figure 2 , Helical stirring blades are formed on the outside of the heating cylinder 21, a top cover 4 is installed on the top of the shell 2, a heating tube 22 is arranged on the bottom of the top cover 4 and the heating tube 22 extends into the heating cylinder 21, and the top cover 4 and the heating cylinder 21 rotate Connected, the bottom of the base 1 is provided with a driving mechanism for driving the heating cylinder 21 to rotate. The top of the cavity 20 is provided with an exhaust pipe 26 communicating with the outside,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com