Protein separation assembly and special pool

A protein separation and component technology, applied in the field of water treatment, can solve the problems of non-industrialization, no shock sterilization effect, poor protein separation effect, etc., and achieve the effect of ensuring water quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

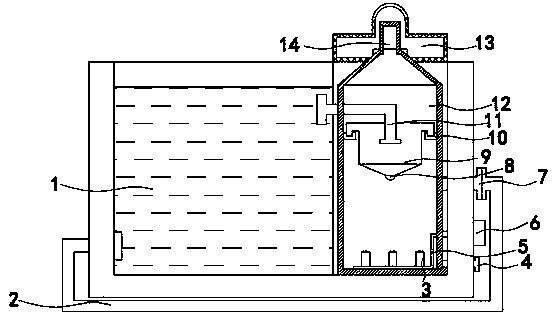

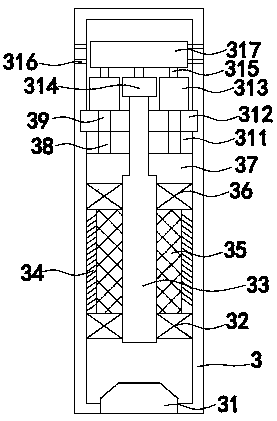

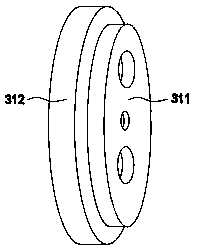

[0025] see Figure 1-4 As shown, the protein separation assembly includes an oscillating assembly 3, an inner reaction cylinder 9, and an outer reaction cylinder 12. The inner bottom surface of the outer reaction cylinder 12 is provided with at least three sets of oscillating assemblies 3, and the three sets of oscillating assemblies 3 include an internal main shaft 33, a main shaft 33 The bottom is correspondingly provided with an air inlet 31, and the bottom outer side and the middle outer side of the main shaft 33 are provided with a lower fixing ring 32 and an upper fixing ring 36, and a turbine assembly is arranged between the lower fixing ring 32 and the upper fixing ring 36, and the turbine assembly consists of a turbine The stator 34 is composed of a turbine rotor 35 . The invention can separate the protein from the culture water in the culture pond, so that the water quality of the culture water can be guaranteed, and the culture water can flow into the inner reaction...

Embodiment 2

[0033] During the actual use of the protein separation assembly and the special pool of the present invention, the water body in the culture pool 1 flows into the inner reaction cylinder 9 through the L-shaped water inlet pipe 11, and the drip hole 8 at the bottom of the inner reaction cylinder 9 will make the water body be in the shape of water droplets. In the outer reaction cylinder 12, the ozone generator 6 is opened when the water body has not crossed the shock assembly 3, and the ozone generator 6 produces ozone, and the ozone is transported from the ozone vent pipe 5 to the shock assembly 3, and the ozone entering the shock assembly 3 has a great impact on the turbine assembly. Impact, the turbine assembly drives the main shaft 33 to rotate, the main shaft 33 drives the movable valve 311 and the barrel valve 317 to rotate, and the ozone impacting the turbine assembly is collected in the first gas collection chamber 37 between the upper fixed ring 36 and the movable valve ...

Embodiment 3

[0035] In this embodiment, the protein separation components and special pools (experimental group) of the present invention and common culture pools and protein separation components (control group) on the market are tested for various indicators of the culture water after protein separation;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com