Preparation and application of an enhanced sulfate reduction composite bacteria-embedded bioactive filler

A bioactive, sulfate technology, applied in sustainable biological treatment, biological water/sewage treatment, water pollutants, etc., can solve the problems of production cost and production efficiency, difficulty in high efficiency, and high technical requirements, and achieve flow The effect of good state, improved toughness and single weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

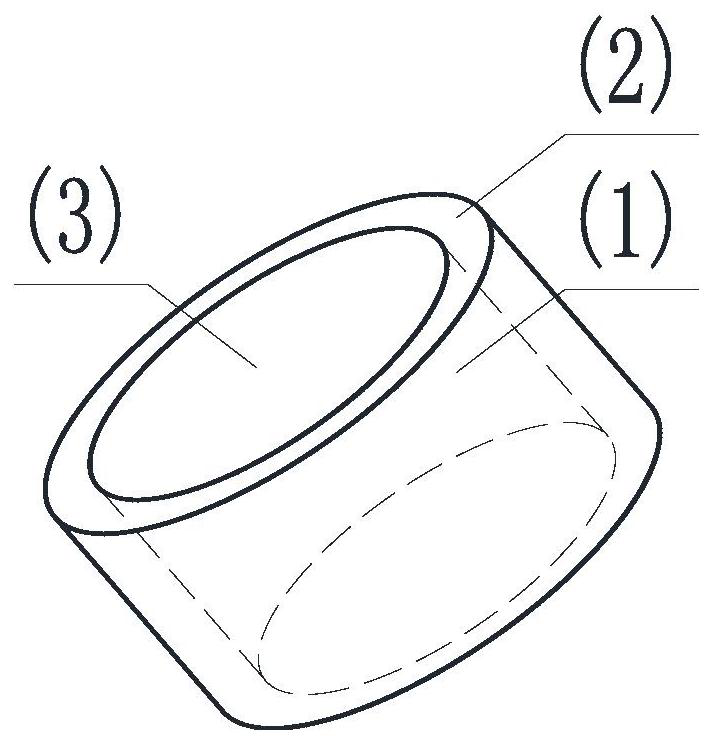

[0020] 1. Preparation of filler (1)

[0021] Oriented cultivation and strengthening of sulfate-reducing compound bacteria: take the sediment from the heavy metal sulfate wastewater storage tank, concentrate the sediment to a water content of 97%, and add it to the culture tank for sulfate-reducing bacteria. The volume is about 1 / 3 of the effective volume of the culture tank ; Under the low-intensity stirring condition of 80n / min, the water temperature is 28±2°C, and artificially prepared sulfate wastewater is added. As the concentration of sulfate in the culture tank decreases, the amount of sulfate input is continuously increased; the electron donor organic matter required for the reaction is preferably sodium lactate, and the dosage is controlled to be twice the molar amount of sulfate reduction; in this state, the detection of mixed Sulfate concentration in the culture solution; pH control at 7.5-8.5; add trace element solution 5mL / L (trace element solution composition: ZnS...

Embodiment 2

[0027] 1. Sulfate-reducing bacteria culture culture and filler preparation (same as example 1)

[0028] 2. Application of sulfate reduction embedded active filler (copper mining and smelting mixed wastewater)

[0029] Set up a reactor with an effective volume of 4000L, add 4000 sulfate reducing filler balls prepared in 1., and finally form a sulfate reducing bacteria-embedded bioactive filler with a filling rate of 20%, water temperature of 28±2°C, HRT= 8h , the pH is 8.0±0.5, the reactor feed water is copper mining and smelting wastewater, and the sulfate content is 6500-8200mg / L. The electron donor organic matter required for the reaction is sodium lactate, and the dosage is controlled to be twice the amount of sulfate reduction. A water reflux pump is installed at the end of the reactor, and the reaction liquid flows back from the end to the water inlet of the reactor (the purpose of this part is to stabilize the pH of the reactor), and the reflux ratio is 80% of the water...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com