Solid car wax waxing device

A car wax and solid technology, which is applied in grinding drive devices, vehicle maintenance, transportation and packaging, etc., can solve the problems of laborious manual operation, time-consuming and laborious, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

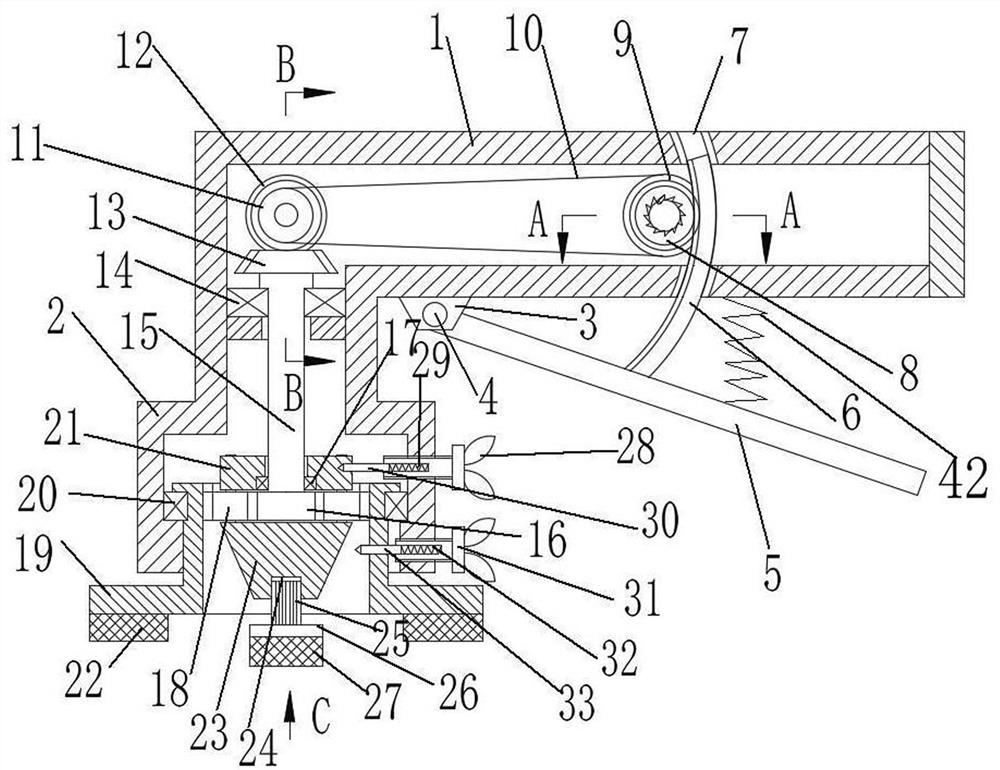

[0025] Attached below figure 1 to attach Figure 6 The present invention will be further described.

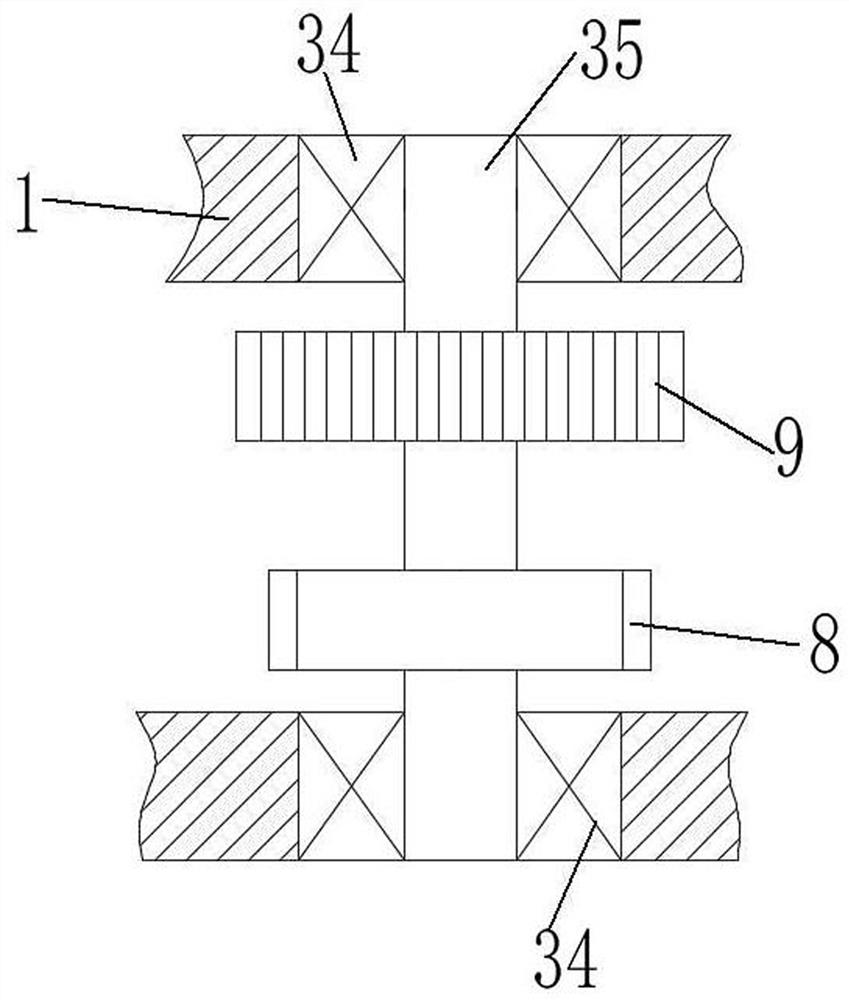

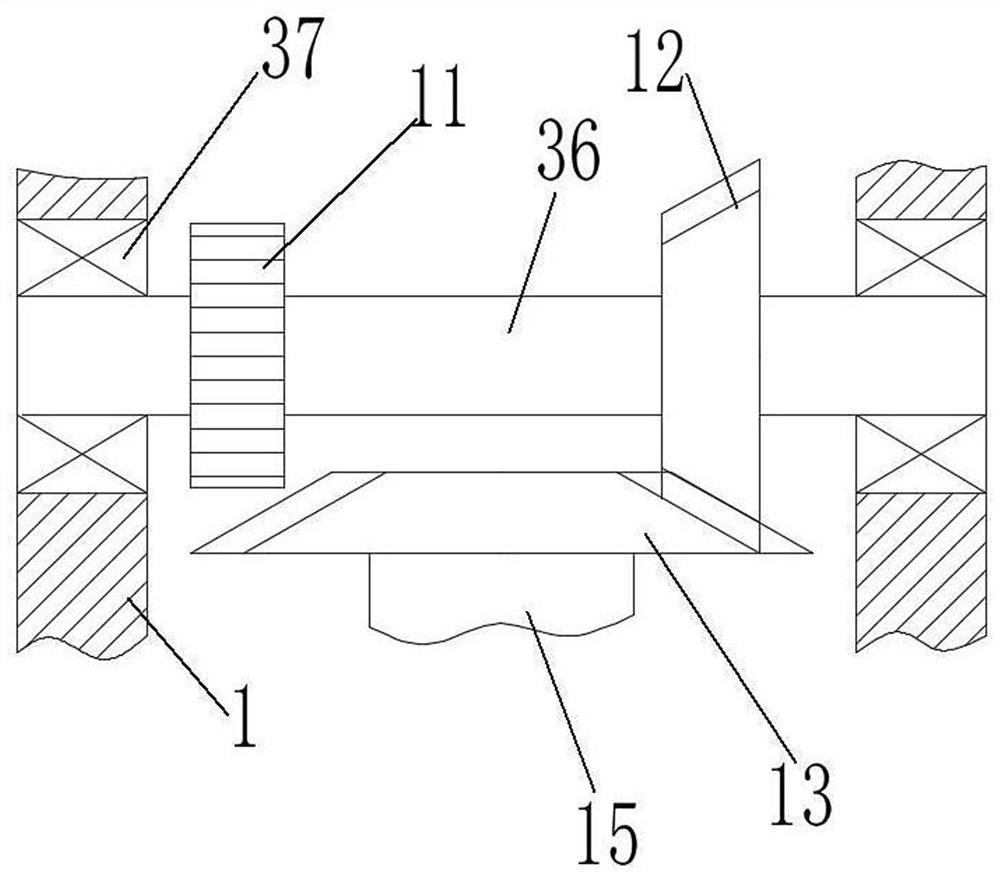

[0026] A solid car wax waxing device, comprising: a handle 1, a housing 2 is arranged under its front end, and a main shaft 15 is installed in the housing 2 to rotate vertically through a bearing I 14; an ear seat 3 is arranged on the handle 1 Below, the head end of the pressure handle 5 is hingedly mounted on the lug 3 through the pin shaft 4, one end of the spring III 42 is connected with the pressure handle 5, and the other end is connected with the handle 1; the rotating shaft I 35 is horizontally rotated and installed on the handle through the bearing IV 34 1, a gear 8 is set on the rotating shaft I 35, an arc-shaped arc gear 6 is arranged on the pressure handle 5, a guide hole 7 is arranged on the handle 1, and the arc gear 6 is inserted in the guide hole 7 and connected with the gear 8 are meshed, when the spring III 42 is in a free state, the gear 8 is meshed with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com