A kind of aluminum alloy diffusion bonding method without intermediate layer

A technology of diffusion bonding and aluminum alloy, which is applied in welding equipment, metal processing equipment, welding/welding/cutting articles, etc., can solve the problems of low joint strength, poor welding accuracy of components, and increased brittleness tendency, etc., to achieve improved interface Improve the bonding quality, welding rate, and increase the effect of deformation and crushing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

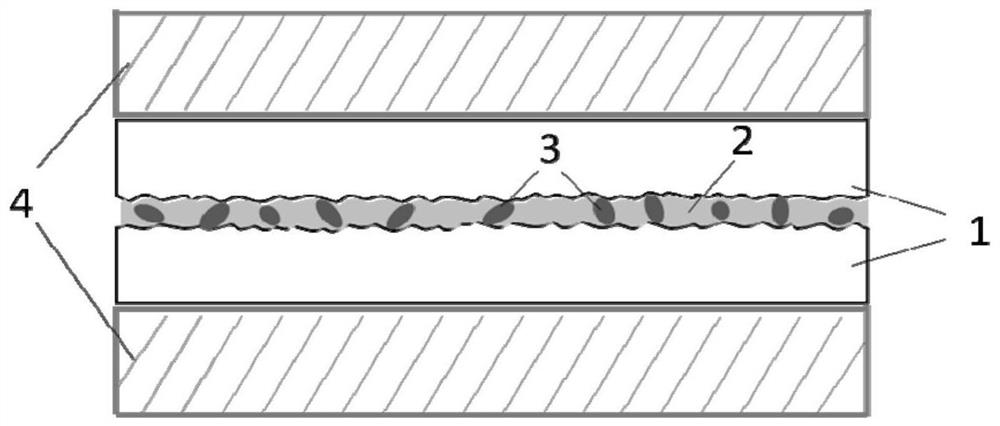

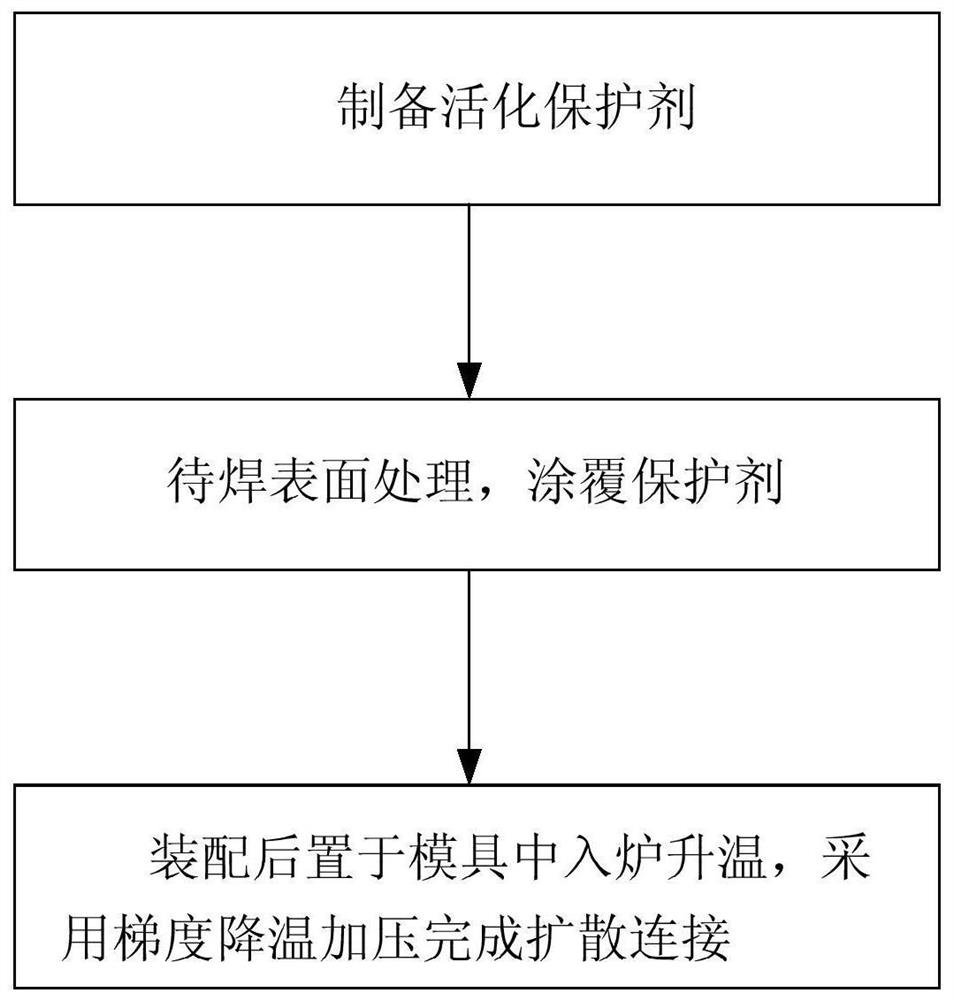

[0033] After cleaning and degreasing the surface of the aluminum alloy to be welded, use sandpaper to polish the surface to be welded to remove the oxide film, and form a surface with a roughness of Ra0.8. Use sandblasting to form uniform and fine micron-scale pits on the surface, and then pass through alcohol ultrasonic waves. Cleaning further removes surface impurities. Apply a layer of activation protectant immediately after treatment and cleaning. The activation protective agent is prepared by mixing pure magnesium powder and diethylene glycol dimethyl ether, wherein the mass percent of the pure magnesium powder is 2%, and the rest is diethylene glycol dimethyl ether. The particle size of the pure magnesium powder in the activation protective agent is 30 μm, and uniformly mixed in proportion to prepare the activation protection agent. The two surfaces to be welded coated with the activation protective agent are assembled and put into the upper and lower molds, and the who...

Embodiment 2

[0035]After cleaning and degreasing the surface of the aluminum alloy to be welded, use sandpaper to polish the surface to be welded to remove the oxide film, and form a surface with a roughness of Ra0.8. Use sandblasting to form uniform and fine micron-scale pits on the surface, and then pass through alcohol ultrasonic waves. Cleaning further removes surface impurities. Apply a layer of activation protectant immediately after treatment and cleaning. The activation protection agent is prepared by mixing pure magnesium powder and diethylene glycol dimethyl ether, wherein the mass percent of the pure magnesium powder is 3%, and the rest is diethylene glycol dimethyl ether. The particle size of the pure magnesium powder in the activation protection agent is 40 μm, and uniformly mixed in proportion to prepare the activation protection agent. The two surfaces to be welded coated with the activation protective agent are assembled and put into the upper and lower molds, and the whol...

Embodiment 3

[0037] After the surface of the aluminum alloy to be welded is cleaned and degreasing, the surface to be welded is polished with sandpaper to remove the oxide film, and a surface with a roughness of Ra1.6 is formed. Cleaning further removes surface impurities. Apply a layer of activation protectant immediately after treatment and cleaning. The activation protective agent is prepared by mixing pure magnesium powder and diethylene glycol dimethyl ether, wherein the mass percent of the pure magnesium powder is 4%, and the rest is diethylene glycol dimethyl ether. The particle size of the pure magnesium powder in the activation protective agent is 50 μm, and uniformly mixed in proportion to prepare the activation protection agent. The two surfaces to be welded coated with the activation protective agent are assembled and put into the upper and lower molds, and the whole is put into the vacuum furnace. Vacuum the furnace body to 5×10 -3 After Pa, the heating was started, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com