A double shield tbm pipe back support method for rockburst

A double-shield and rockburst technology, applied in earthwork drilling, shaft equipment, wellbore lining, etc., can solve the problems of quality and safety accidents, brittle failure of rigid support structures, etc., and reduce the impact of rock block ejection impact damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with accompanying drawing:

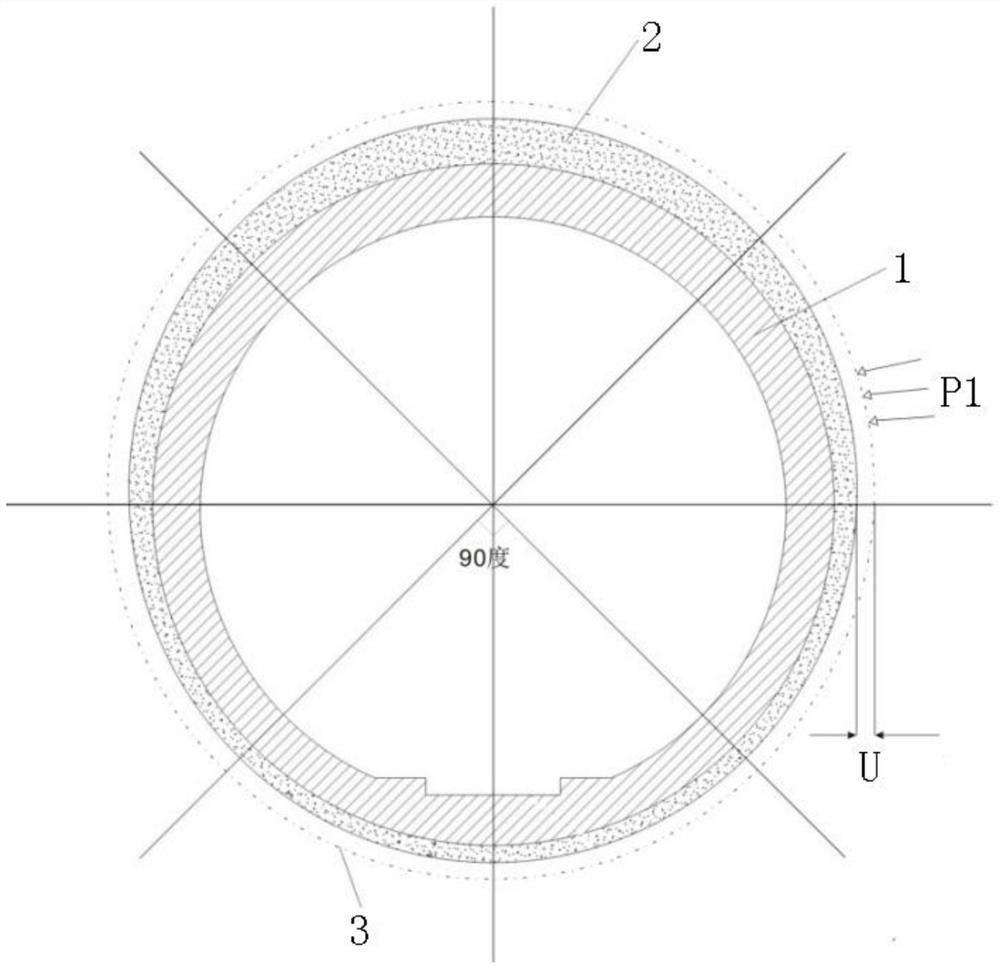

[0033] Such as Figure 6 As shown, a double-shield TBM pipe back support method for dealing with rockbursts includes the following steps:

[0034] S1. Construction preparation;

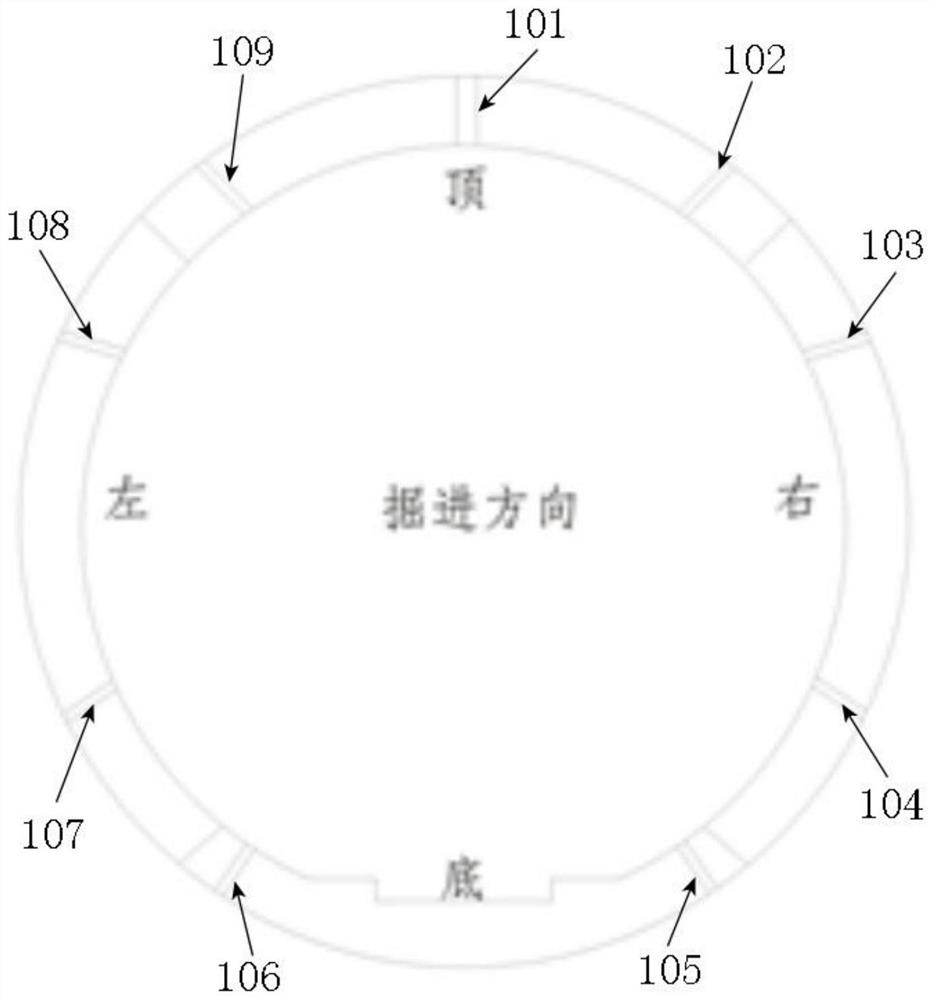

[0035] S2. Prefabricated segment installation;

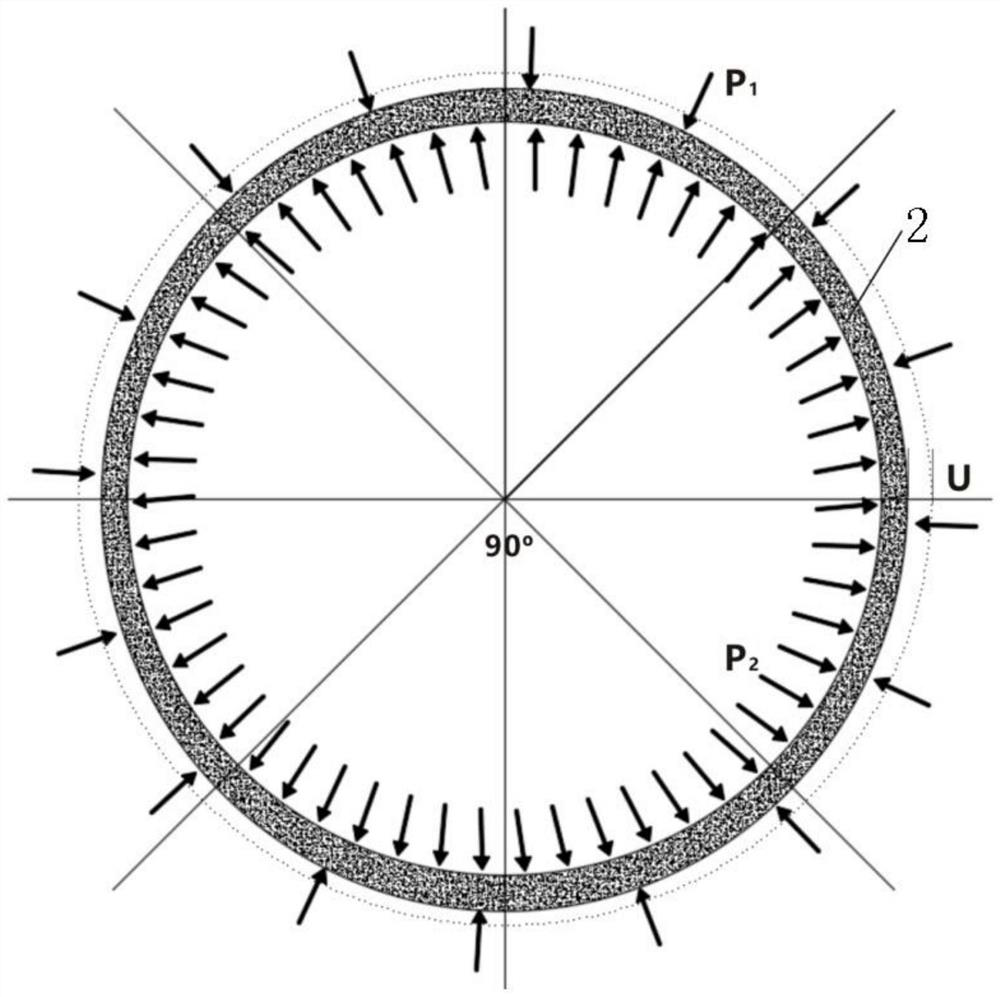

[0036] S3, the delay time t1, after the unloading of the surrounding rock slows down and the deformation decreases, the bean gravel backfill is carried out;

[0037] S4. Delay time T. After the stress field and crack development are completed during the rockburst buffer period of the bean gravel layer, the cement slurry is poured.

[0038] Specifically, step S1 includes: prepare pea gravel, cement and sand according to engineering requirements, and perform performance inspection on the air compressor and pea gravel injector equipment; choose bean gravel with a particle size of 4-6 mm for the dredging material Good energy dissipation characteristi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com