Plastic building template

A construction formwork and plastic technology, which is applied in the direction of construction, building structure, formwork/formwork components, etc., can solve the problems of reduced service life of plastic building formwork and influence of core plate strength, etc., so as to improve service life, improve pouring efficiency, The effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

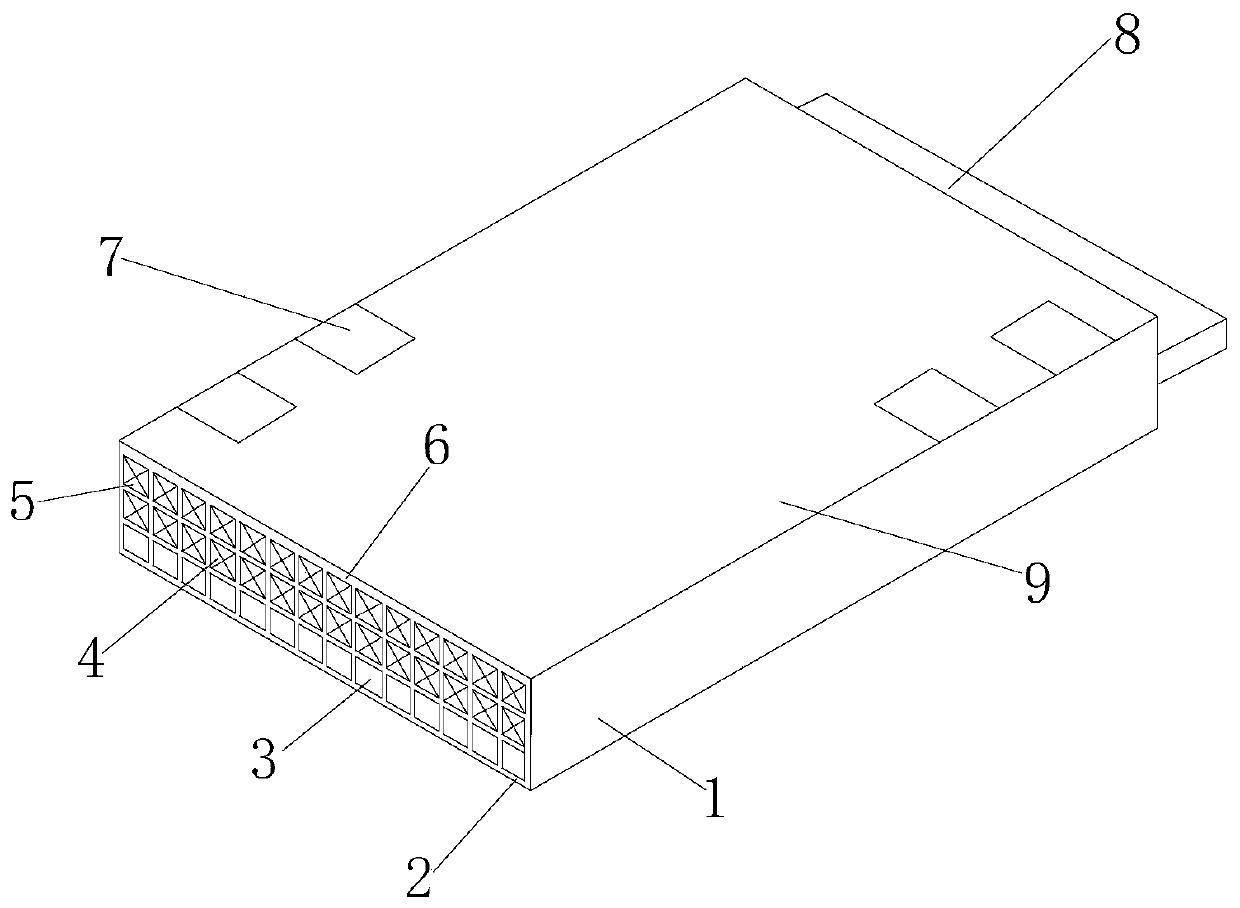

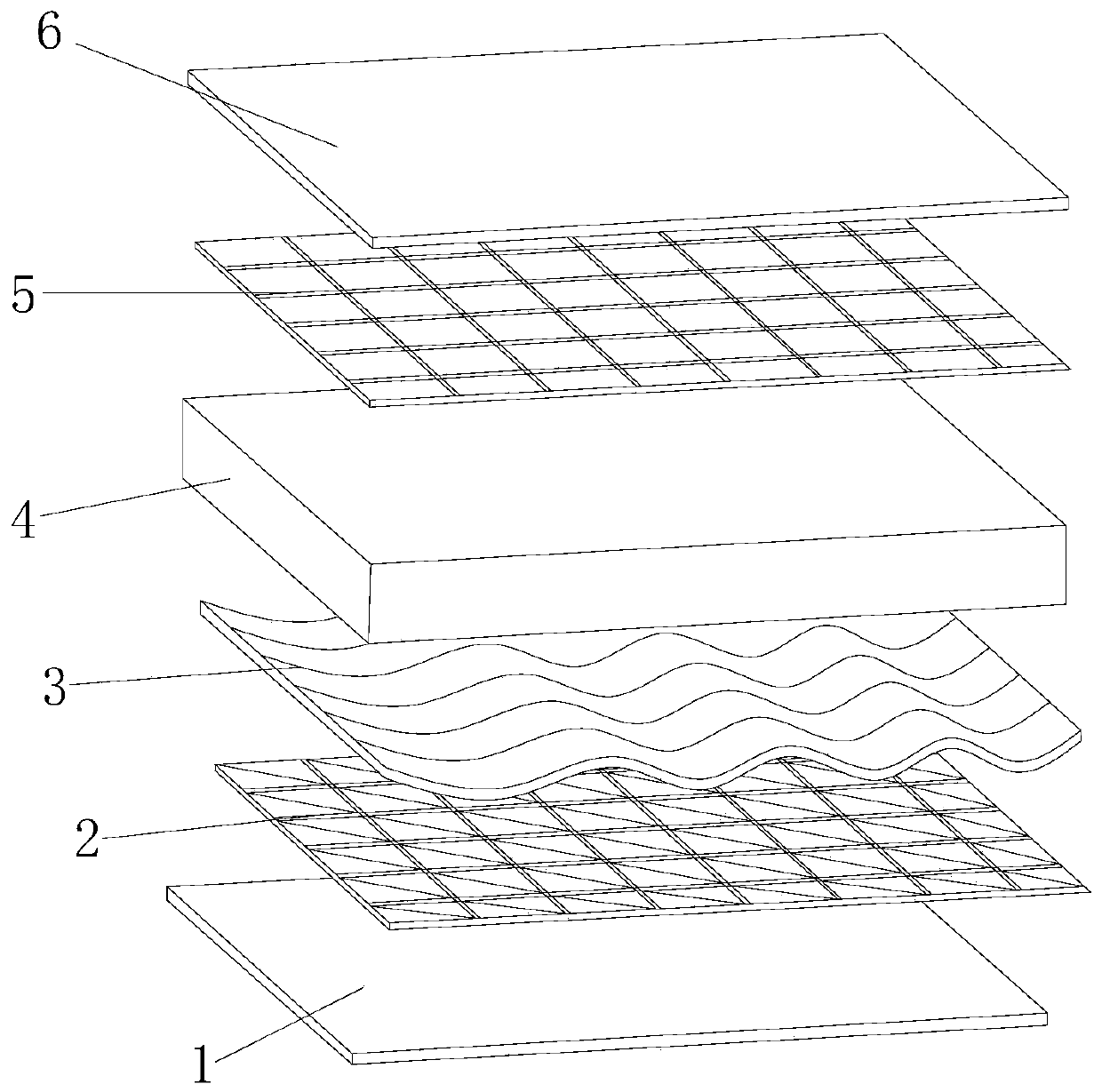

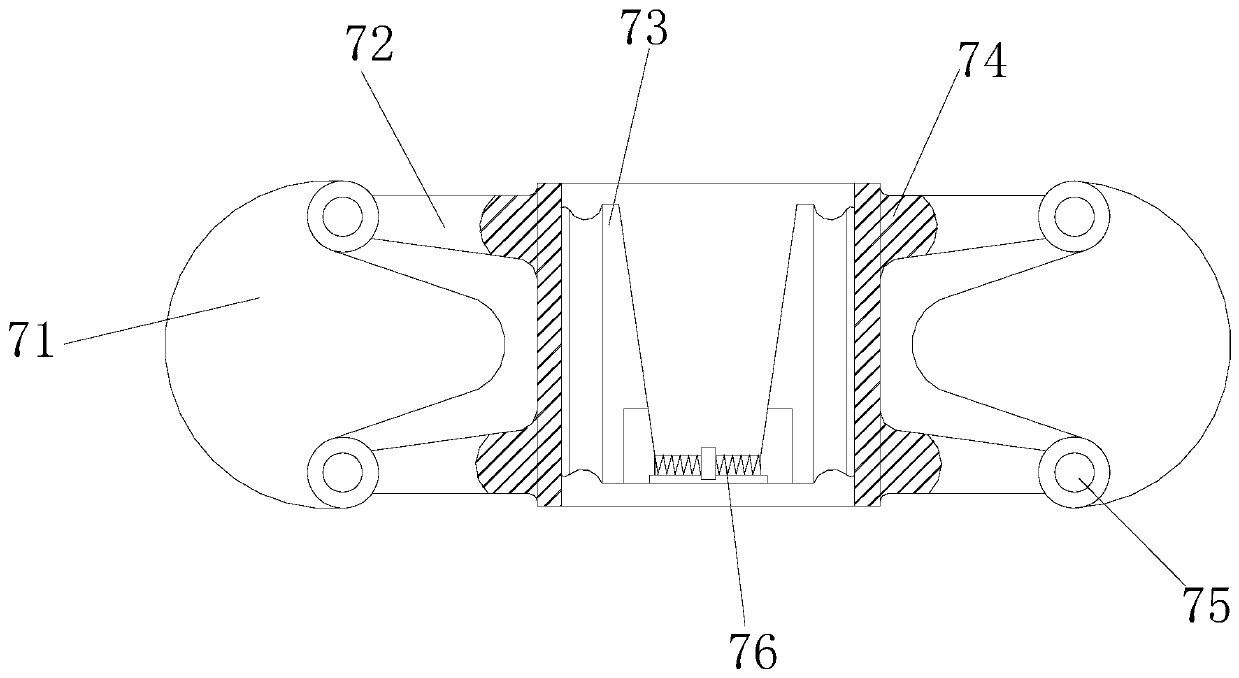

[0032] see Figure 1-2 , the present invention provides a technical solution: a plastic building formwork, the structure of which includes a lower plastic surface layer 1, a glass fiber mesh layer 2, an insulating heat-absorbing sheet 3, a PP plastic core layer 4, an elastic cushion layer 5, and an upper plastic surface layer 6 , pulling device 7, sealing device 8, main body 9, described lower plastic surface layer 1 is provided with glass fiber mesh layer 2, and described glass fiber mesh layer 2 is arranged at the bottom of isolation heat absorbing sheet 3, and described isolation heat absorbing sheet 3. The top is superimposed on the bottom of the PP plastic core layer 4. The PP plastic core layer 4 is connected to the elastic cushion layer 5 in a laminating manner. The upper end of the elastic cushion layer 5 is connected to the upper plastic surface layer 6. The upper plastic surface layer 6 is connected to the PP plastic core layer 4 through the elastic cushion layer 5, ...

Embodiment 2

[0039] see Figure 1-2 , the present invention provides a technical solution: a plastic building formwork, the structure of which includes a lower plastic surface layer 1, a glass fiber mesh layer 2, an insulating heat-absorbing sheet 3, a PP plastic core layer 4, an elastic cushion layer 5, and an upper plastic surface layer 6 , pulling device 7, sealing device 8, main body 9, described lower plastic surface layer 1 is provided with glass fiber mesh layer 2, and described glass fiber mesh layer 2 is arranged at the bottom of isolation heat absorbing sheet 3, and described isolation heat absorbing sheet 3. The top is superimposed on the bottom of the PP plastic core layer 4. The PP plastic core layer 4 is connected to the elastic cushion layer 5 in a laminating manner. The upper end of the elastic cushion layer 5 is connected to the upper plastic surface layer 6. The upper plastic surface layer 6 is connected to the PP plastic core layer 4 through the elastic cushion layer 5, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com