Steel plate-concrete composite shear wall and connecting structure thereof and construction method thereof

A combination of shear wall and steel plate concrete technology, which is applied in the direction of walls, building components, building structures, etc., can solve the problems that the prefabricated construction requirements cannot be realized, the quality of sleeve grouting is difficult to guarantee, and the amount of steel used in shear walls is large. , to avoid the exposure of the interface, meet the aesthetic requirements, and achieve good ductility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

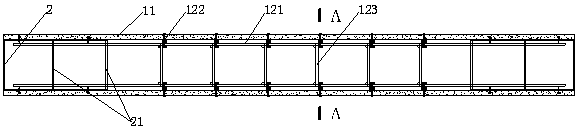

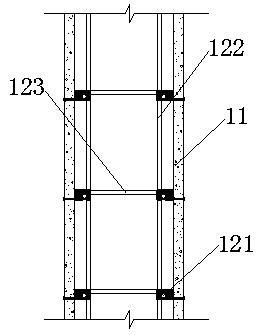

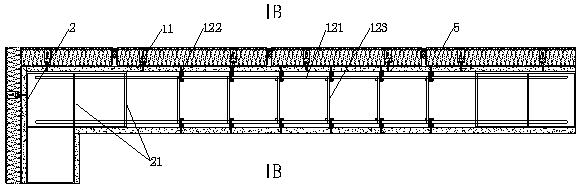

[0042] See Figure 1-Figure 5 , A steel plate-concrete composite shear wall, comprising a wall 1 and an edge member 2. The wall 1 and the edge member 2 integrally form a composite wall leg, and the composite wall leg is filled with concrete. The wall 1 includes two side templates 11 and a reinforcing steel frame 12 located between the two side templates 11. The reinforcing steel frame 12 is fixed to the two side templates 11 through connecting pieces. The reinforcing steel skeleton 12 includes horizontally distributed ribs 121, vertical distributed ribs 122, and web bars 123. There are two horizontally distributed ribs 121 located on the same horizontal plane, and the web bars 123 are distributed at two intervals along the length of the horizontally distributed bars 121. There are several horizontally distributed ribs 121, and the two ends of the web member 123 are welded and fixed to the two horizontally distributed ribs 121 respectively, so as to ensure the relative distance ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com