Polyglycolic acid modifier, composition and preparation method and use thereof

A technology of polyglycolic acid and modifier, applied in the field of polyglycolic acid composition and its preparation, can solve the problems of improving the hydrophobicity and mechanical properties of polyglycolic acid, no rare earth polymer additives have been found, and achieve good hydrophobicity Associativity, improving compatibility and machinability, reducing the effect of agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0052] According to one embodiment of the present invention, polyglycolic acid modifier comprises:

[0053] Component A

[0054] 1 to 15 parts by weight of rare earth additives;

[0055] Component B

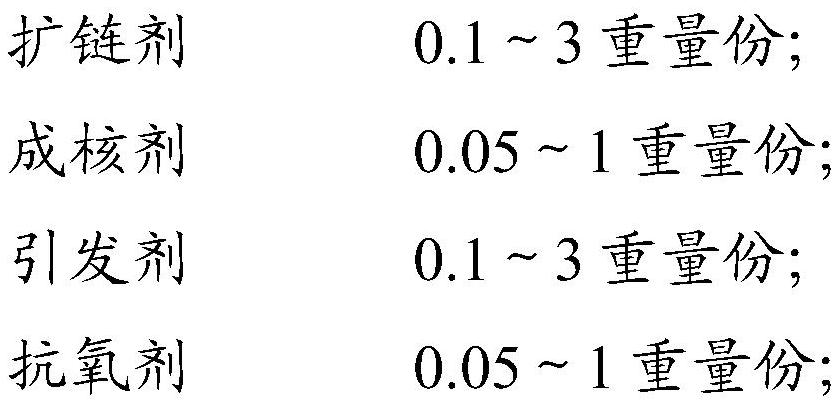

[0056]

[0057] According to another embodiment of the present invention, polyglycolic acid modifier comprises:

[0058] Component A

[0059] 2 to 10 parts by weight of rare earth additives;

[0060] Component B

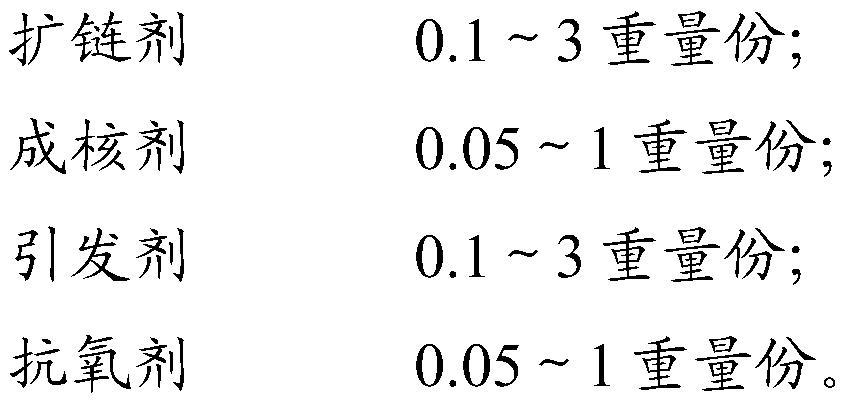

[0061]

[0062] According to another embodiment of the present invention, polyglycolic acid modifier comprises:

[0063] Component A

[0064] 2 to 6 parts by weight of rare earth additives;

[0065] Component B

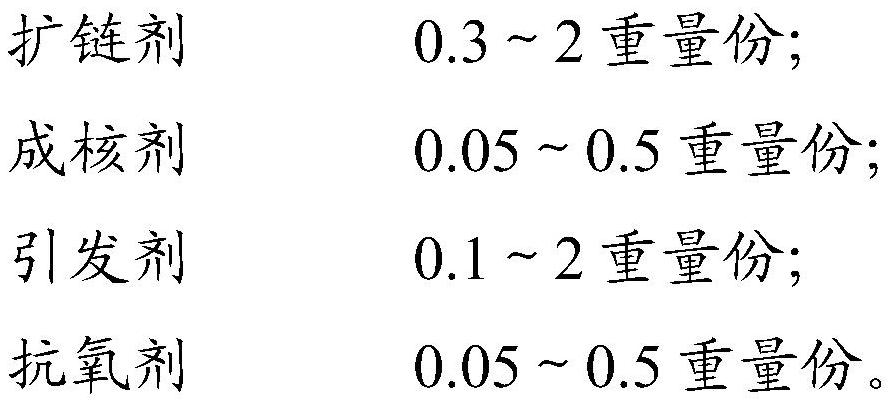

[0066]

[0067]

[0068] The preparation method of polyglycolic acid modifier of the present invention comprises the steps:

[0069] (1) reacting a cationic surfactant with a rare earth salt compound to obtain an organic rare earth compound; reacting an organic rare earth compound with a coupling agent to obtain component A;

[0070] (2) Mi...

Embodiment 1~3

[0103] Under the condition of 50°C water bath, dissolve the cationic surfactant in acetic acid, stir at 55°C for 32min to form a mixed solution; slowly add rare earth carbonate to the mixed solution, first react at 55°C for 70min, then at 70°C The reactant was reacted at ℃ for 1.5h to obtain the reactant; the reactant was dried at 60°C for 3.5h to obtain the organic rare earth compound.

[0104]Mix the coupling agent with an ethanol solvent to obtain a mixed solution, then add acetic acid to adjust the pH of the mixed solution to 5; stir the pH-adjusted mixed solution at 50°C for 450 minutes to obtain a coupling agent solution; slowly add the organic rare earth compound to the In the coupling agent solution, react at 50° C. for 1 h, dry and grind into powder to obtain component A.

[0105] Mix nucleating agent, chain extender, initiator and antioxidant to obtain component B.

[0106] The specific materials and amounts used are shown in Table 1.

[0107] Table 1

[0108] ...

Embodiment 4

[0110] (1) 87 parts by weight of polyglycolic acid and component A obtained in Example 1 are blended and banburyed in a banbury mixer, and then granulated to obtain polyglycolic acid particles; the banburying temperature is 210° C., and the banburying time is 8min, the screw speed of the internal mixer is 70rpm.

[0111] (2) The polyglycolic acid particles were blended with the component B prepared in Example 1, and extruded through a twin-screw extruder to obtain a polyglycolic acid composition. The extrusion temperature was 210° C., and the screw speed of the twin-screw extruder was 40 rpm. The properties of the polyglycolic acid composition are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com