A kind of polypropylene resin specially used for high-speed biaxially stretched film and its preparation method and application

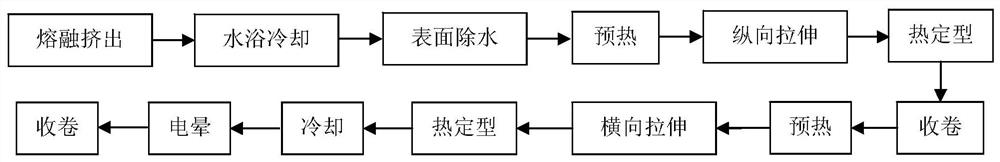

A biaxially oriented film and polypropylene resin technology, applied in the field of olefin polymerization, can solve the problems of serious thermal and oxygen aging of resin, short screen changing cycle, complex asymmetric hydrogenation step-by-step polymerization operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Ziegler-Natta catalyst (SHAC) TM 201, including titanium tetrachloride, carrier magnesium chloride and internal electron donor phthalate), in the presence of cocatalyst triethylaluminum and external electron donor n-propyltrimethoxysilane, at a polymerization temperature of 70 ℃, polymerization pressure 3.2MPa and appropriate hydrogen flow rate 1.5kg / h, adjust and control the flow rate of the catalyst carrier to 80kg / h, the feed rate of propylene is 58000kg / h, and the molar ratio of aluminum to silicon is 9, that is, The ratio of the catalyst to the external electron donor, calculated as the molar ratio of aluminum to titanium, is 52, that is, the ratio of the cocatalyst to the Ziegler-Natta catalyst, and the polypropylene powder is prepared.

Embodiment 2

[0034] Ziegler-Natta catalyst (SHAC) TM 201, including titanium tetrachloride, carrier magnesium chloride and internal electron donor phthalate), in the presence of cocatalyst triethylaluminum and external electron donor n-propyltrimethoxysilane, at a polymerization temperature of 70 ℃, polymerization pressure 3.2MPa and appropriate hydrogen flow rate 1.5kg / h, adjust and control catalyst carrier flow rate 80kg / h, propylene feed rate is 58000kg / h, and the molar ratio of aluminum to silicon is 6, that is, The ratio of the catalyst to the external electron donor, calculated as the molar ratio of aluminum to titanium, is 52, that is, the ratio of the cocatalyst to the Ziegler-Natta catalyst, and the polypropylene powder is prepared.

Embodiment 3~4

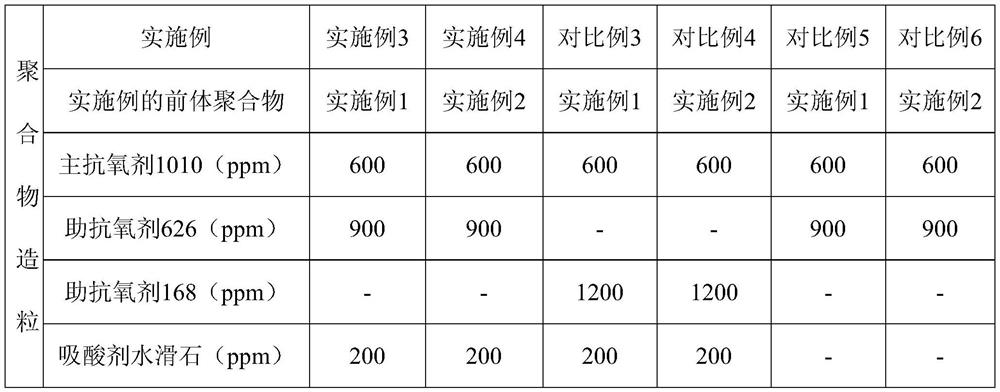

[0039] Embodiment 3~4 and comparative example 3~6

[0040]On the basis of the above-mentioned Examples 1-2, in the presence of the following additives, the polypropylene powder is melt-extruded and granulated with a twin-screw extruder at a temperature of 210-240°C to prepare Examples 3-4 and Ratio 3-6, wherein each component should be respectively: polypropylene powder, primary antioxidant tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester (1010 ), co-antioxidant bis (2.4-di-tert-butylphenyl) pentaerythritol diphosphite (626) or tris (2,4-di-tert-butylphenyl) phosphite (168), hydrotalcite (DHT -4A) or calcium stearate (CaSt), then carry out underwater ring cutting and granulation, and the temperature of the granulation water is 60°C. The specific addition amount of the above-mentioned additives is the amount recorded in Table 1 below.

[0041] The raw material components of table 1 embodiment 3~4 and comparative example 3~6

[0042]

[0043...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| tensile yield strength | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com