Cable collecting device capable of automatically arranging cables

A collection device and automatic wire arrangement technology, which is applied in transportation and packaging, delivery of filamentous materials, and thin material processing, etc., can solve problems such as complex structure, affecting equipment reliability, and inconsistency between the wire arrangement wheel and the winding position, etc. Achieve the effect of high wiring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the drawings and embodiments, but it is not used as a basis for any limitation on the invention.

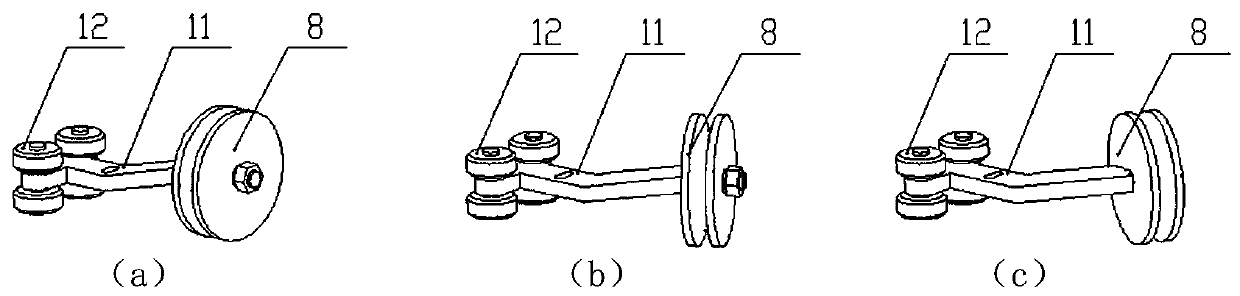

[0026] This embodiment is an accessory part used for fuel transportation equipment, which requires extremely high operating precision. The tipping mechanism uses a hoist to drive a steel wire rope to overturn the fuel basket, and relies on the rotation angle of the hoist to judge the movement length of the wire rope, and then determine the fuel basket. The tipping angle of the basket can realize the precise control of the position. At present, this device relies on the extrusion of steel wire ropes to arrange the wires. The friction between the steel wire ropes is relatively large, and the wear of the steel wire ropes is relatively fast. The use of the cable collection device of the present invention can effectively solve the problems of automatic cable arrangement and winding wear of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com