Transfer trolley for quilting quilts

A turnover car, quilting technology, applied in trolleys, motor vehicles, multi-axle trolleys, etc., can solve the problems of quilting dirty, inconvenient, slipping, etc., to avoid the effect of mopping the floor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

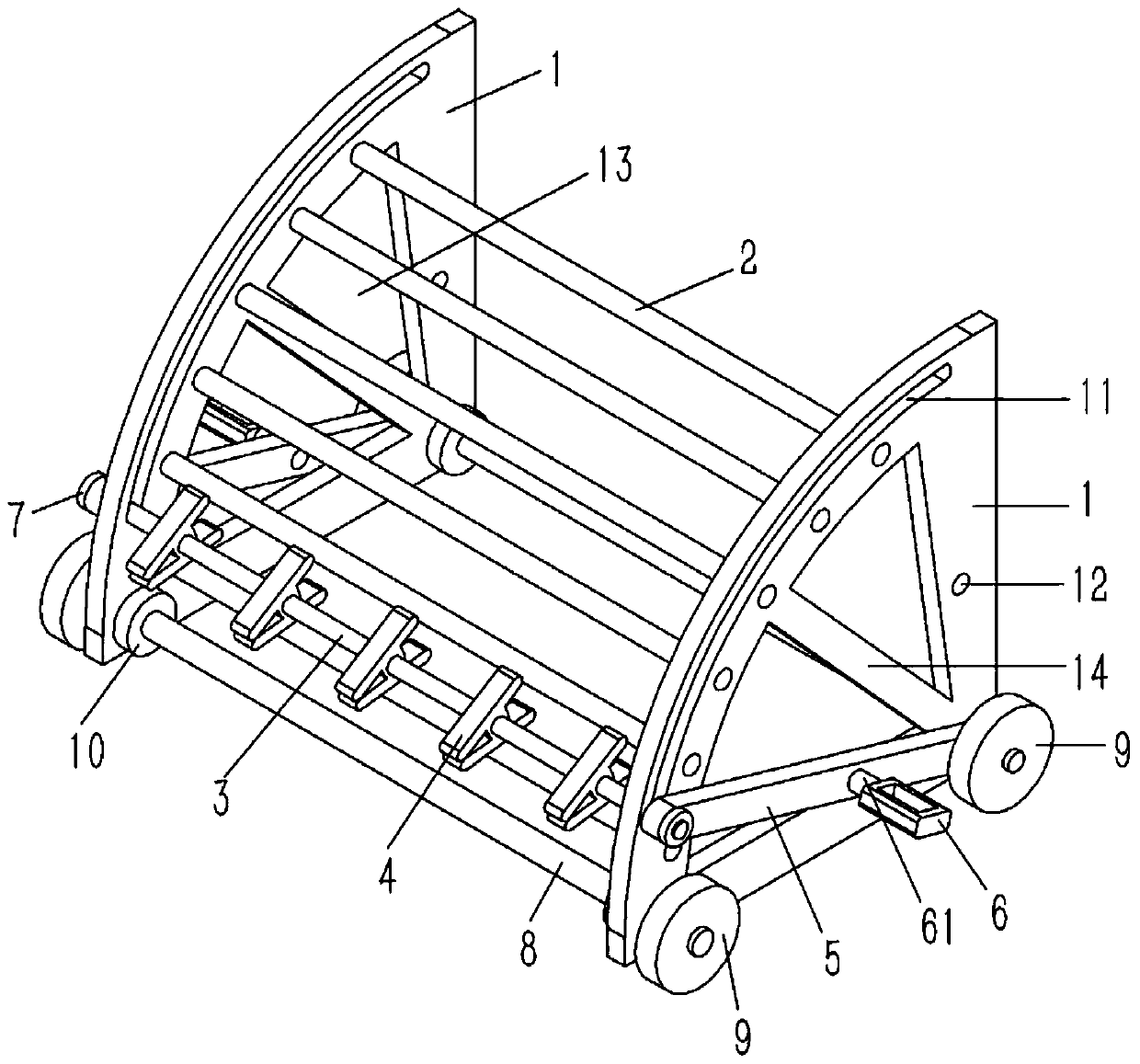

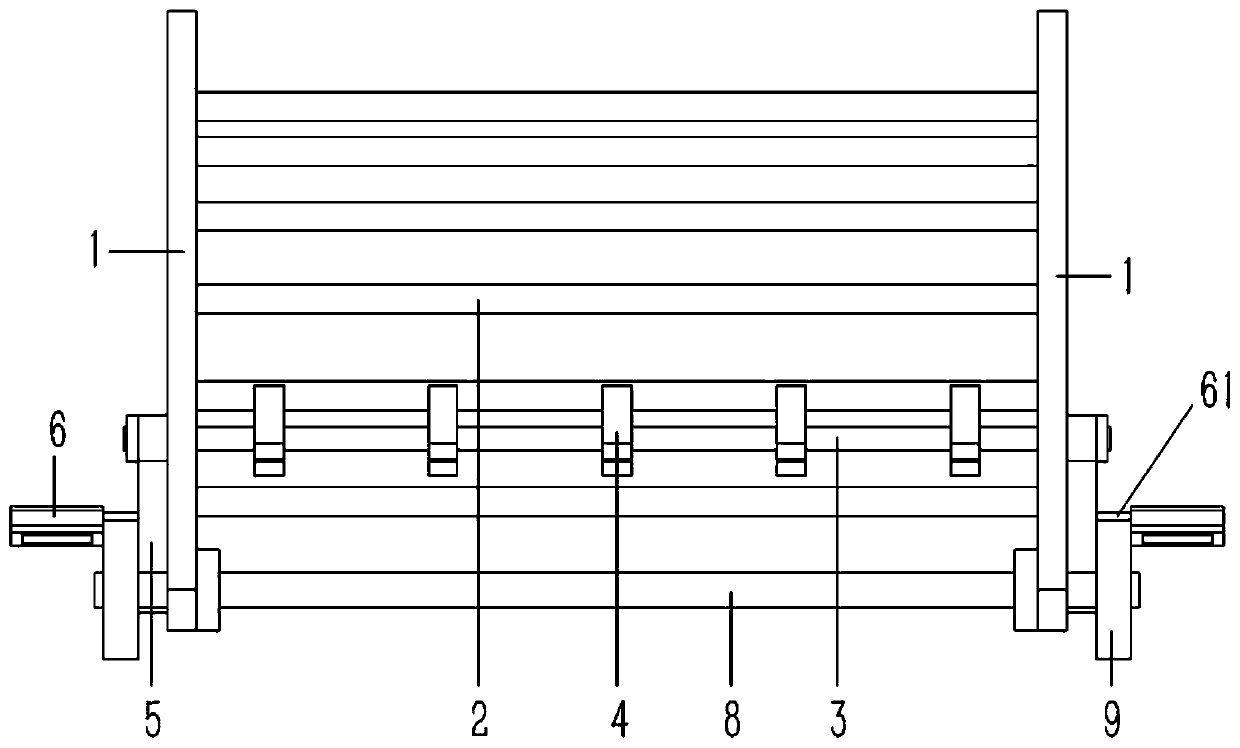

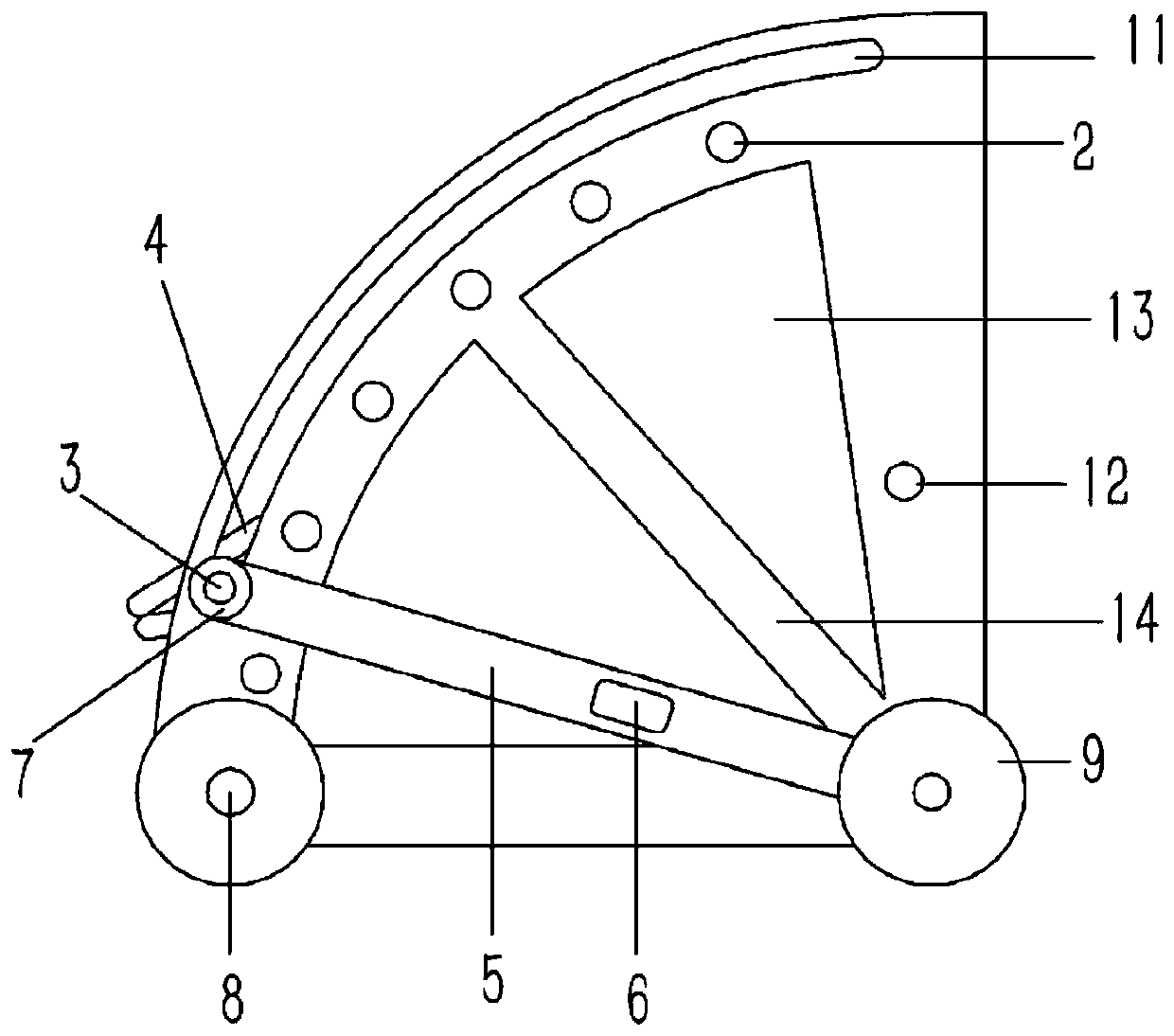

[0018] Example: see Figures 1 to 3 As shown, a turnover vehicle for quilting is carried, including two sets of quarter-circle side support plates 1, and one side of the arc edge of the side support plates 1 is formed with an arc with the same center as the side support plate 1 Shaped guide groove 11, between side support plate 1 is inserted with draw bar 3 and some support bars 2, the two ends of support bar 2 are plugged and fixed on the side support plate 1 and are distributed in the inner side of arc-shaped guide groove 11; Several clips 4 are fixedly connected to the draw bar 3, and the two ends of the draw bar 3 pass through the arc-shaped guide groove 11 of the side support plate 1 and are inserted on the drive bar 5, and the end of the drive bar 5 is inserted into the On the axle 8, the front and rear ends of the lower part of the side support plate 1 are plugged on the axle 8, and the two ends of the axle 8 stretch out from the outer side wall of the side support plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com