Auxiliary fixing device used for model making

A technology of fixing devices and models, which is applied to the devices for coating liquid on the surface, manufacturing tools, and parts of grinding machine tools, etc., which can solve the problems of inconvenient operation, low processing efficiency, and difficulty in quickly adjusting the inclination angle of parts to achieve fast Adjustment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

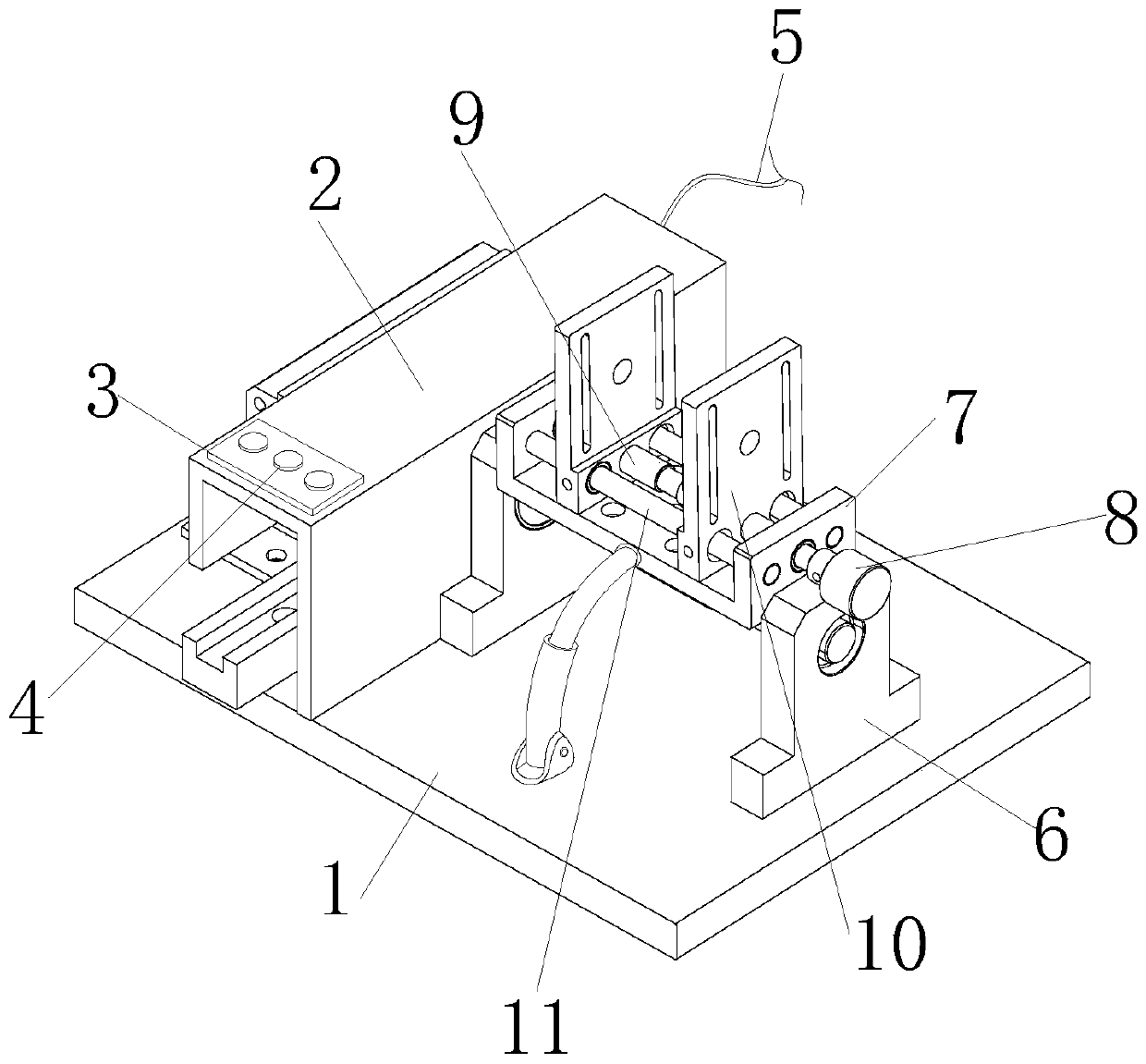

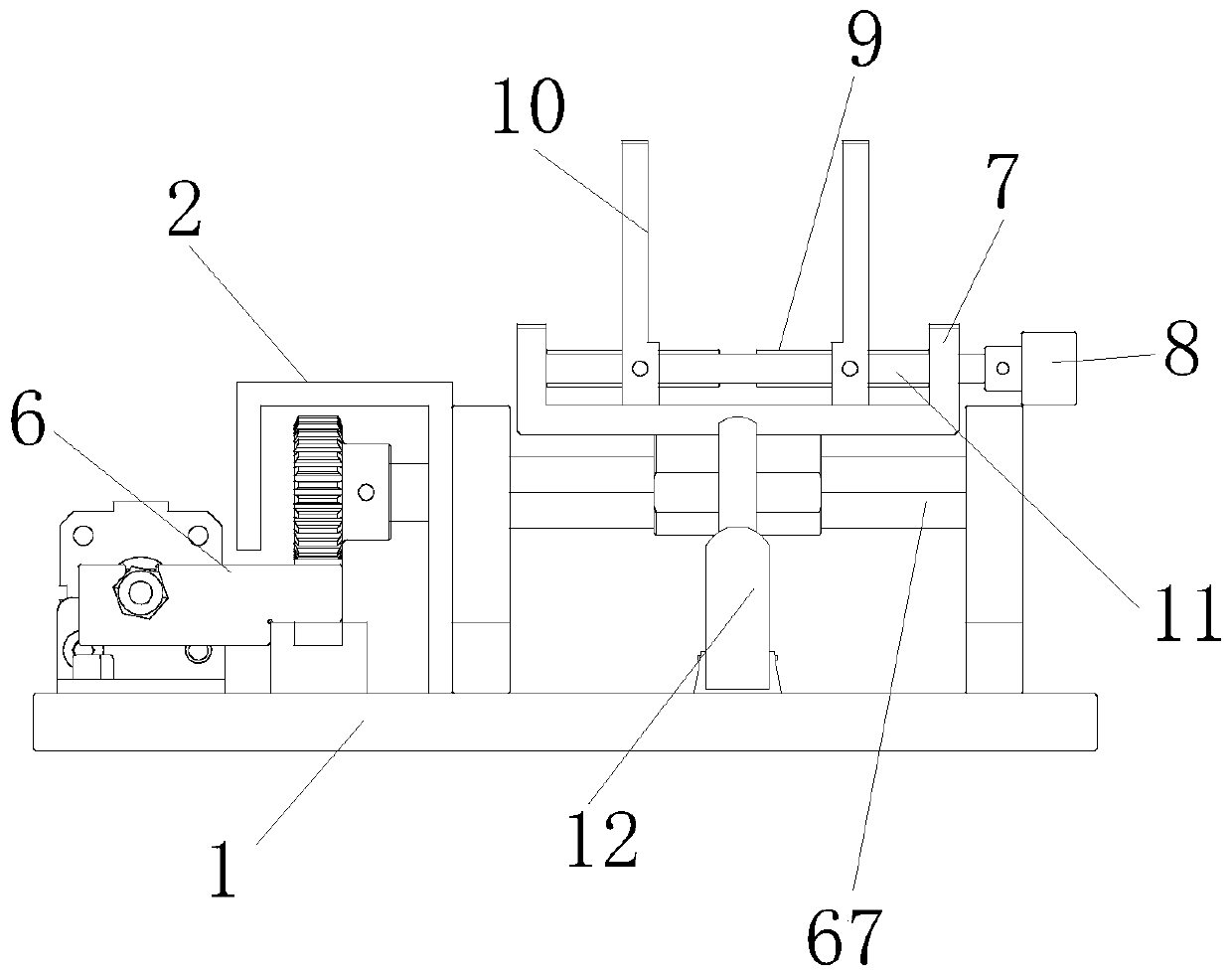

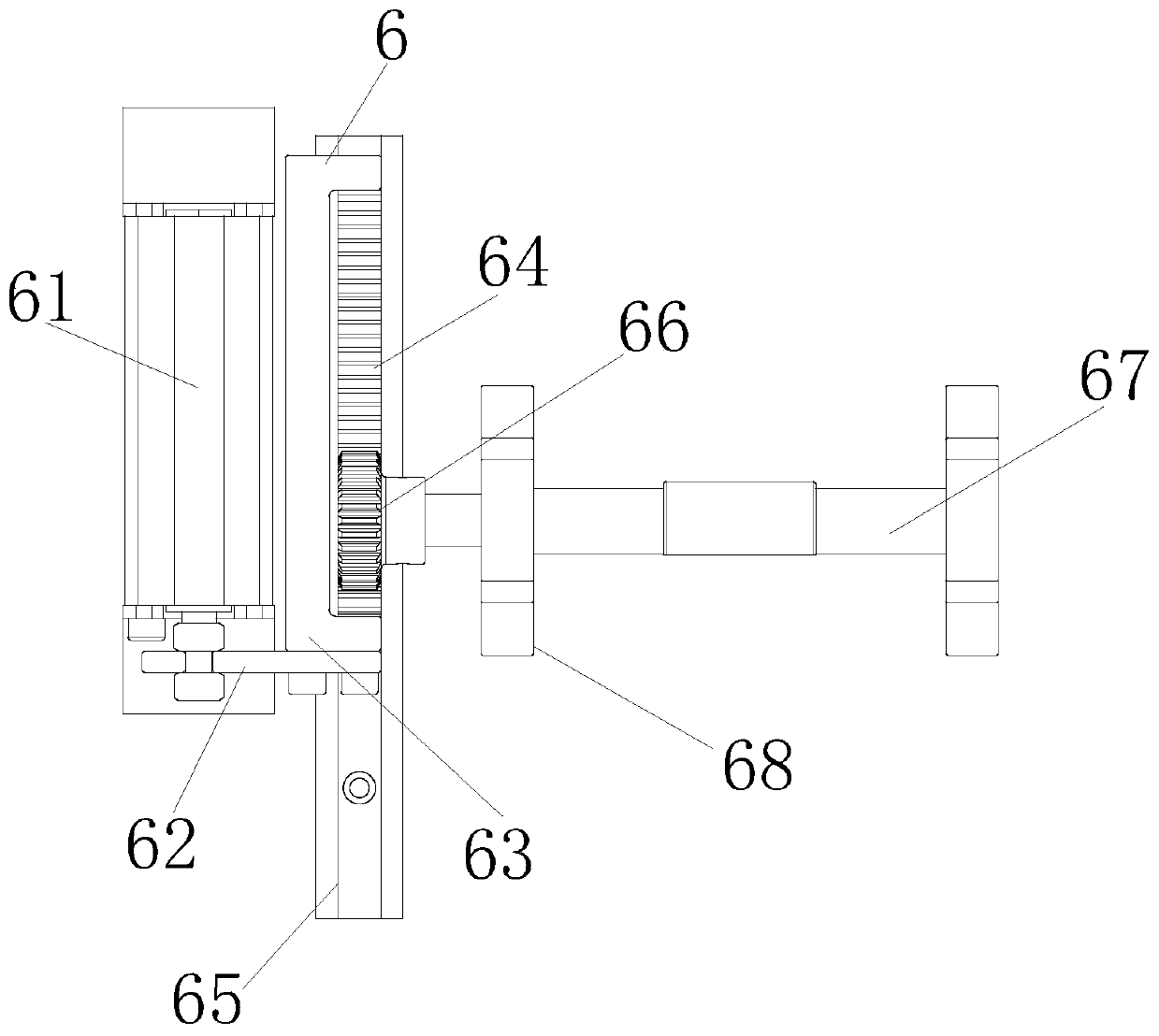

[0028] see figure 1 and figure 2 , the present invention provides an auxiliary fixing device for model making through improvement, including a bottom plate 1, a fixing seat 7, a knob 8, a screw rod 9, a splint 10, a slide bar 11, a tilting mechanism 6 and a buffer mechanism 12, The bottom plate 1 and the bottom of the protective cover 2 are fixed together, the top of the protective cover 2 is provided with a control panel 3, the top of the control panel 3 is equipped with a button 4, the rear end of the protective cover 2 is fixed with a power lead 5, and the screw rod 9 is connected to the inner wall of the fixing seat 7 Flexible connection, the tilting and turning mechanism 6 is installed and fixed on the inner side of the protective cover 2, and the tilting and turning mechanism 6 is tightly fixed to the bottom of the fixing seat 7, the buffer mechanism 12 is fixedly connected to the front end of the fixing seat 7, the screw rod 9 is fixedly connected to the left end of th...

Embodiment 2

[0032] The present invention provides an auxiliary fixing device for model making through improvement. There are two splints 10 in total, and the splints 10 are symmetrically distributed along the left and right sides of the upper end of the screw rod 9, which is beneficial to clamping the parts. For the function of fixing, the upper end of the screw rod 9 is provided with threads, and the left and right ends of the upper end of the screw rod 9 are symmetrical threads, which is beneficial to drive the two splints 10 to clamp the parts, and the upper end of the knob 8 is provided with strip-shaped anti-skid lines , and the anti-slip lines are equidistantly distributed along the surface of the upper end of the knob 8, which is beneficial to play the role of anti-slip.

[0033] The present invention provides an auxiliary fixing device for model making through improvement, and its working principle is as follows;

[0034] First, before use, the auxiliary fixing device used for mod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com