Multidirectional machining device for machining elevator type mechanical parts

A technology for mechanical parts and elevators, applied in the field of parts processing, can solve the problems of increasing the cost of processing equipment, unable to realize the conversion of drilling positions in linkage, and easy to generate residues, etc., and achieve the effect of rapid adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

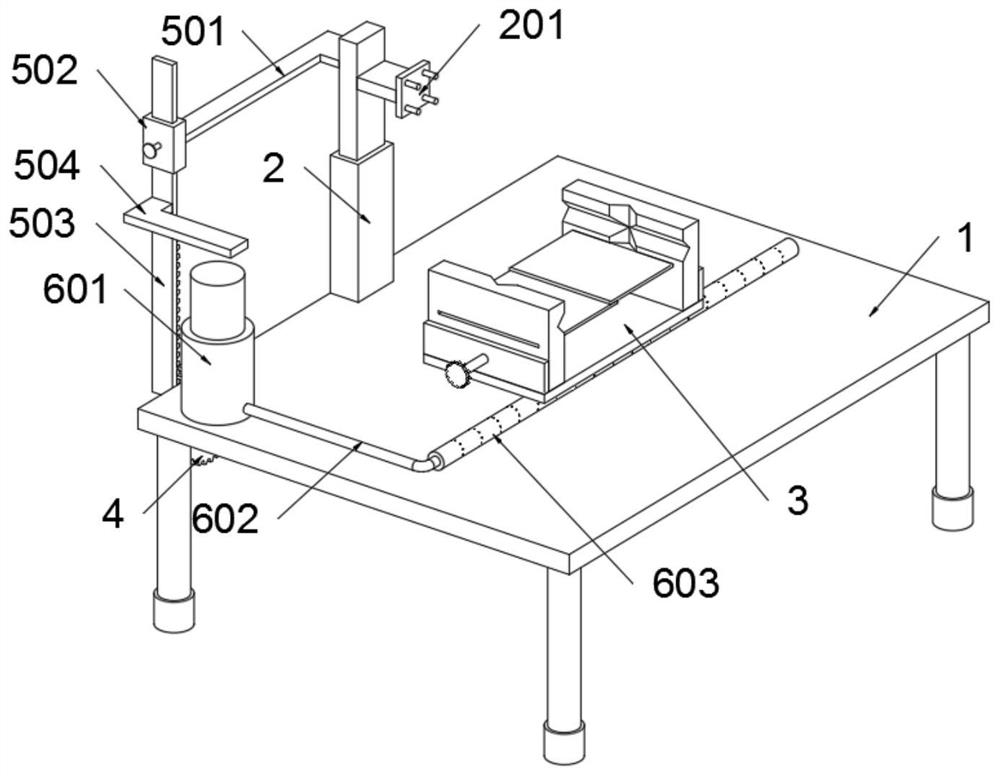

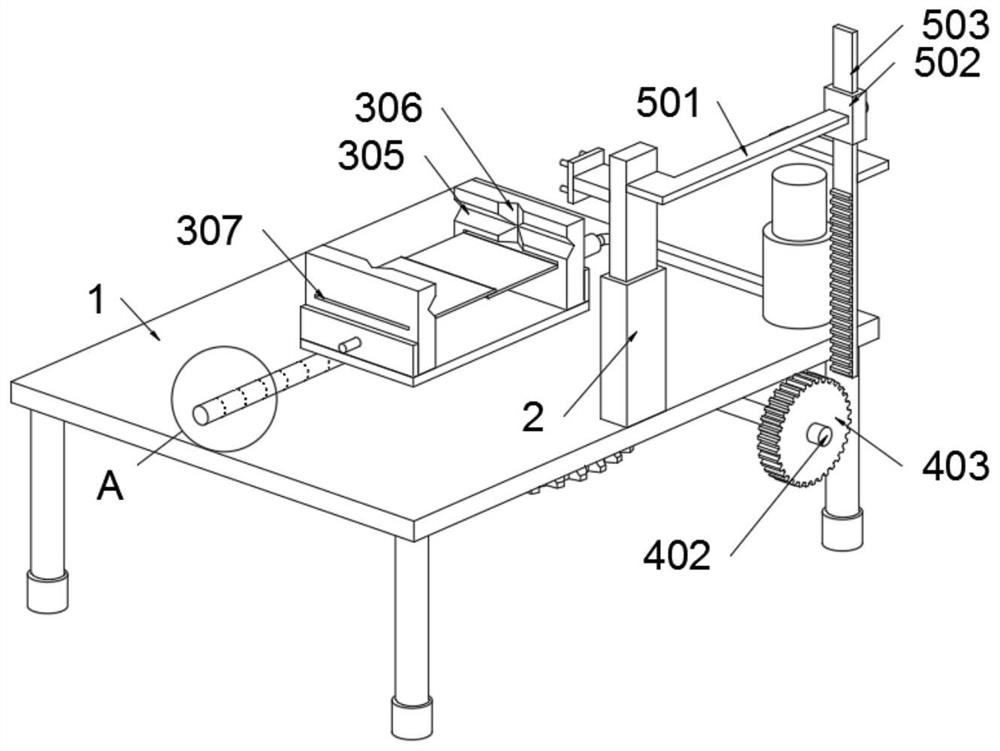

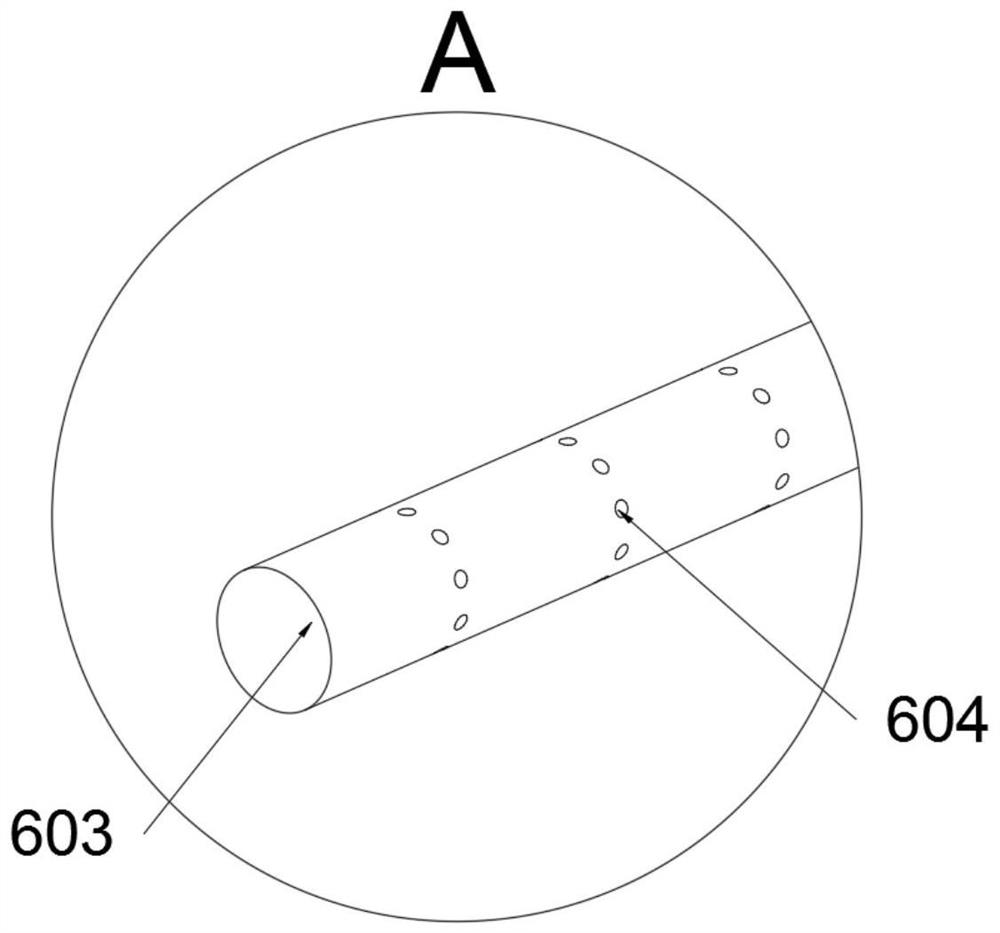

[0032] as attached figure 1 to attach Figure 7 Shown:

[0033]The invention provides a multi-directional processing device for the processing of mechanical parts of elevators and elevators, which includes a table body 1; an adjusting arm 2 is installed on the table body 1, and a clamping structure 3 is installed on the table body 1; An adjustment structure 4 is also installed; a toggle structure 5 is installed on the adjustment arm 2; a cleaning structure 6 is installed on the table body 1; refer to as Image 6 , the clamping structure 3 includes a baffle 307, and there are two baffles 307, and the two baffles 307 are respectively welded on the two clamping blocks 304; the two baffles 307 are arranged in a staggered shape, and the two baffles The plates 307 are all located above the adjustment rod 303, and the two baffles 307 jointly form the protective structure of the adjustment rod 303, thereby preventing the workpiece from contacting the adjustment rod 303 and causing b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com