Wind turbine blade de-icing device and wind turbine

A technology for wind turbines and blades, which is applied to wind turbines, wind turbine control, and wind turbine monitoring, etc., can solve problems such as the inability to protect circuits immediately

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

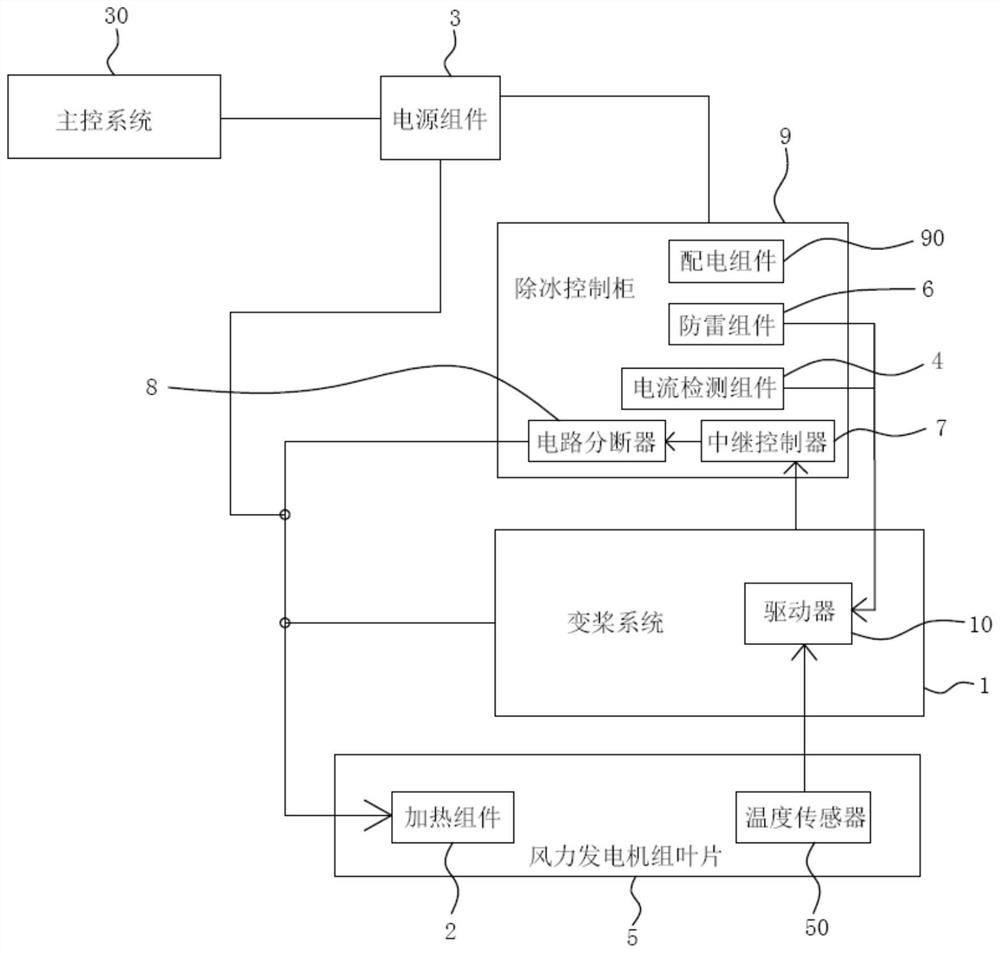

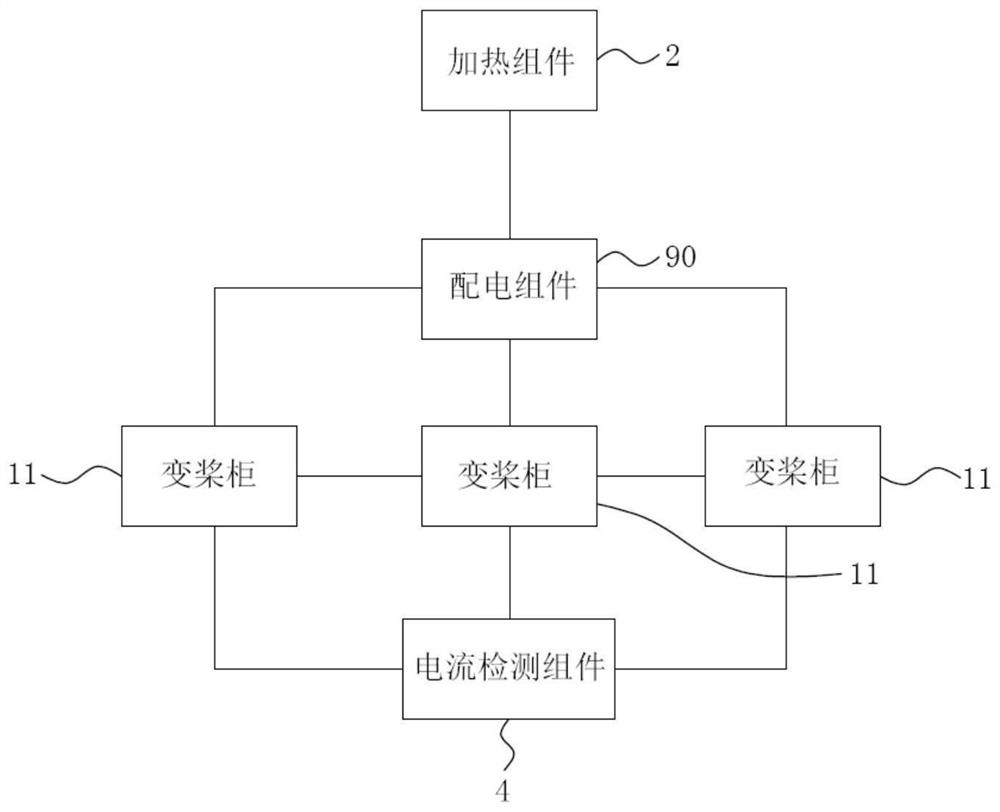

[0037] Such as figure 1 As shown, the wind power generator blade deicing device provided in this embodiment includes a pitch system 1 , a heating assembly 2 , a power supply assembly 3 and a current detection assembly 4 . The pitch system 1 is provided with a driver 10, and the power supply assembly 3, the driver 10 and the heating assembly 2 are connected in sequence. The current detection component 4 is installed on the circuit between the heating component 2 and the power supply component 3, and is connected with the driver 10, and the current detection component 4 is used for detecting the current value. A preset current value is set in the driver 10, and the driver 10 can receive the current value detected by the current detection component 4, and control the power off between the heating component 2 and the power supply component 3 when the current value is greater than the preset current value. The heating assembly 2 is connected to the blade 5 of the wind power genera...

Embodiment 2

[0074] The wind power generator set provided in this embodiment includes blades and the blade deicing device of the wind power generator set in Embodiment 1, and the heating assembly in the blade deicing device of the wind power generator set is connected to the blades.

[0075] The wind power generating set provided in this embodiment includes the wind power generating set blade deicing device in Embodiment 1, so the wind generating set provided in this embodiment and the wind generating set blade deicing device in Embodiment 1 can solve the same technical problem , to achieve the same technical effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com