Systems and methods for improving vehicle engine stability

An engine and stability technology, applied in engine control, engine components, machine/engine, etc., to solve problems such as increasing decompression time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

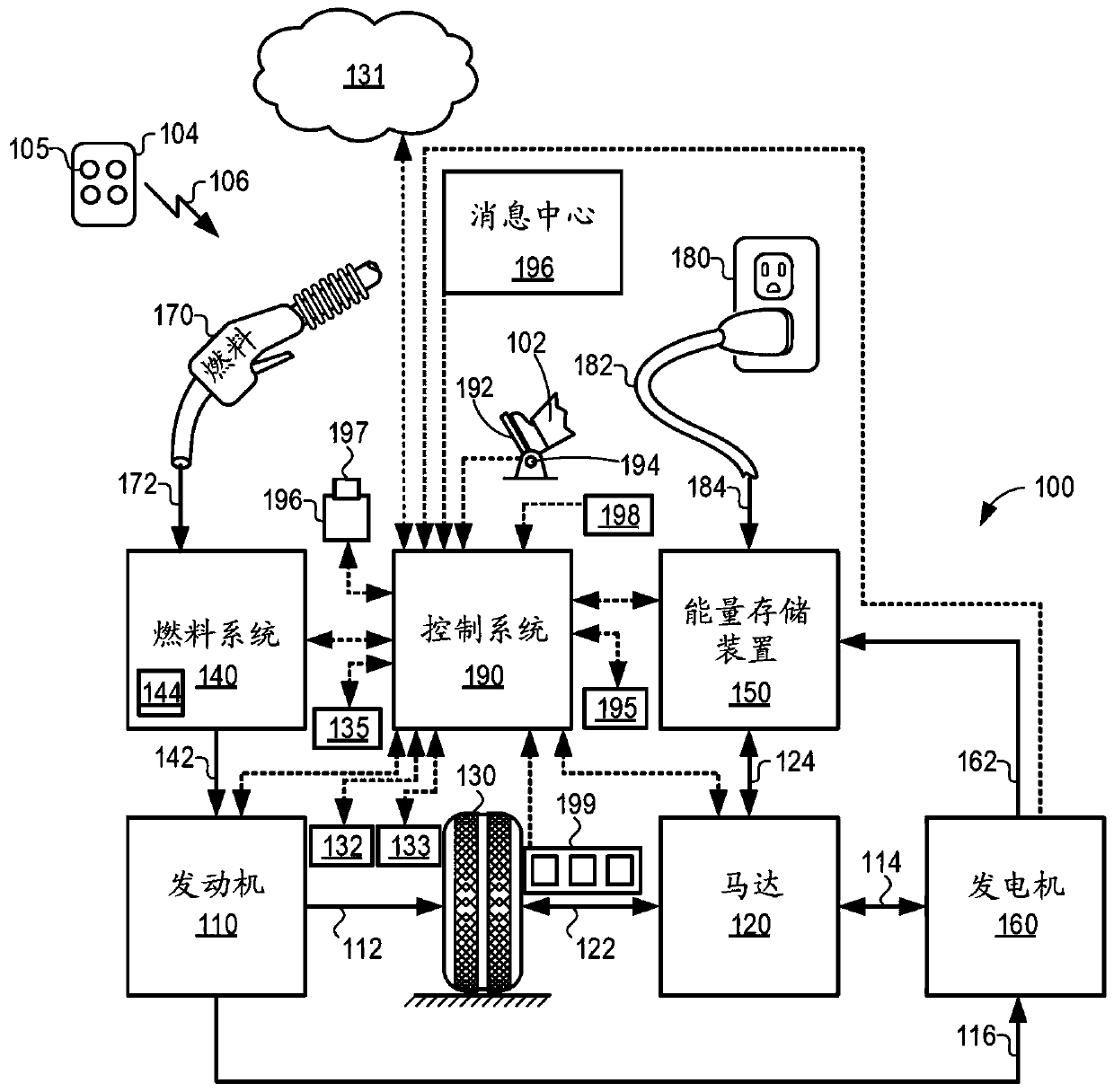

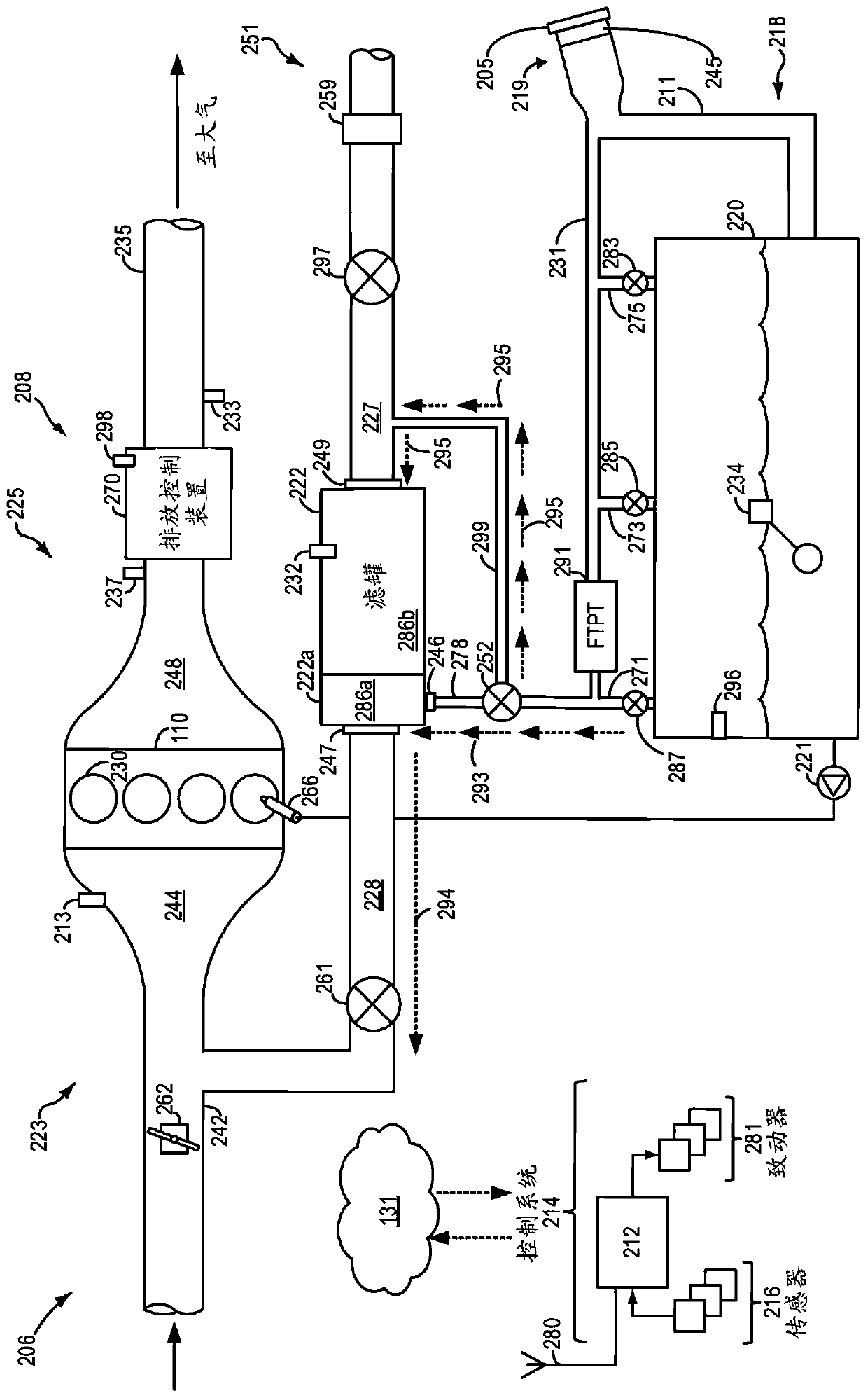

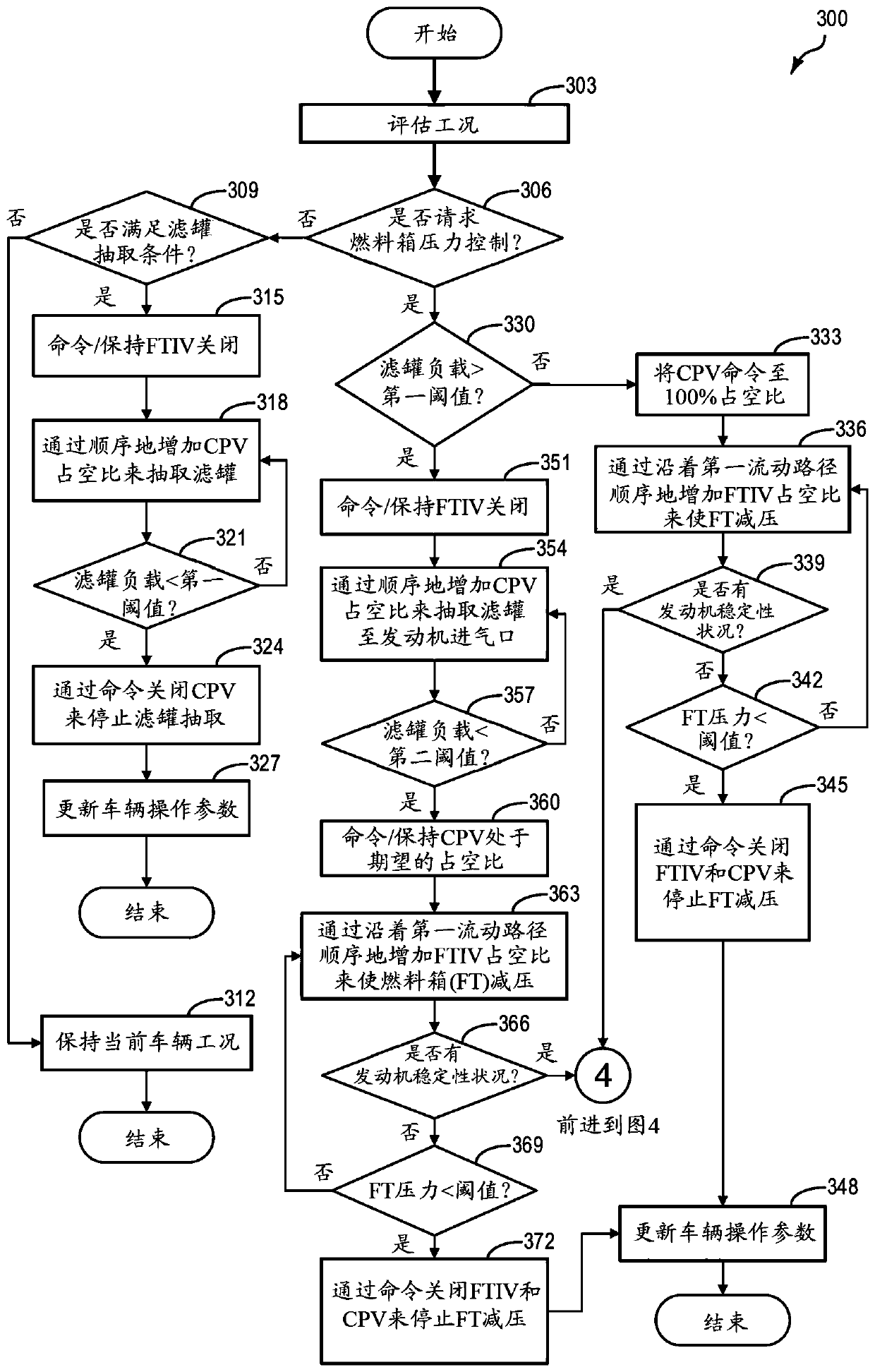

[0014] The following description relates to systems and methods for performing tank pressure control operations (also referred to herein as tank pressure control or TPC operations). In particular, such systems and methods relate to conducting TPC operations that can continue without having to abort. More specifically, for such TPC operation, fuel tank vapors may be directed along a first flow path that includes vapors being directed through a portion of the fuel vapor canister (eg, buffer zone) and then to the engine, provided that is a condition that does not indicate degraded engine stability. However, in response to such indications of degraded engine stability, the fuel vapors may then be redirected along a second flow path that includes the vapors being directed through the entire fuel vapor filter before being directed to the engine. Can. Such systems and methods are useful for hybrid electric vehicles with limited engine run time, such as figure 1 The depicted hybri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com