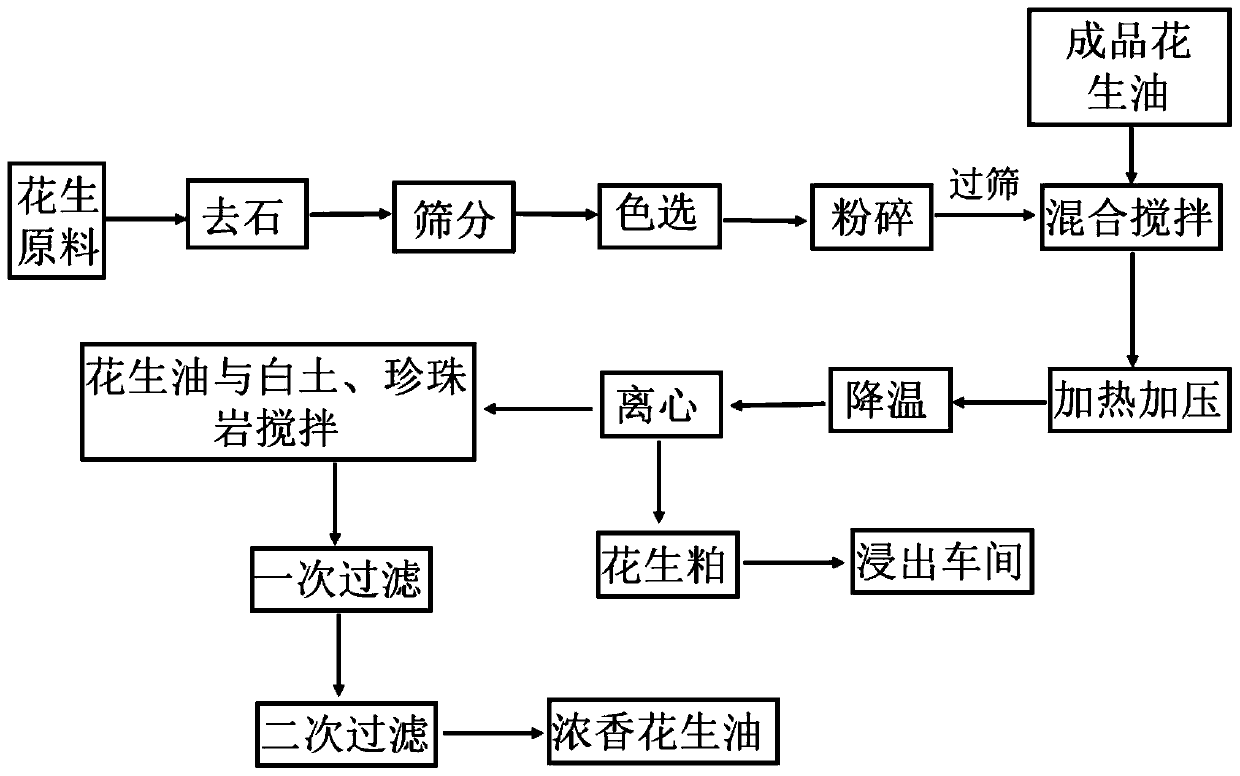

Production process of fragrant peanut oil

A production process and technology of peanut oil, which are applied in the directions of fat oil/fat production, fat production, edible oil/fat, etc., can solve the problems of complex process flow, high production cost, cumbersome preparation steps, etc., and achieve safe and simple preparation process flow. The effect of rich oil flavor and simple processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

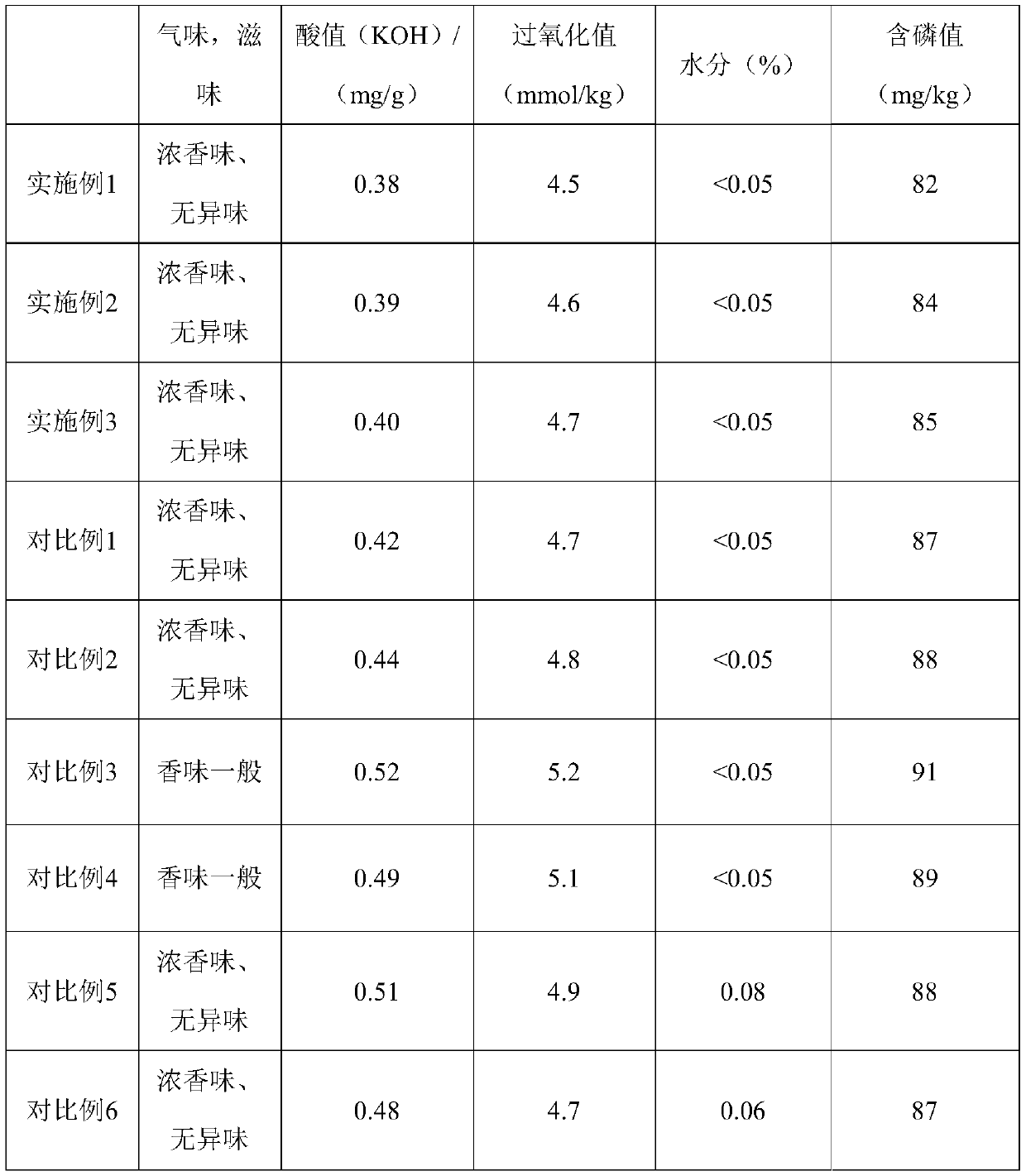

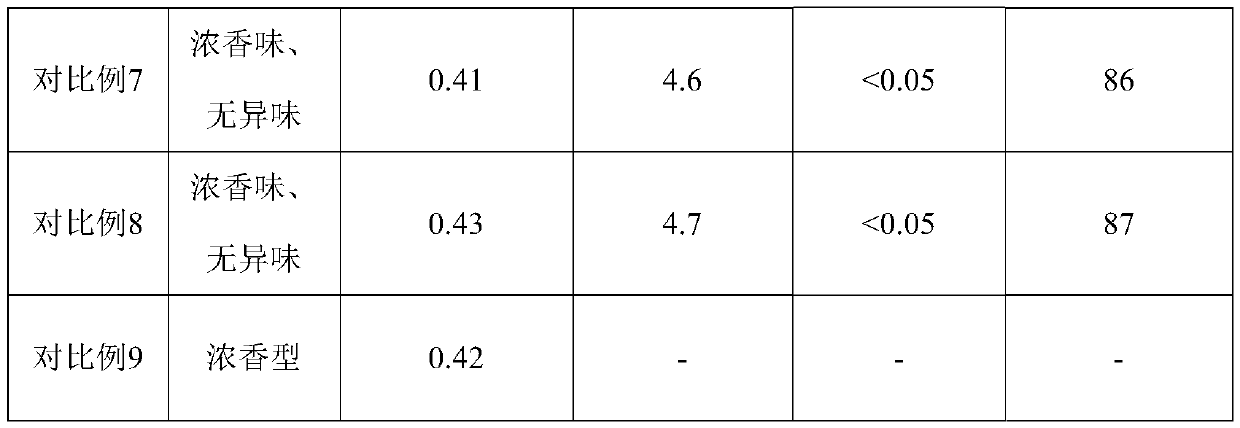

[0034] A production process of fragrant peanut oil, comprising the following steps:

[0035] (1) Peanut raw materials are destoned, sieved, and color-selected twice to remove impurities so that the impurity content is lower than 0.2%, then remove the peanut coat, crush the peanut kernels until the particle size is less than 2.0mm, and pass through a 200-mesh sieve. get crushed peanut kernels;

[0036] (2) Add the crushed peanut kernels obtained in step (1) to the first-grade peanut oil, the weight ratio of the first-grade peanut oil to peanut kernels is 5:1, mix and stir at 70°C for 1.5h, and then heat at 105°C 1.5h, the pressure is 0.2Mpa, then lower the temperature, first lower the temperature to 65°C, keep it warm for 1h, and then lower it to room temperature. min, the time is 1.5h; then carry out high-speed centrifugation, the centrifugal speed is 4500r / min, and the time is 20min, to obtain peanut oil;

[0037] (3) The peanut oil obtained in step (2) is added to the clay...

Embodiment 2

[0039] A production process of fragrant peanut oil, comprising the following steps:

[0040] (1) Peanut raw materials are destoned, sieved, and color-selected twice to remove impurities so that the impurity content is lower than 0.2%, then remove the peanut coat, crush the peanut kernels until the particle size is less than 2.0mm, and pass through a 200-mesh sieve. get crushed peanut kernels;

[0041] (2) Add the crushed peanut kernels obtained in step (1) to the first-grade peanut oil, the weight ratio of the first-grade peanut oil to peanut kernels is 3:1, mix and stir at 60°C for 1h, and then heat at 95°C for 2h , the pressure is 0.1Mpa, the temperature is lowered to 60°C first, kept for 0.5h, and then lowered to room temperature. 1h; then carry out high-speed centrifugation, the centrifugal speed is 3000r / min, and the time is 10min, to obtain peanut oil;

[0042](3) The peanut oil that step (2) obtains is added white clay perlite, wherein white clay accounts for 0.2% whi...

Embodiment 3

[0044] A production process of fragrant peanut oil, comprising the following steps:

[0045] (1) Peanut raw materials are destoned, sieved, and color-selected twice to remove impurities so that the impurity content is lower than 0.2%, then remove the peanut coat, crush the peanut kernels until the particle size is less than 2.0mm, and pass through a 200-mesh sieve. get crushed peanut kernels;

[0046] (2) Add the crushed peanut kernels obtained in step (1) to the first-grade peanut oil, the weight ratio of the first-grade peanut oil to peanut kernels is 8:1, mix and stir at 80°C for 2h, and then heat at 110°C for 1h , the pressure is 0.3Mpa, the temperature is lowered to 70°C first, kept for 1h, and then lowered to room temperature, the pressure remains unchanged when the temperature is lowered, and then centrifuged, first at a low speed, the speed of centrifugation is 1200r / min, and the time is 2h Carry out high-speed centrifugation again, the speed of centrifugation is 6000...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| peroxide value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com