A kind of biocoal and its preparation system and preparation method

A preparation system, coal technology, applied in the direction of biofuel, waste fuel, fuel, etc., can solve the problems of easy moisture accumulation, difficult combustion, insufficient combustion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

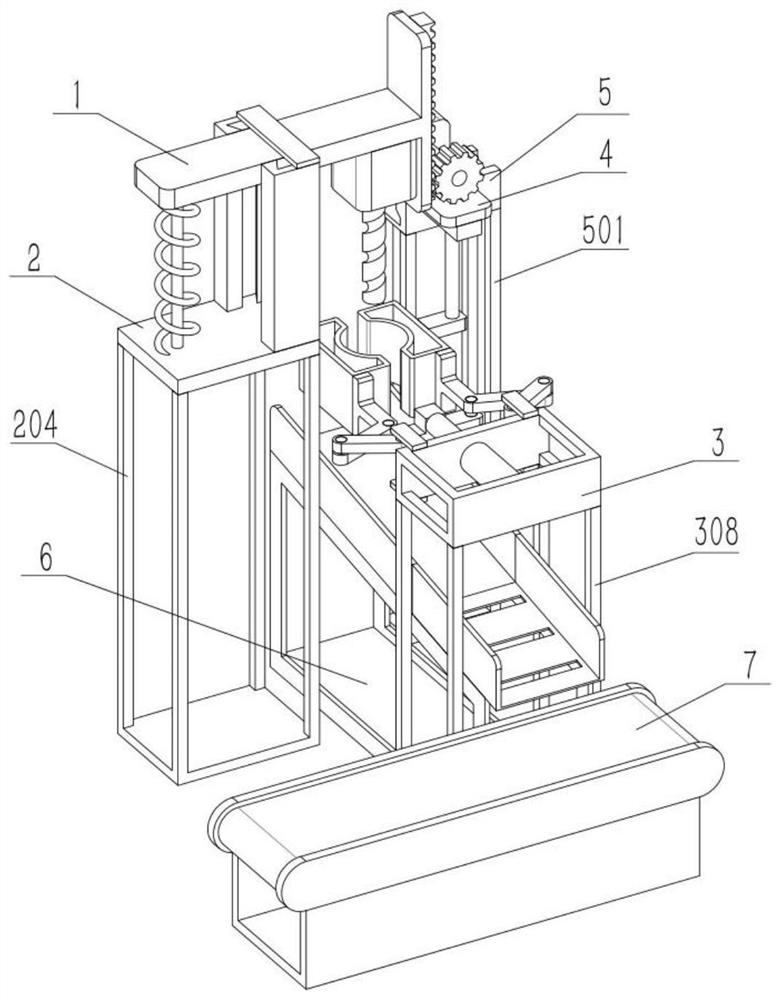

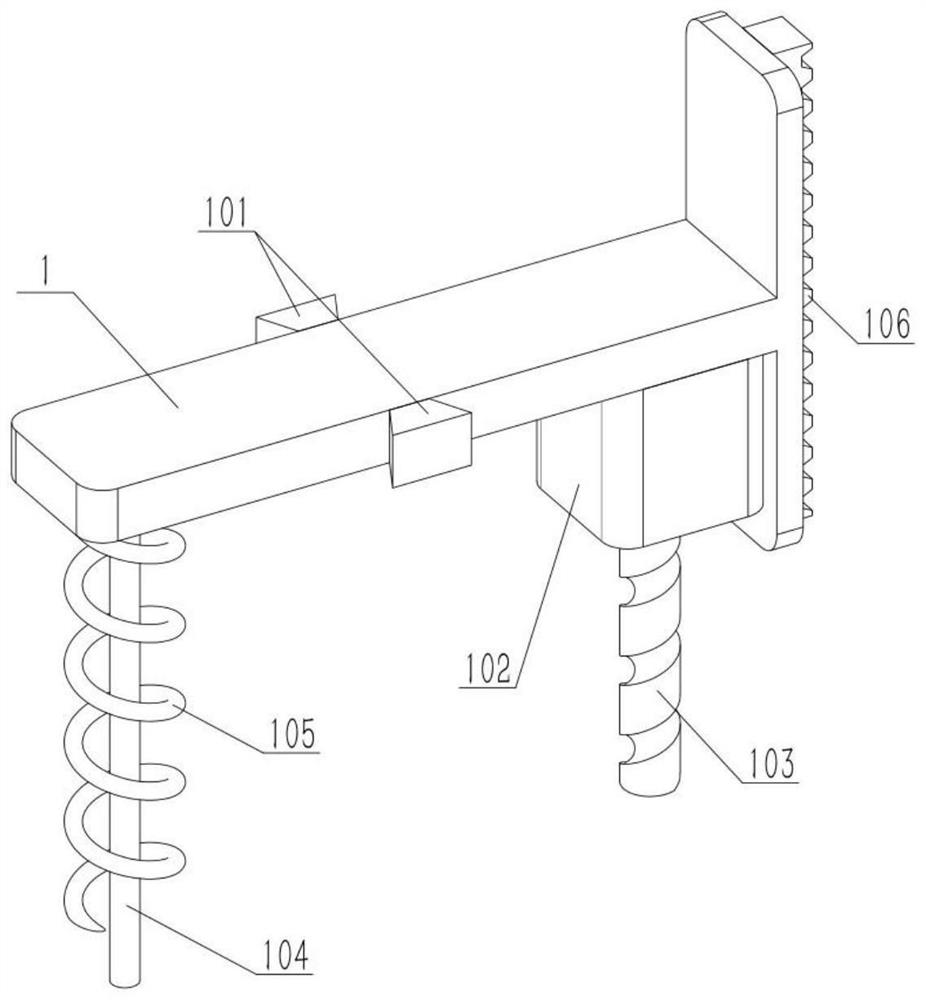

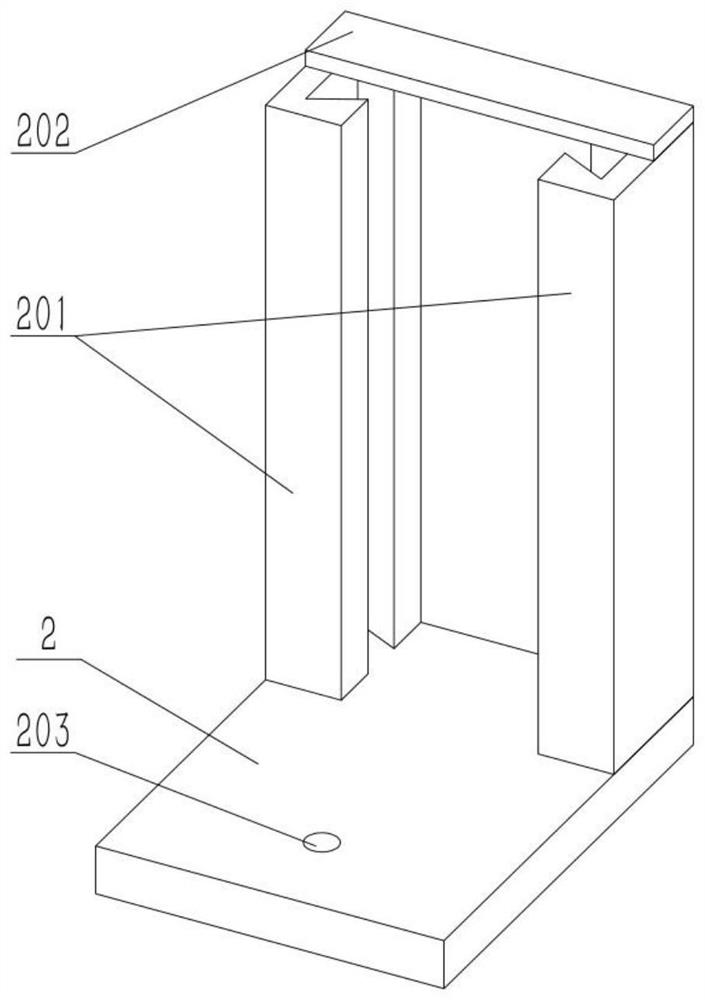

[0030] like Figure 1-7 As shown, a bio-coal preparation system includes double-end frame 1, guide block I101, motor I102, drill bit 103, rack 106, flat seat I2, grooved guide rail I201, flat seat frame 204, flat seat II4, motor II401 and gear 402, the front and rear ends of the double-end frame 1 are respectively fixed with a guide block I101, the motor I102 is fixed at the lower end of the double-end frame 1, the output shaft of the motor I102 is fixed with the drill bit 103, and the rack 106 is fixed Connected to the right end of the double-end frame 1; two mirror-symmetrically arranged grooved guide rails I201 are fixed on the flat seat I2, and the two guide blocks I101 are respectively slidably connected in the two grooved guide rails I201; the upper end of the flat seat II4 is fixed The motor II 401, the output shaft of the motor II 401 is fixedly connected with the gear 402, the gear 402 is meshed with the rack 106 for transmission, and the flat seat II 4 is installed o...

specific Embodiment approach 2

[0031] like Figure 1-7 As shown, the bio-coal preparation system also includes a fixed base 3, a fixed base frame 308, an electric telescopic rod 301, a shaft I 302, a connecting rod I 303, a V-shaped arm 304 and a carbon fixing part 305, and the fixed base 3 is fixed on On the fixed seat frame 308, the electric telescopic rod 301 is fixedly connected to the fixed seat 3, the movable end of the electric telescopic rod 301 passes through the fixed seat 3, and the left and right sides of the front end of the fixed seat 3 are respectively fixed with a shaft I 302, two shafts One end of a connecting rod I303 is respectively hingedly connected to I302, and the other ends of two connecting rods I303 are respectively hingedly connected to one end of a V-shaped arm 304. On both sides, the other ends of the two V-shaped arms 304 are fixedly connected to a carbon fixing part 305 respectively, and the movable end of the electric telescopic rod 301 is stretched and retracted to drive the...

specific Embodiment approach 3

[0032] like Figure 1-7As shown, the biocoal preparation system also includes a shaft seat 306, shaft II 307, transmission frame 403, guide block II 404, grooved guide rail II 5, and guide rail frame 501. The shaft seat 306 is fixed to the carbon-fixing part on the right 305, the shaft II 307 is fixed on the upper end of the shaft seat 306, the shaft II 307 is inserted and slid on the rear side of the transmission frame 403, the transmission frame 403 is fixed on the lower end of the flat seat II4, and the guide block II 404 is fixed on the lower end of the transmission frame 403. On the front side, the guide block II404 is slidably connected in the grooved guide rail II5 instead of the flat seat II4 and installed on the frame, and the lower end of the guide rail II5 is fixedly connected to the guide rail frame 501; after the two carbon fixing parts 305 are closed, the shaft II307 has been moved to the left The transmission frame 403 makes the gear 402 mesh with the rack 106 f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com