Method for synthesizing cobalt-doped ferronickel mesh nanosheet array efficient bifunctional electrocatalyst and application

A nanosheet array, electrocatalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the constraints of large-scale synthesis and application, complex synthesis process , single catalytic performance and other problems, to achieve high-efficiency dual-function catalysis, solve the effect of single catalytic performance, simple and easy to operate process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

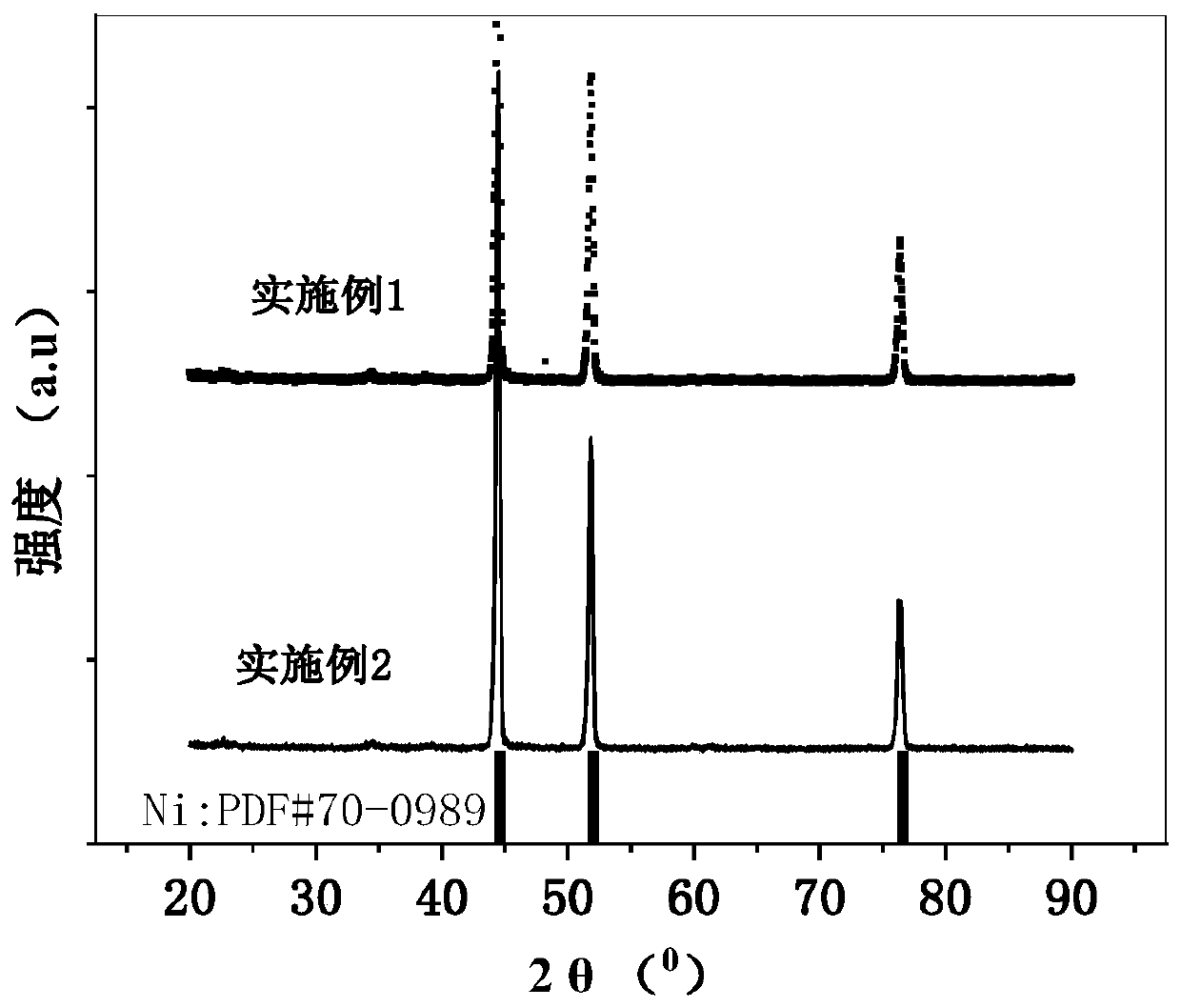

Embodiment 1

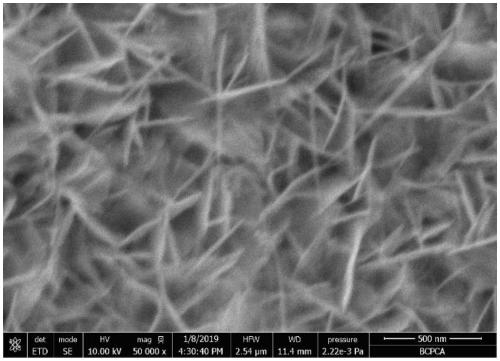

[0040] Embodiment 1: A method for synthesizing cobalt-doped nickel-iron mesh nanosheet arrays with high-efficiency bifunctional electrocatalysts is completed in the following steps:

[0041] (1) Pretreatment of nickel foam:

[0042] Immerse the commercial foamed nickel in 0.5M dilute hydrochloric acid for 15 minutes, and after taking it out, first use absolute ethanol to ultrasonically clean it for 10 minutes, and then rinse it with deionized water for 3 times to obtain foamed nickel from which impurities have been removed;

[0043] The thickness 1.2mm of the commercial nickel foam described in step (1), aperture is 200 μ m;

[0044] The length of the commercial nickel foam described in the step (1) is 2cm, and the width is 3cm;

[0045] (2) Preparation of nickel-iron salt solution A:

[0046] Dissolve the iron salt, nickel salt and urea into deionized water, and magnetically stir for 5 minutes to obtain nickel-iron salt solution A;

[0047] In the nickel-iron salt solution...

Embodiment 2

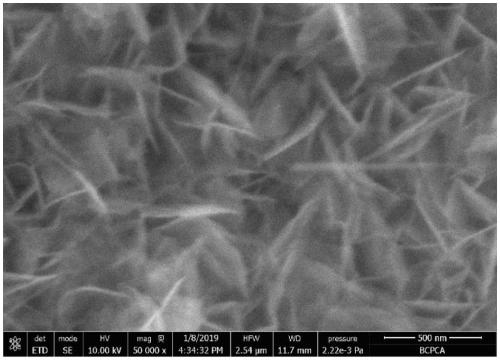

[0060] Embodiment 2: A method for synthesizing cobalt-doped nickel-iron mesh nanosheet arrays with high-efficiency bifunctional electrocatalysts is completed in the following steps:

[0061] (1) Pretreatment of nickel foam:

[0062] Immerse the commercial foamed nickel in 2M dilute hydrochloric acid for 20 minutes, after taking it out, first use absolute ethanol to ultrasonically clean it for 15 minutes, and then rinse it with deionized water for 5 times to obtain the foamed nickel from which impurities have been removed;

[0063] The thickness 1.7mm of the commercial nickel foam described in step (1), aperture is 400 μ m;

[0064] The length of the commercial nickel foam described in the step (1) is 2cm, and the width is 4cm;

[0065] (2) Preparation of nickel-iron salt solution A:

[0066] Dissolve iron salt, nickel salt and urea in deionized water, and stir magnetically for 10 minutes to obtain nickel-iron salt solution A;

[0067] In the nickel-iron salt solution A desc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com