Wheat flour composition

A technology of wheat flour and composition, which is applied in the direction of baking mixture, food science, dough/premix, etc., can solve the problems such as no one is clear, and achieve the effect of improving quality and performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

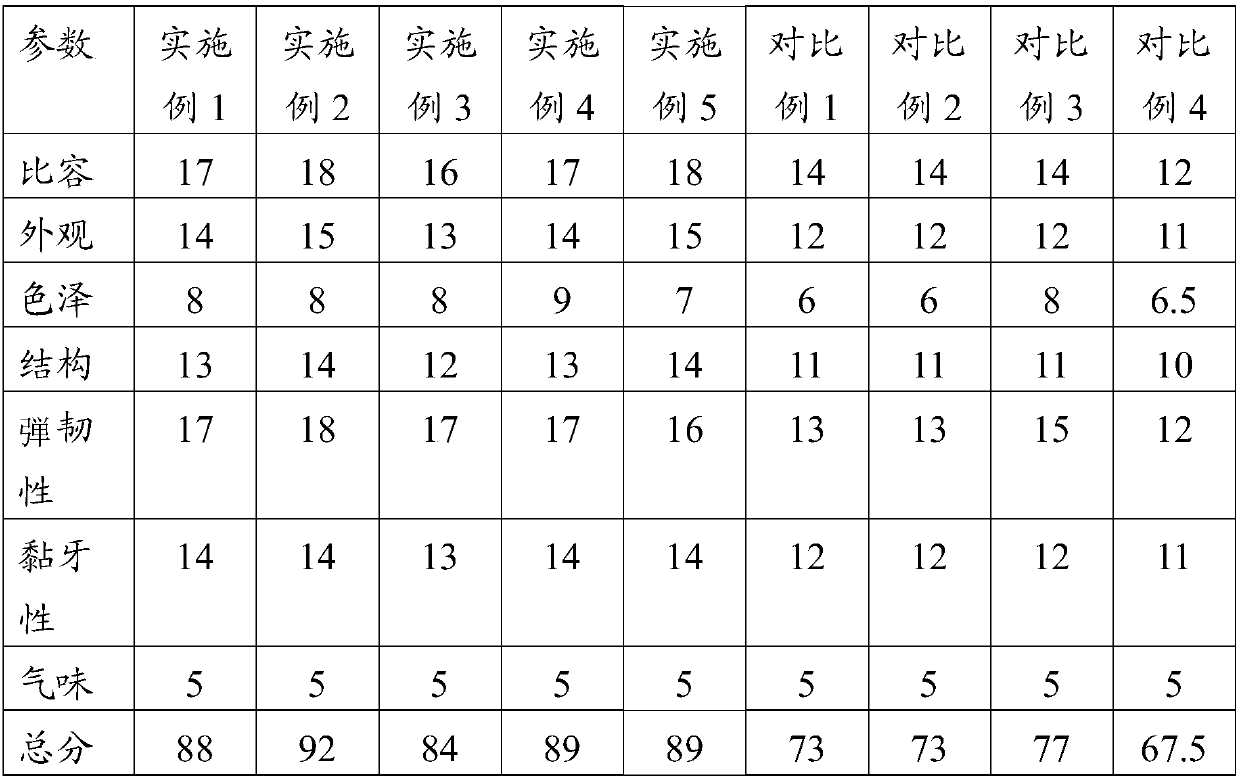

Examples

Embodiment 1

[0070] The preparation method of the material under the 45 micron sieve: Place 160 μm sieve, 125 μm sieve, 100 μm sieve, 63 μm sieve, 45 μm sieve on the Buhler MLUA test sieve from top to bottom, put 400g flour on the top layer On the 160μm flour sieve, sieve at 260rpm for 10min, and take the material under the 45μm sieve.

[0071] The preparation method of the material between the 45-63 micron sieves: Place 160 μm sieves, 125 μm sieves, 100 μm sieves, 63 μm sieves, and 45 μm sieves on the Buhler MLUA test sieve from top to bottom, and put 400g of flour on the On the top 160 μm screen, sieve at 260 rpm for 10 minutes, and take the materials between the 45 μm and 63 μm screens.

[0072] Preparation method of materials between 63-100 micron sieves: Place 160 μm sieves, 125 μm sieves, 100 μm sieves, 63 μm sieves, 45 μm sieves on the Buhler MLUA test sieve from top to bottom, put 400g flour on On the topmost 160 μm screen, sieve at 260 rpm for 10 minutes, and take the materials b...

Embodiment 2

[0078] The particle size distribution of the material obtained after mixing the 45-63 micron sieve material prepared in Example 1 and the 63-100 micron sieve material in a ratio (mass ratio) of 4:96 is as follows:

[0079] Particle size range volume percentage 0-2um,% 0.1 2-40um,% 10.7 40-100um, % 61.6 100-200um, % 27.6

[0080] After testing, the GPI of the flour obtained in Example 2 is 70.3%, and the bran star content is 4.4%.

Embodiment 3

[0082] The particle size distribution of the material obtained after mixing the material under the 45 micron sieve prepared in Example 1 and the material between the 63-100 micron sieve in a ratio (mass ratio) of 7:93 is as follows:

[0083] Particle size range volume percentage 0-2um,% 0.3 2-40um,% 14.5 40-100um, % 58.5 100-200um, % 26.7

[0084] After testing, the GPI of the flour obtained in Example 3 is 69.5%, and the bran star content is 4.4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com