Machine head of cookie blank forming machine

A molding machine and cookie technology, applied in dough molding and cutting equipment, dough extruder, food science, etc., can solve the problems of cookie dough thickness and size error, raw materials are not exactly the same, high replacement cost, etc., to achieve Solve the effect that cannot be replaced separately

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

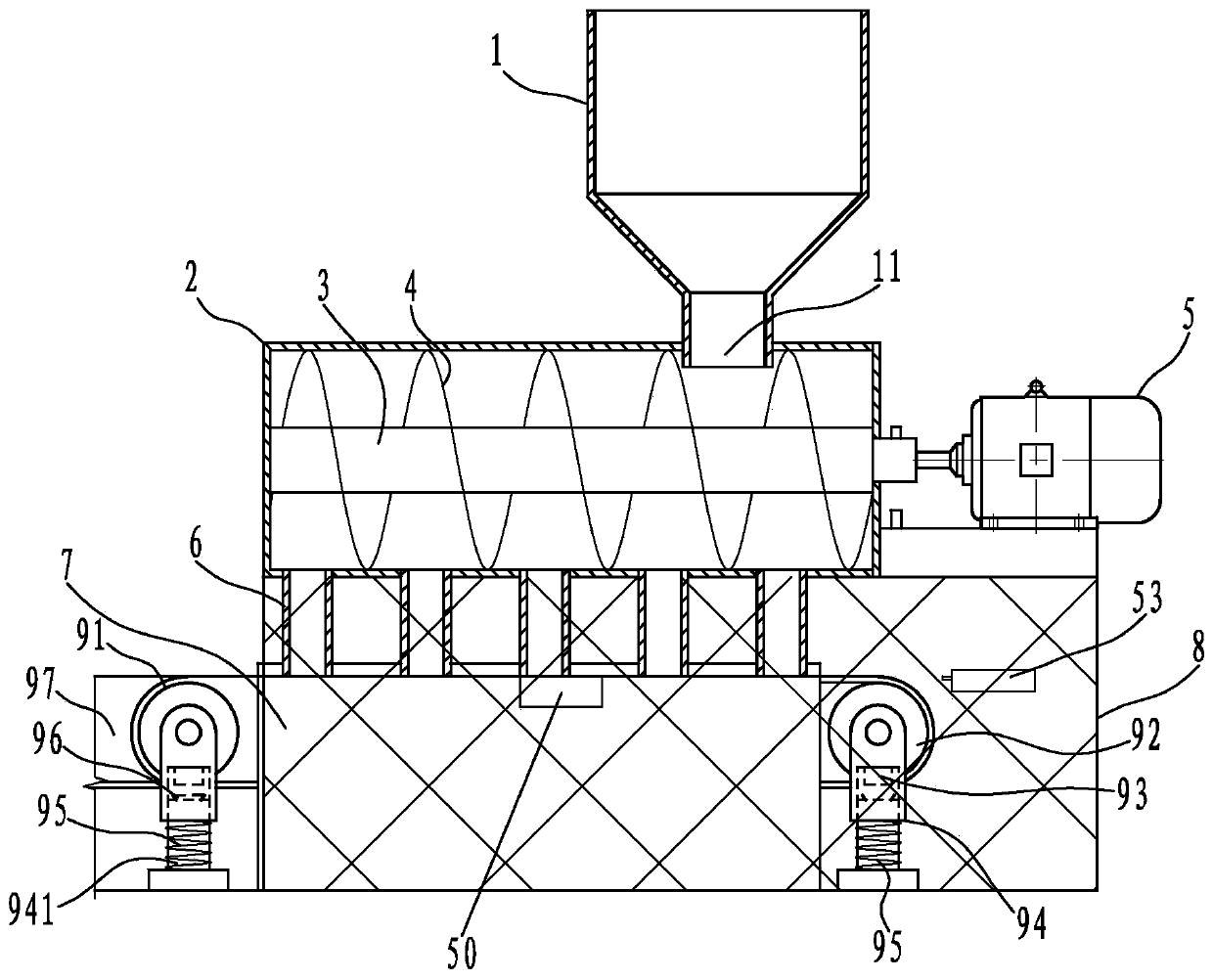

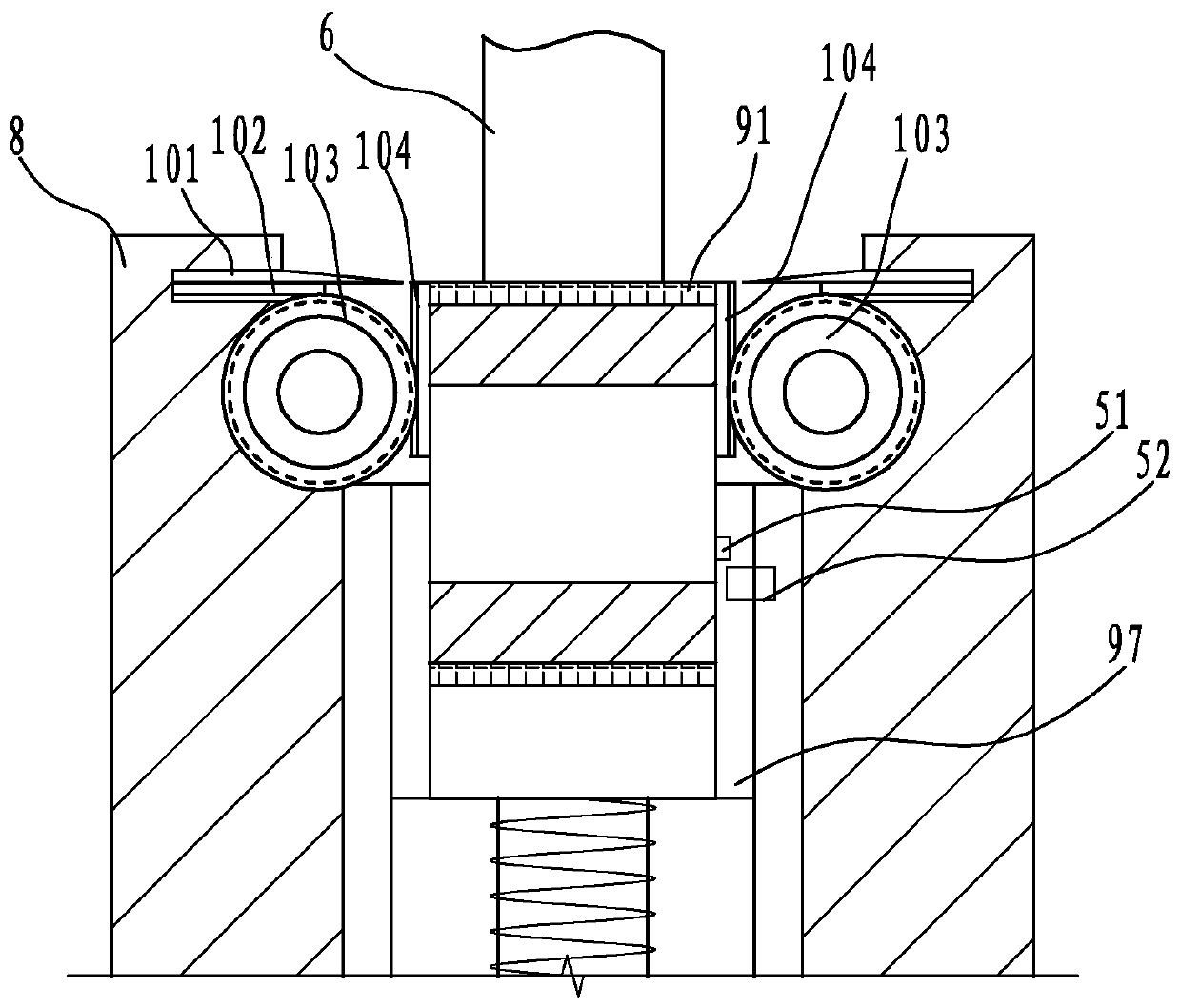

[0017] Such as figure 1 and figure 2 As shown, the head of a cookie dough forming machine disclosed by the present invention includes a body 8 on which a hopper 1, a screw extruding mechanism and a continuous forming mechanism are fixedly installed sequentially from top to bottom. The screw extrusion mechanism includes a horizontally installed extrusion drum 2 , a helical blade 4 arranged axially along the extrusion drum 2 , and a stepping motor 5 for driving the helical blade 4 . The spiral blade 4 is fixedly installed on the rotating shaft 3, one end of the rotating shaft 3 is connected to the left side of the extrusion drum 2 in rotation, the other end of the rotating shaft 3 runs through the right end baffle of the extrusion drum 2, and is connected with the output shaft of the stepping motor 5. The shaft is fixed. The screw blade 4 is driven to rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com