Rotary electric machine

A technology of rotating electrical machines and rotors, applied in the field of rotating electrical machines, which can solve the problems that the cooling medium is not easy to scatter and cannot cool the coils, etc., and achieves the effect of good efficiency and improved rotation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0029]

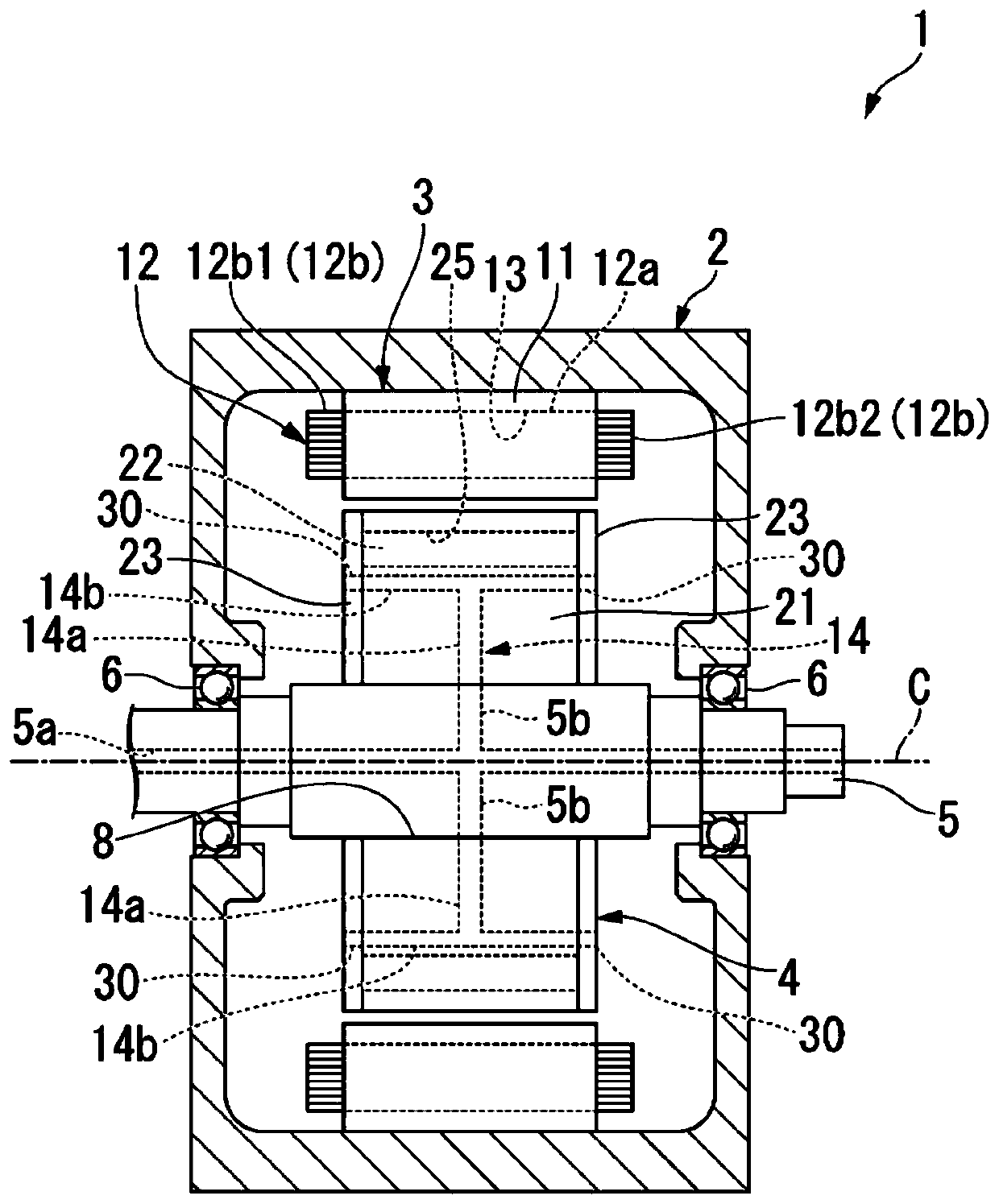

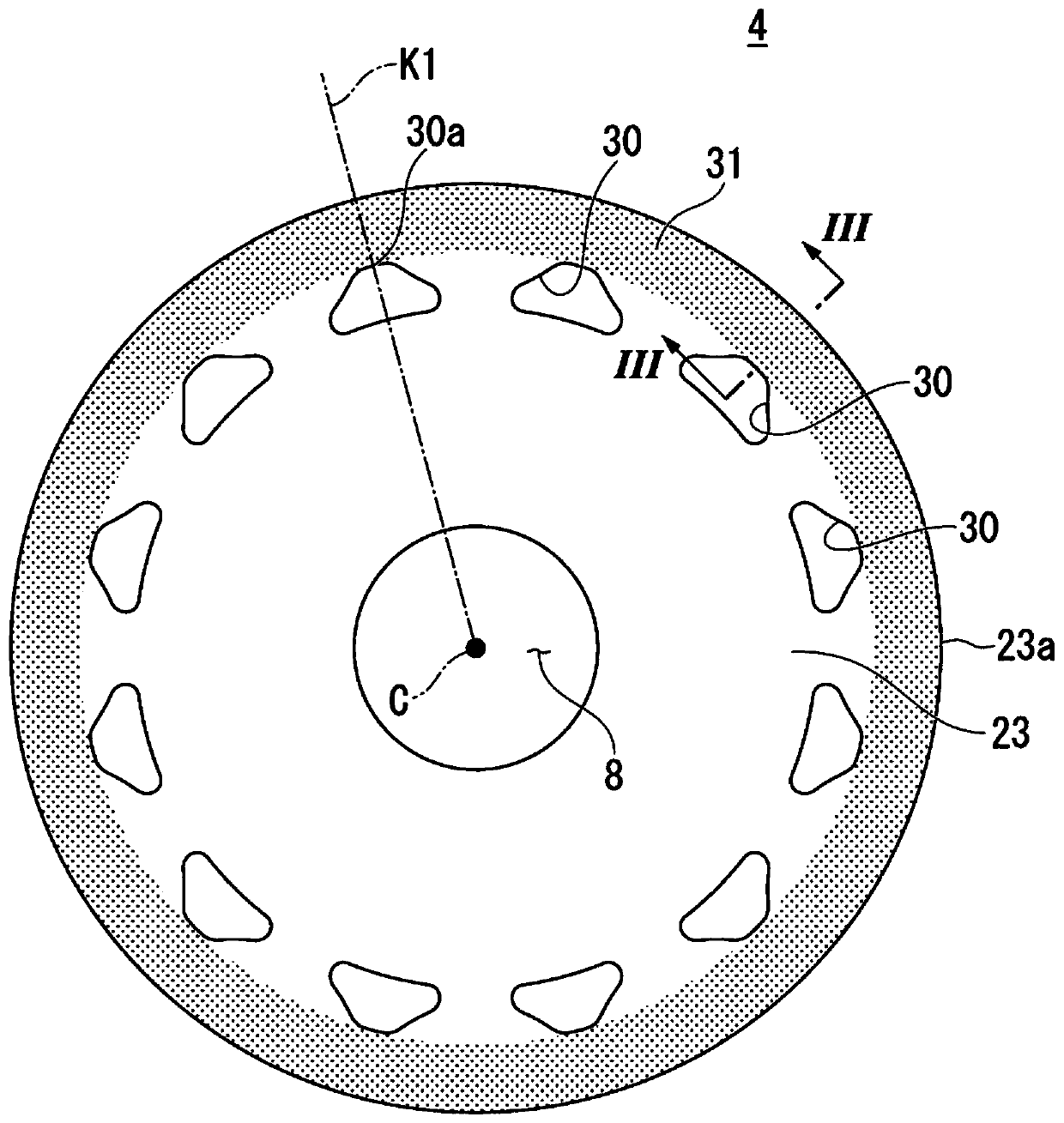

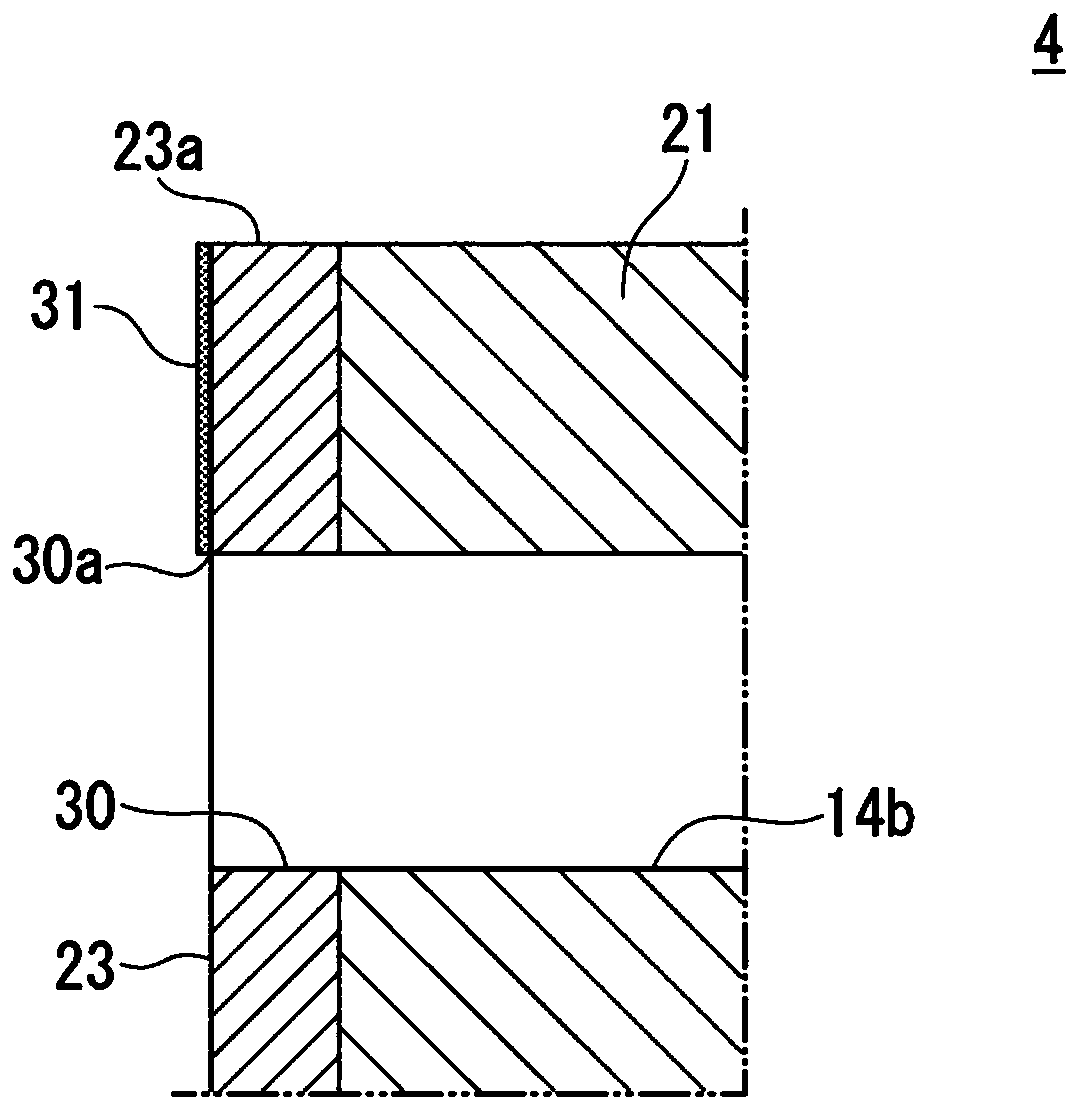

[0030] figure 1 It is a schematic configuration diagram showing the overall configuration of the rotating electrical machine 1 according to the first embodiment. figure 1 It is a figure including the cross section cut with the imaginary plane containing the axis C.

[0031] Such as figure 1 As shown, the rotating electric machine 1 includes a housing 2, a stator 3, a rotor 4, an output shaft 5, and a cooling medium supply mechanism (not shown).

[0032] The case 2 is formed in a cylindrical box shape for accommodating the stator 3 and the rotor 4 . A cooling medium (not shown) is accommodated in the casing 2 . A part of the stator 3 is arranged in a state immersed in the cooling medium in the case 2 . For example, ATF (Automatic Transmission Fluid), which is hydraulic oil used for transmission lubrication, power transmission, and the like, is used as the cooling medium.

[0033] The output shaft 5 is rotatably supported by the housing 2 . exist figure 1 In , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com