Anti-shake system for miniature camera shooting

A micro-camera and anti-shake technology, which is applied to the focusing device of the projector, the focusing device of the camera, and optics, etc., can solve the problems of blurred images, complicated procedures, and high costs, and achieve rapid increase in production capacity and rapid and accurate production , cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

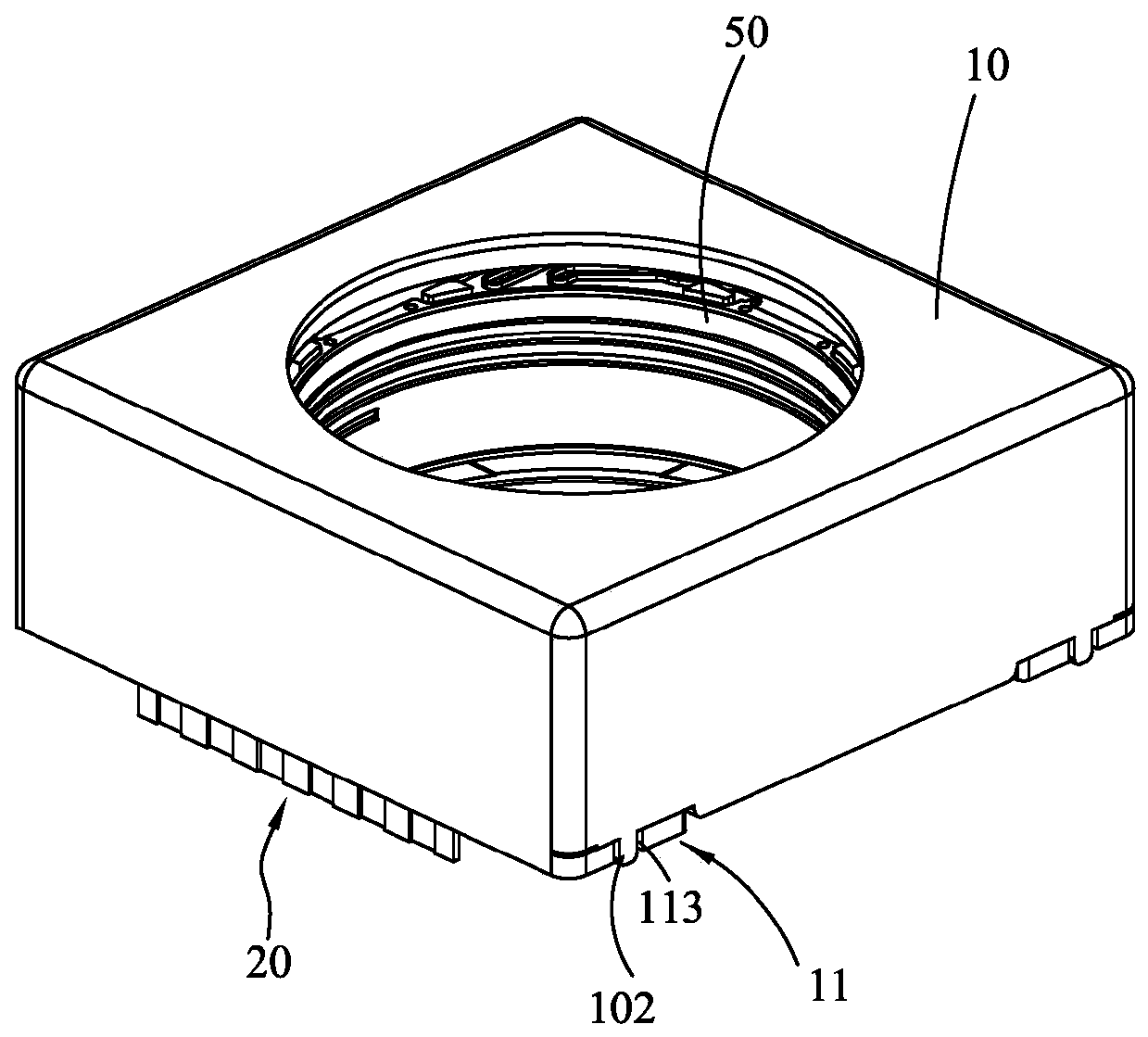

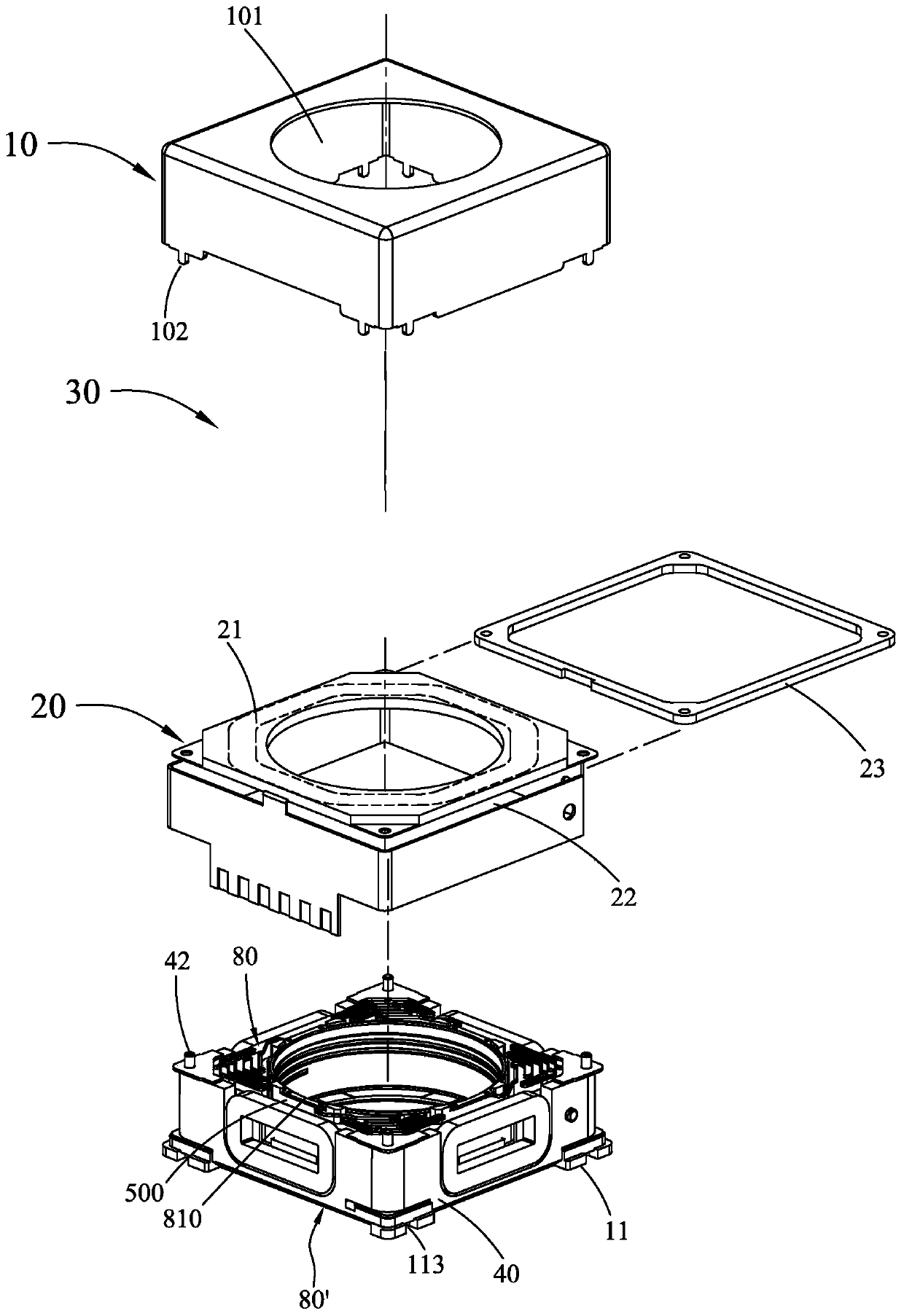

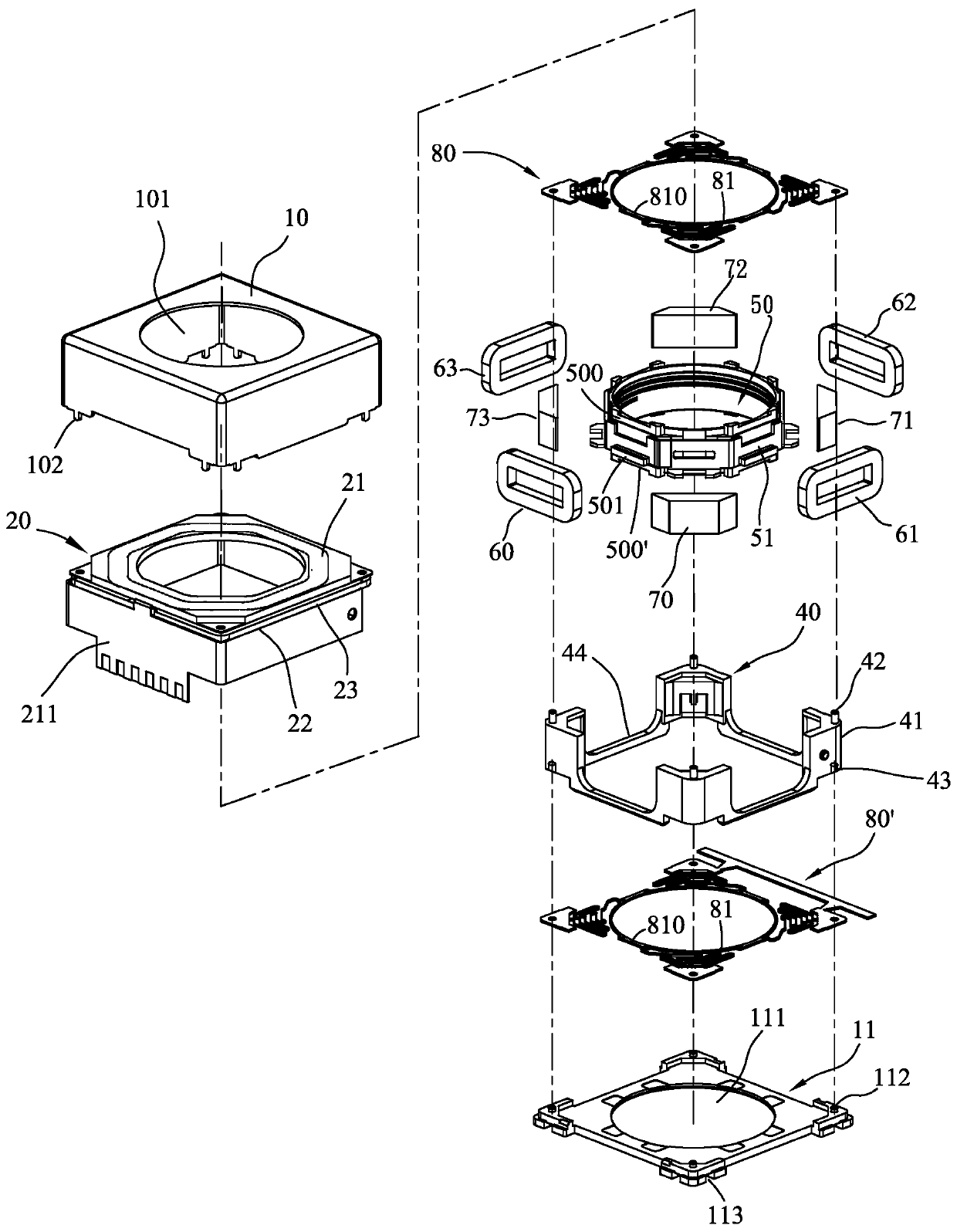

[0056] Please see figure 1 , figure 2 , image 3 As shown, the present invention at least includes:

[0057] A non-magnetic permeable upper cover 10 and a base 11 all have a middle hole 101, 111, which can be fitted with nail claws 102 and buckle grooves 113 to form the outer shell of the anti-shock system; wherein the base 11 and There are stud posts 112 combined with internal components at four corners.

[0058] A flexible circuit board 20, located in the inside of the outer shell, has a flexible board coil 21 in a horizontal direction, and a vertical circuit substrate 211 connected by the side of the flexible board coil 21, and the flexible board coil 21 and the circuit A gap 22 is formed between the substrates 211; a spacer 23 is accommodated in the gap 22 to provide a movable stroke of the mover part in the Z-axis movement direction; image 3 The shown flexible circuit board 20 is connected with a vertical circuit substrate 211 surrounded by four sides by one side o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com