Automatic centering plugging method for electric connector

An electric connector and automatic centering technology, which is applied in the connection/disconnection of connection devices, instruments, measuring devices, etc., can solve the problems of electrical connector plugs and sockets that cannot be centered, axis position deviation, wear, etc. The effect of centering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing.

[0020] A method for automatic centering and plugging of an electrical connector, specifically as follows:

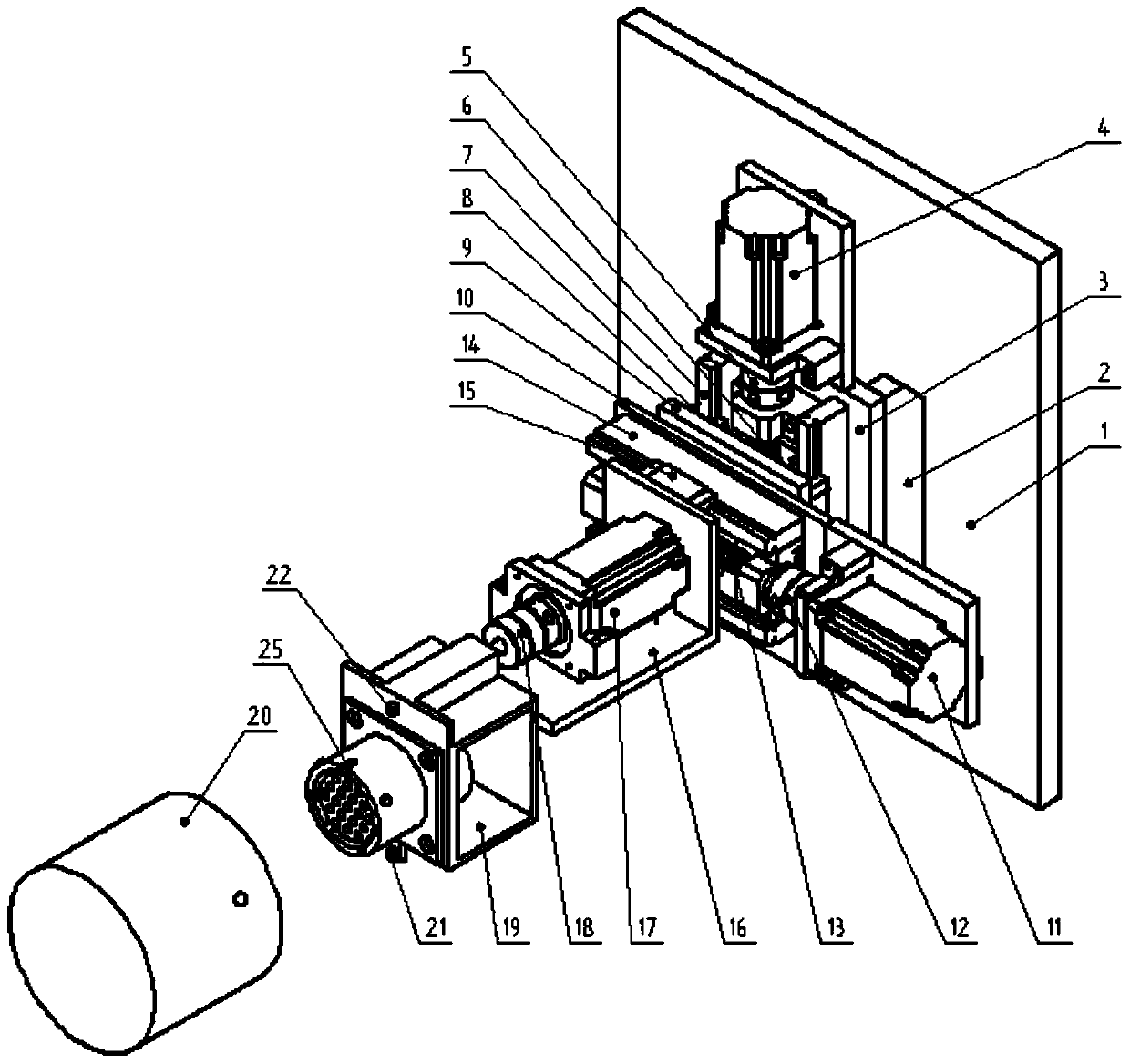

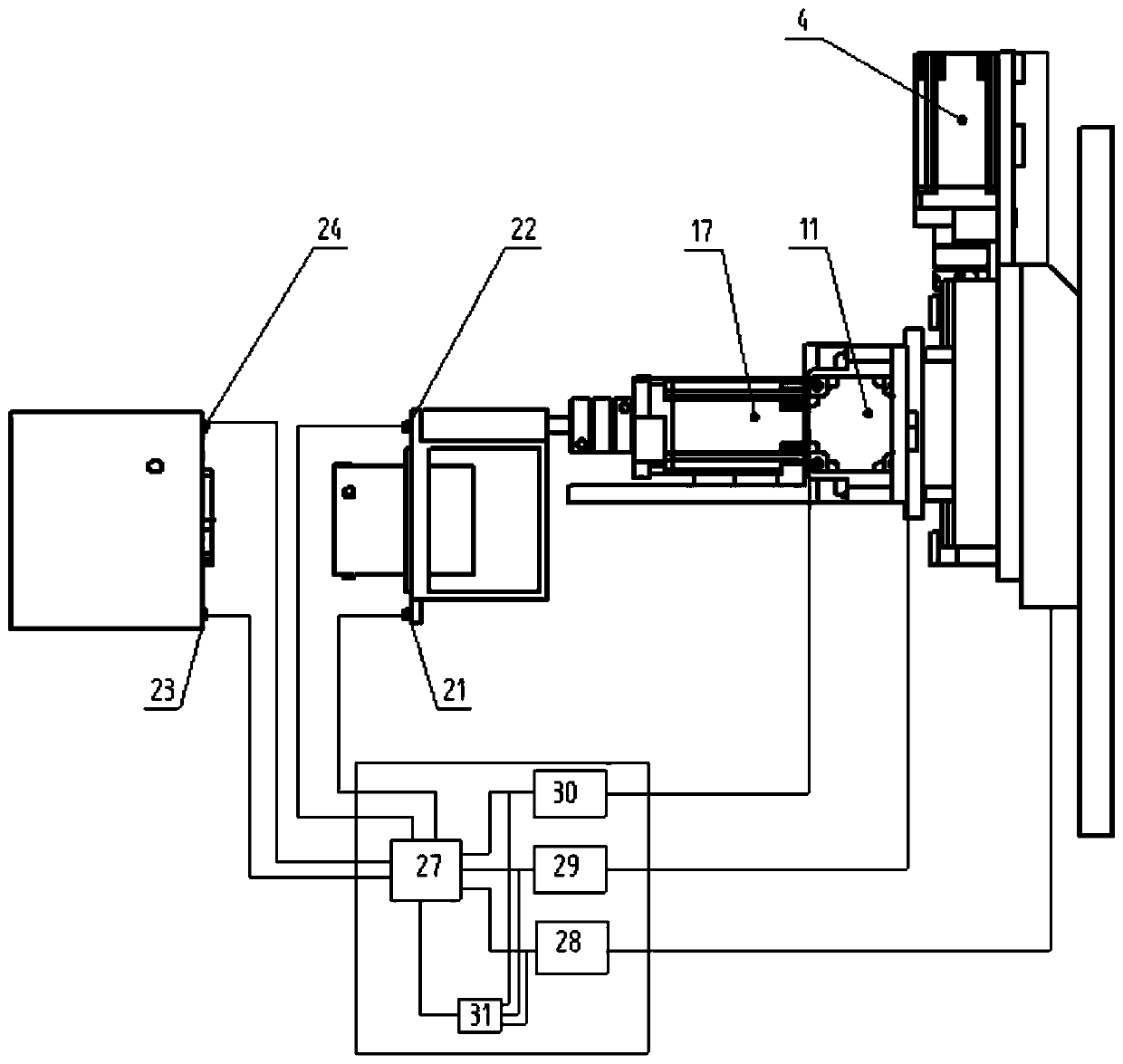

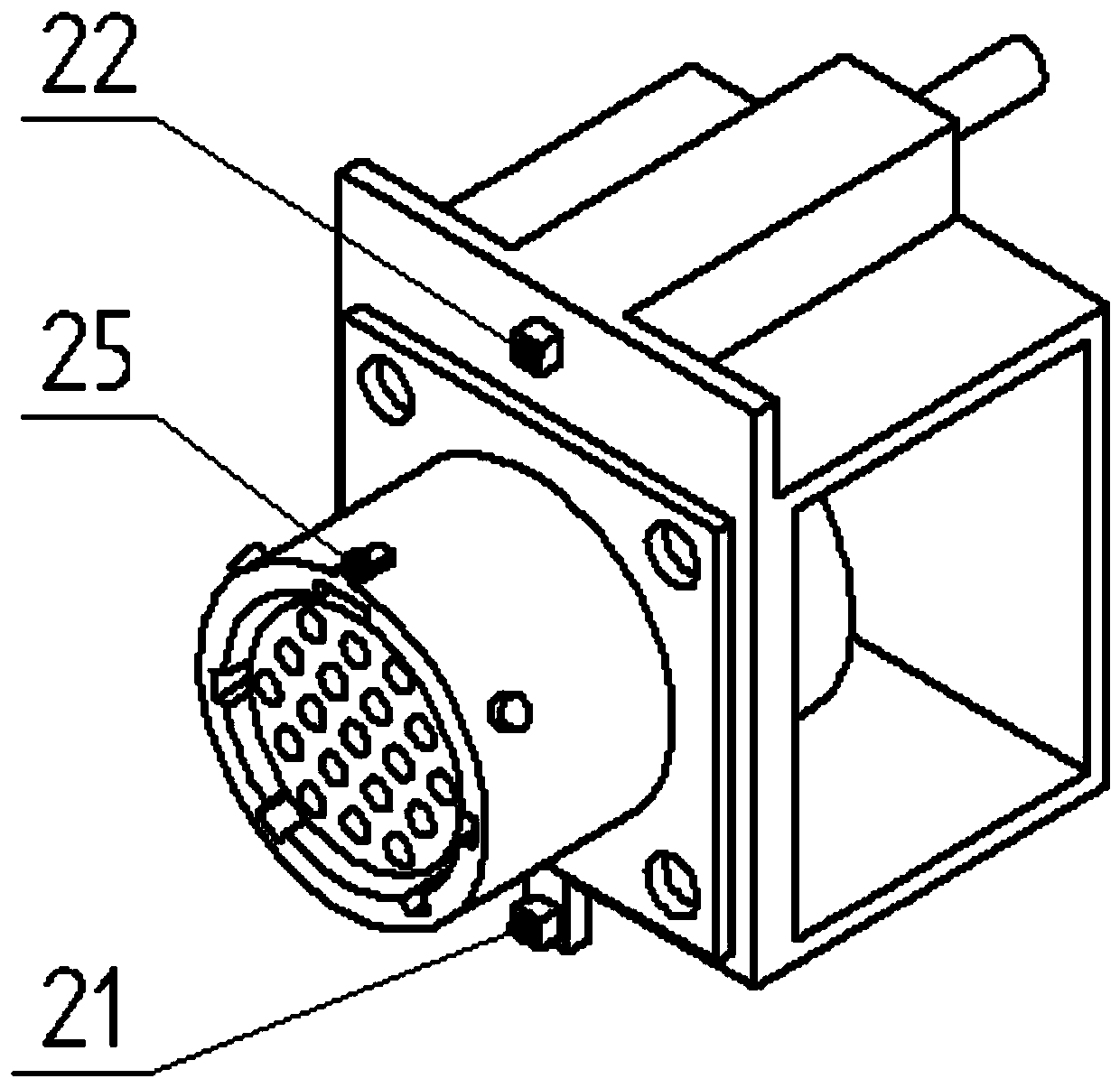

[0021] 1) if figure 1 , image 3 and Figure 4 As shown, the base of the rotating servo motor 17 is fixed on the X-axis traveling plate 16 of the XZ axis two-dimensional slide table, and the output shaft of the rotating servo motor 17 is connected to the installation shaft fixed on the electrical connector socket fixture 19 through a rotating coupling. The shaft device 18 is connected; the transmitting end 21 of the first through-beam photoelectric sensor and the transmitting end 22 of the second through-beam photoelectric sensor are all fixed on the electrical connector socket fixture 19, and the transmitting end of the second through-beam photoelectric sensor 22 is located on the central axis of the installation shaft fixed with the electrical connector socket fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com