Assembling device and method for pen refill connecting piece

An assembly device and assembly method technology, applied in assembly machines, metal processing, metal processing equipment, etc., can solve problems such as breakage, inclined position of the refill connector, and misalignment of the refill connector, so as to solve the problem of incorrect position. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

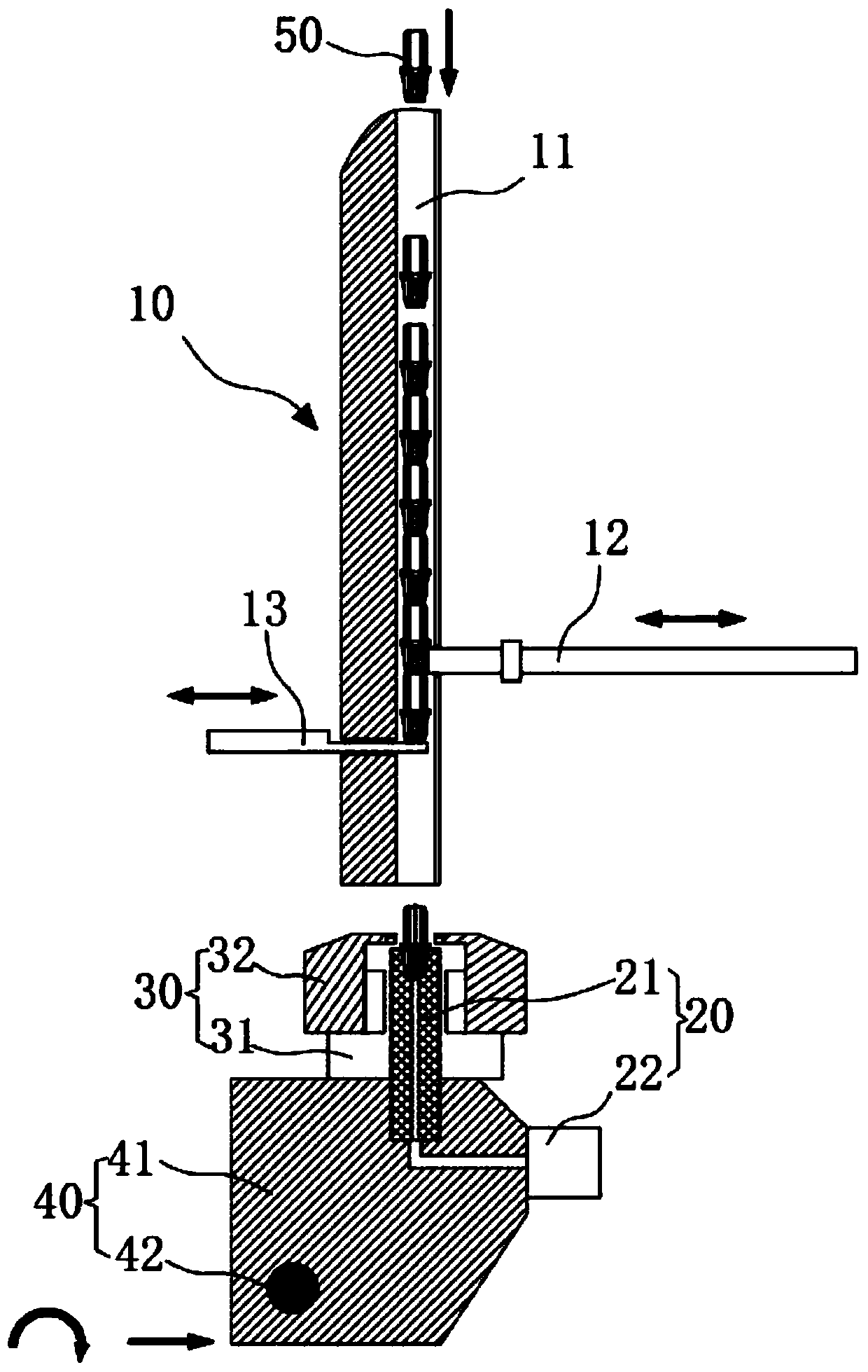

[0029] The technical solutions of the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings of the present invention.

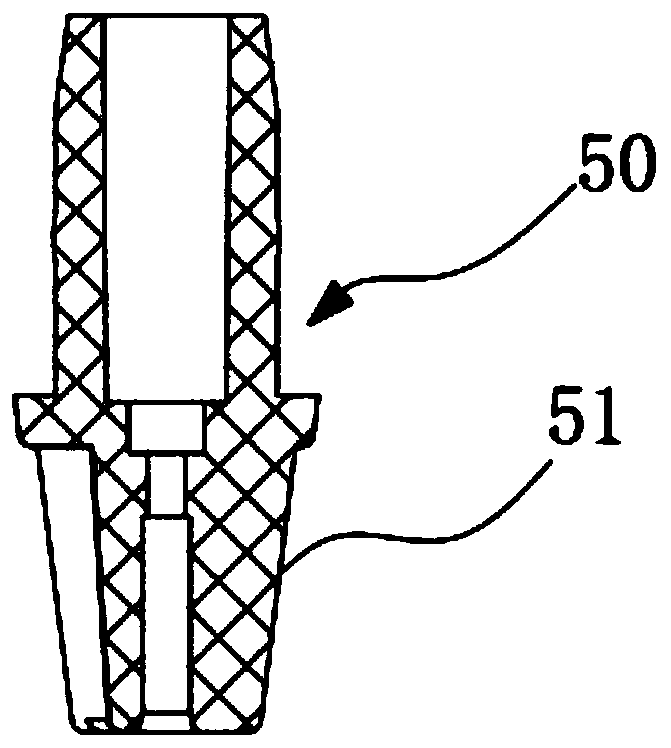

[0030] Such as figure 2 As shown, an assembly device for a refill connector disclosed in a preferred embodiment of the present invention includes: an unloading mechanism 10, a suction nozzle assembly 20, a clamping assembly 30, and an overturning mechanism 40, wherein the unloading mechanism 10 will carry The refill connector 50 is transported to the suction nozzle assembly 20 for suction, then the clamping assembly 30 clamps and adjusts the refill connector 50 in the nozzle assembly 20, and finally the overturning assembly 40 drives the refill connector 50 to turn over, ready to Enter the next step of the assembly process (such as loading the pen core tube).

[0031] Specifically, before the unloading mechanism 10, the refill connector 50 is arranged and ordered by a feeding device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com