High-order SH guided wave imaging detection method and system for rail bottom cracks of steel rail

A technology for imaging detection and rail bottom, which is applied in measuring devices, processing response signals of detection, and analyzing solids using sonic/ultrasonic/infrasonic waves, which can solve the problem of inability to achieve efficient online detection of rail bottom cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

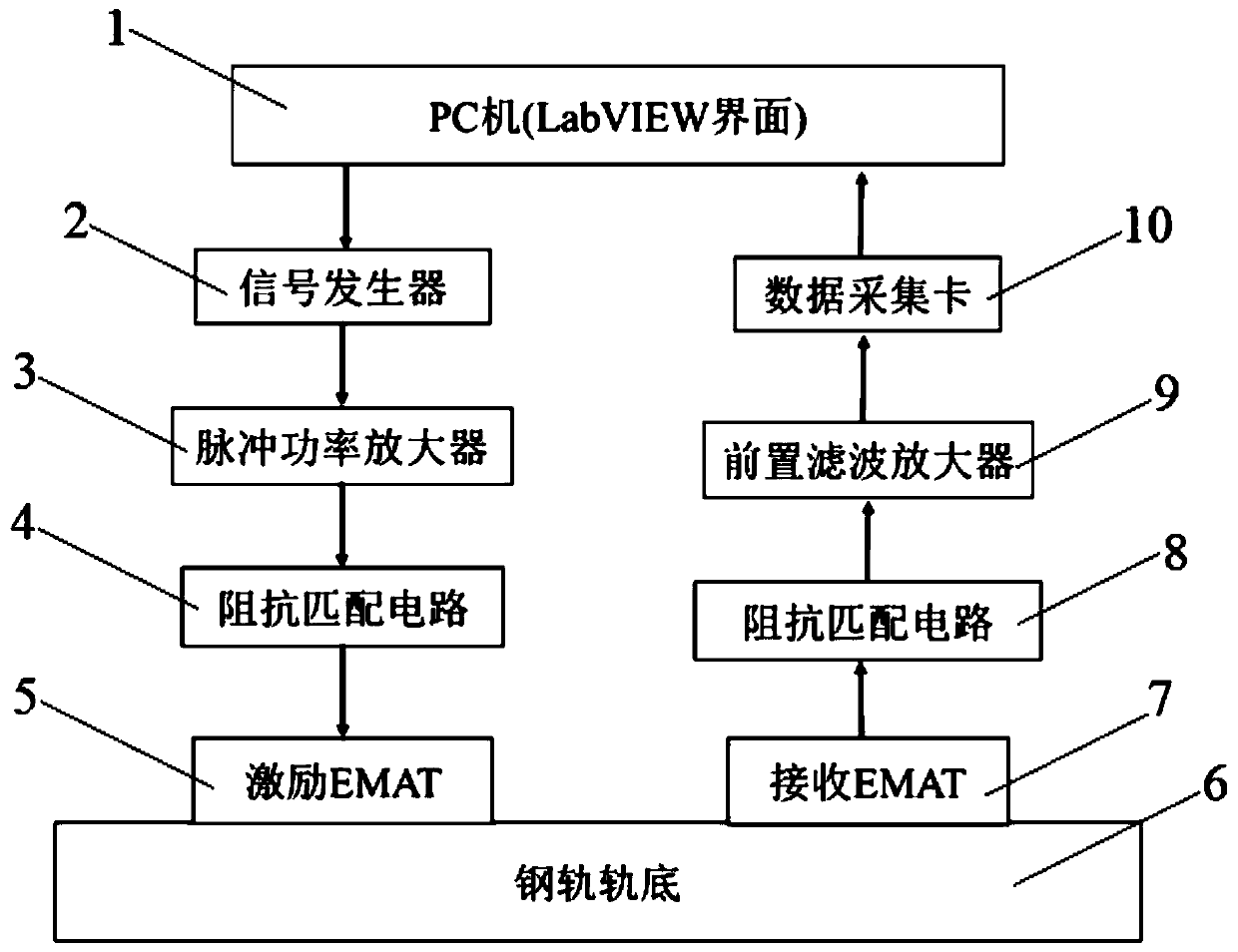

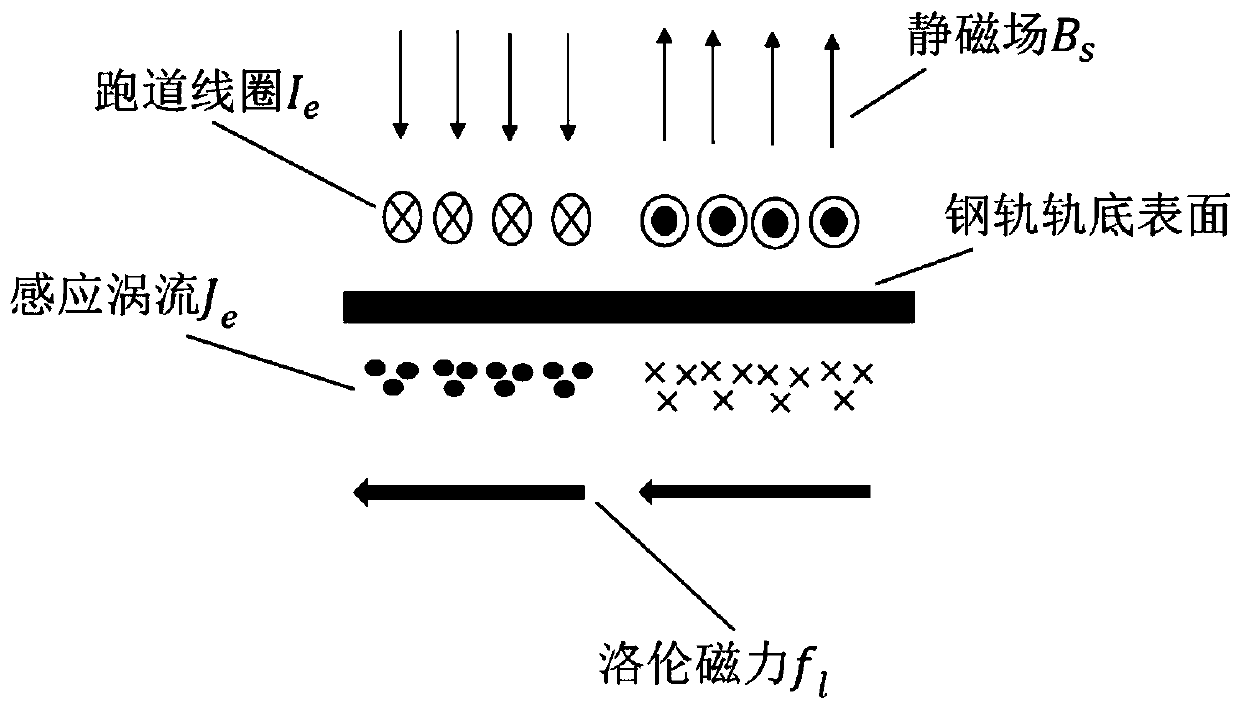

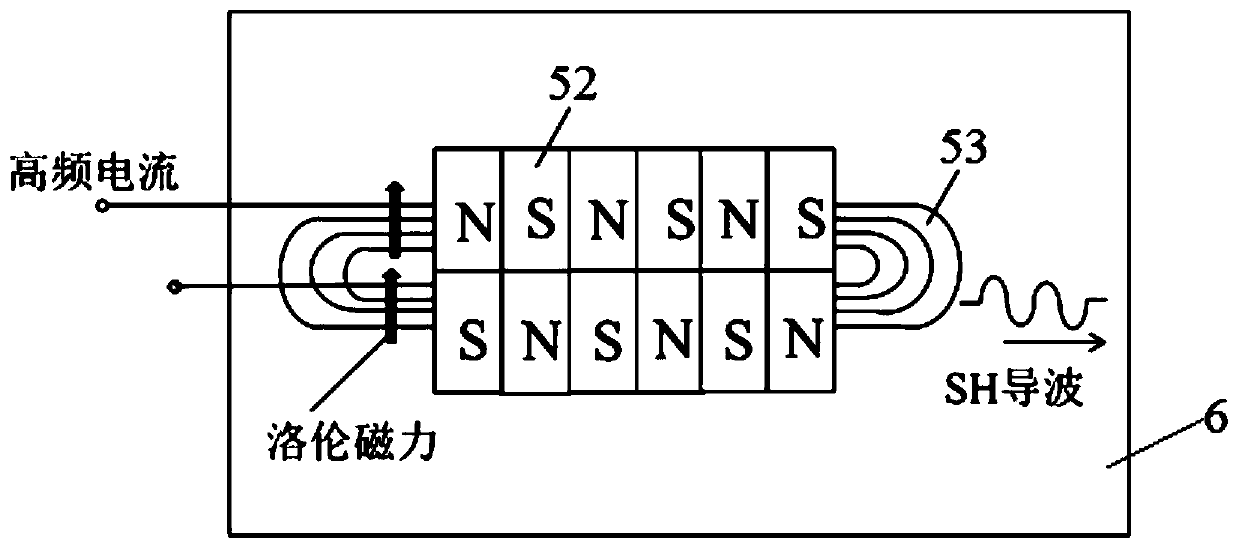

[0071] Such as figure 1 and Figure 5 As shown, this embodiment provides a high-order SH guided wave imaging detection system for rail bottom cracks, including a PC 1, a signal generator 2, a pulse power amplifier 3, a first impedance matching circuit 4, an electromagnetic ultrasonic SH guided wave excitation probe (exciting EMAT) 5; also includes electromagnetic ultrasonic SH guided wave receiving probe (receiving EMAT) 7, the second impedance matching circuit 8, pre-filter amplifier 9, data acquisition card 10 connected in sequence, the data Acquisition card 10 is also connected with described PC machine 1;

[0072] The signal generator 2 is used to receive the excitation command of the PC 1 and generate a sinusoidal pulse train current;

[0073] The pulse power amplifier 3 is used to amplify the sinusoidal pulse train current generated by the signal generator 2, and transmit it to the electromagnetic ultrasonic SH guided wave excitation probe 5 through the first impedance...

Embodiment 2

[0106] This embodiment provides a high-order SH guided wave imaging detection method for rail bottom cracks, including:

[0107] An electromagnetic ultrasonic SH guided wave excitation probe and an electromagnetic ultrasonic SH guided wave receiving probe are arranged at intervals on the bottom surface of the rail to be tested;

[0108] A sinusoidal pulse train current that can excite SH guided waves from the bottom of the rail is fed into the electromagnetic ultrasonic SH guided wave excitation probe;

[0109] The electromagnetic ultrasonic SH guide wave receiving probe receives the reflected echo and transmits the signal to the PC to obtain a set of detection echo signals;

[0110] Keep the distance between the electromagnetic ultrasonic SH guided wave excitation probe and the electromagnetic ultrasonic SH guided wave receiving probe unchanged, and move the two along the length of the rail bottom to be measured at a preset step length, and repeat the above steps to obtain mu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com