Flexible touch type plant sensor, harvester and method

A sensor and harvester technology, applied in the field of sensors, can solve problems such as unfavorable accurate detection, collision damage of plants, and unfavorable harvesting of vegetables and other crops, so as to achieve accurate detection results and avoid interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

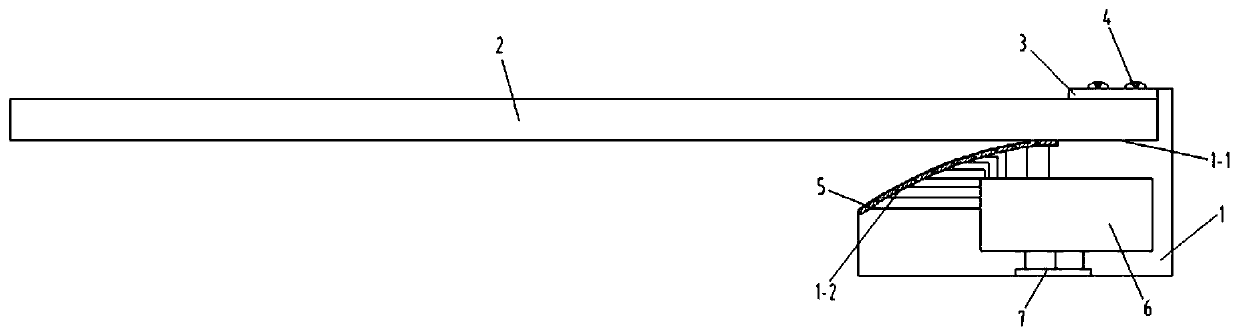

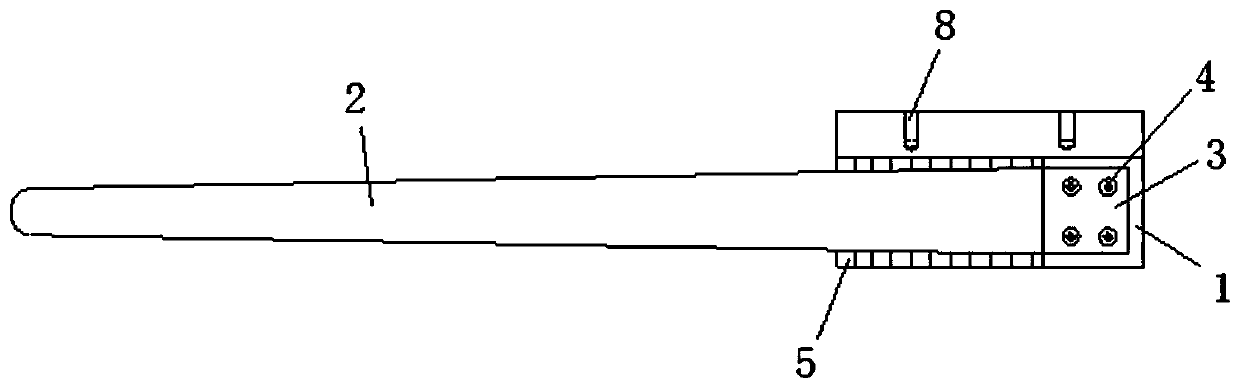

[0034] This embodiment discloses a harvester, the front end of the harvesting platform is fixedly connected to the flexible touch-type plant body detection sensor described in Embodiment 1 through a threaded mounting hole, and the output terminal on the housing is connected to the harvester through a connecting wire. Machine controller connection.

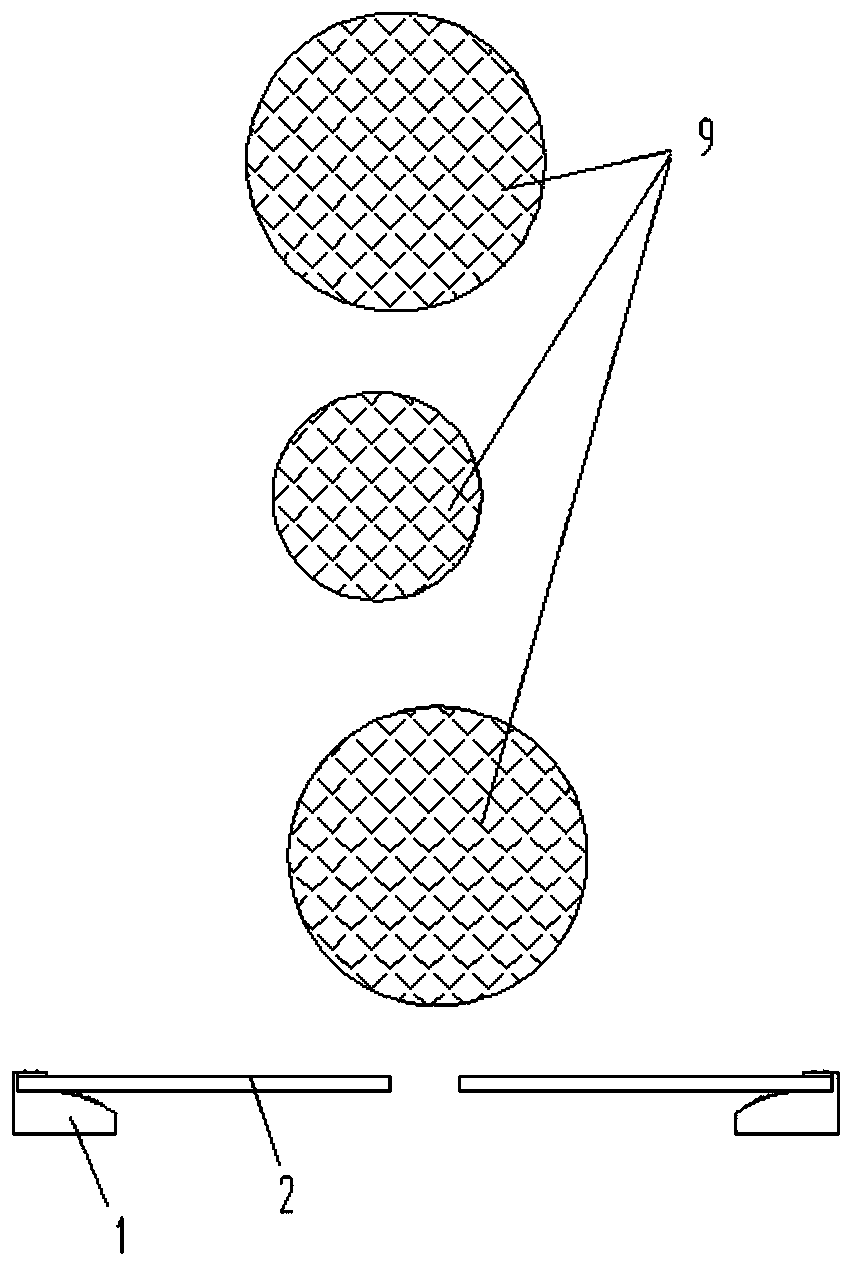

[0035] Two flexible touch-type plant body detection sensors described in Embodiment 1 are installed on the harvesting platform of the harvester, and the movable ends of the two flexible touch-type plant body detection sensors are arranged close to each other, which can detect the movement of the harvester. The offset can also detect the volume and outer contour of the plant body.

[0036] In another embodiment, two flexible touch-type plant body detection sensors described in Embodiment 1 are installed on the harvesting platform of the harvester. The row offset of the harvester.

Embodiment 3

[0038] This embodiment discloses a working method of the flexible touch-type plant body detection sensor described in Embodiment 1. When the touch bar touches the crop plant body, it will be bent and deformed, and the touch bar will be squeezed after being bent and deformed. The pressure strain gauges of the pressure strain gauge group, so that the pressure strain gauges generate voltage signals, each pressure strain gauge on the pressure strain gauge group can output an independent signal to the signal processor, when the crop plant is closer to the sensor, the flexible touch The greater the bending deformation of the touch strip, the flexible touch strip will sequentially squeeze the pressure strain gauges on the strain gauge group with the increase of the bending deformation, and the position of the maximum extrusion force will also change on the pressure strain gauges. The signal processor analyzes each The pressure change of a pressure strain gauge can analyze the bending ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com