A composite support structure, construction system and method

A supporting structure and composite technology, which is applied in earth-moving drilling, shaft equipment, wellbore lining, etc., can solve the problems of insufficient bearing capacity of supporting structure, affecting coal mining efficiency, slow roadway forming, etc., shortening construction time, The effect of enhancing support strength and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

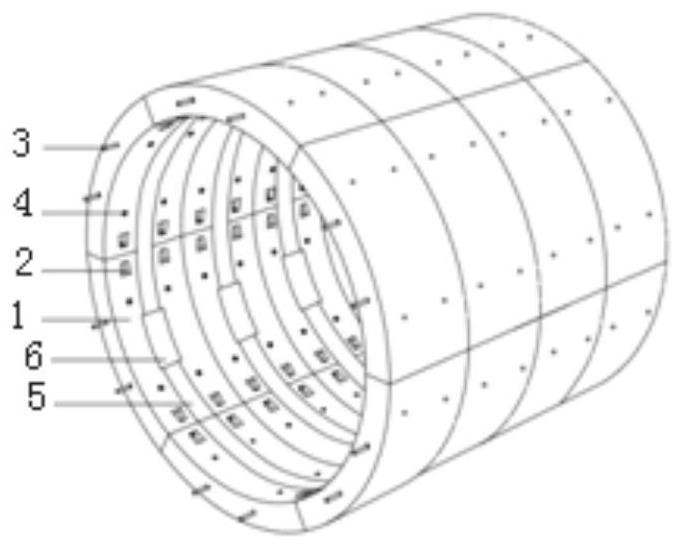

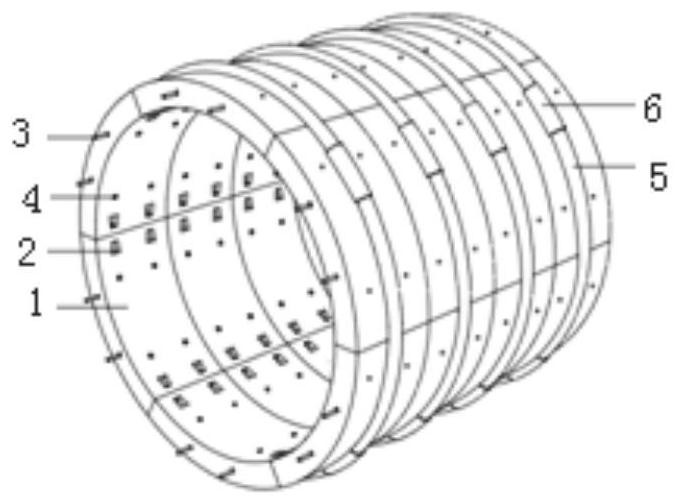

Examples

Embodiment 2

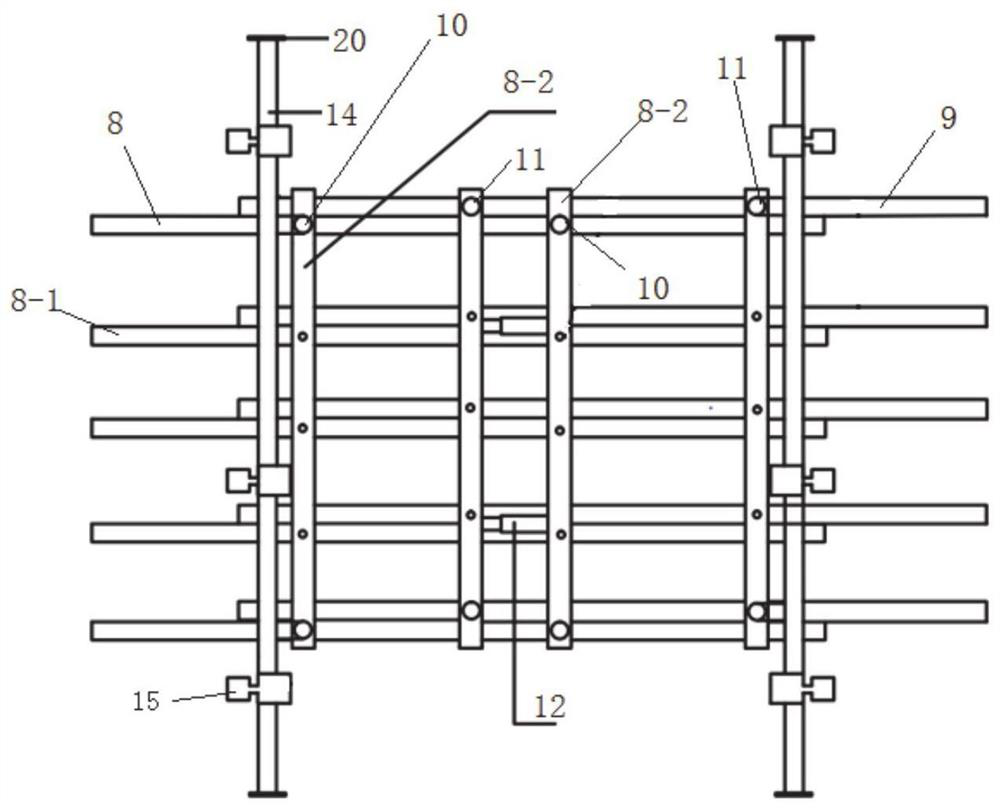

[0043] This embodiment discloses a construction system of the composite support structure described in Embodiment 1, such as image 3 As shown, it includes roadheader, bolt construction device, arc plate construction device and steel pipe construction device.

[0044]When constructing the support structure with the reinforced concrete ring inside the arc-plate ring, the roadheader, anchor rod construction device, arc-plate construction device and steel pipe construction device are set in sequence in the roadway for simultaneous construction. The roadheader is used to excavate the roadway. The bolt construction device is used to construct the bolt, the arc plate construction device constructs the arc plate ring on the tunnel part where the anchor rod has been constructed, and the steel pipe construction device is used to construct the steel pipe concrete ring on the inner side of the constructed arc plate ring.

[0045] When the construction reinforced concrete ring is located ...

Embodiment 3

[0088] Such as Figure 13 As shown, this embodiment discloses a working method of the construction system described in Embodiment 2: taking the supporting structure where the steel pipe concrete ring is located inside the arc plate ring as an example, it includes the simultaneous anchor construction process, arc Plate construction process and steel pipe construction process.

[0089] The construction method of the bolt construction procedure is as follows: the roadheader 7 excavates the roadway to excavate the roadway space, the bolt construction device moves synchronously with the roadheader under the drive of the first traveling mechanism, and after the roadheader excavates the roadway, Stop working, the first hydraulic cylinder and the second hydraulic cylinder drive the first support part and the second support part to break away from the roadway top surface, and the construction personnel erect the anchor net 47 on the inner wall of the roadway, and the construction metho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com