Fabricated wall building block and fabricated construction method of wall building block

A construction method and assembly technology, applied in the direction of walls, building components, buildings, etc., can solve the problems of environmental pollution, labor and materials, and achieve the effect of simple and fast assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

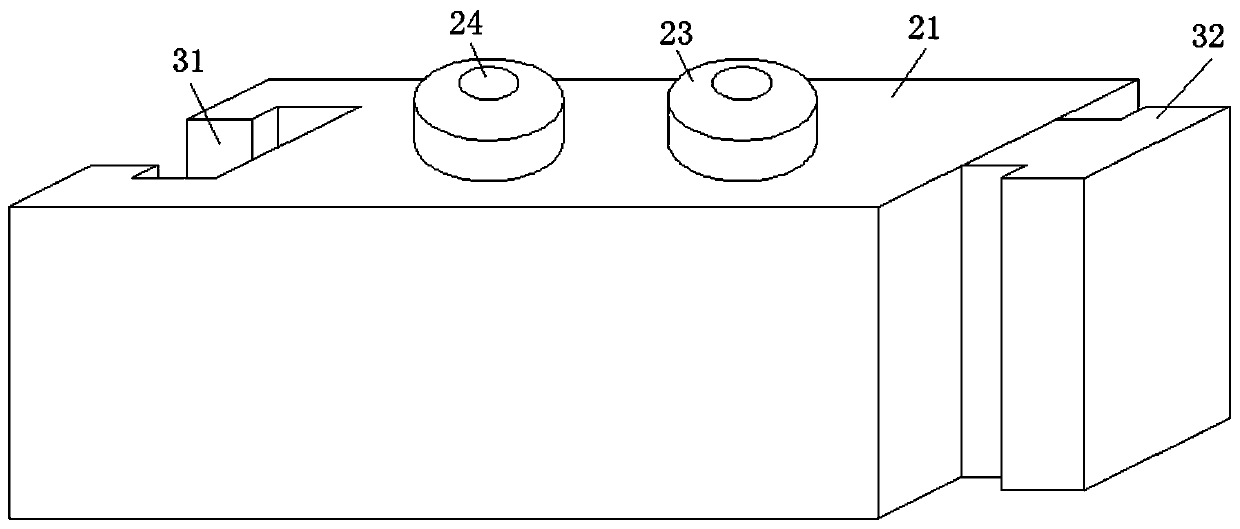

[0029] Such as figure 1 As shown, this embodiment adopts the following technical solutions:

[0030] A prefabricated wall block, comprising a wall base 1, a number of block structures 2 are provided in a cross shape above the wall base 1, each of the block structures 2 is provided with A clamping mechanism 3, at least one cover pressing structure 4 is arranged on the several block structures 2.

[0031] As a result, the assembly of the wall blocks is relatively simple and fast, and at the same time, the block structures are better fixed through the clamping mechanism and the cover plate pressurization structure, which is more stable and reliable. And it can also be dismantled for recycling and reuse, avoiding excessive waste of resources.

Embodiment 2

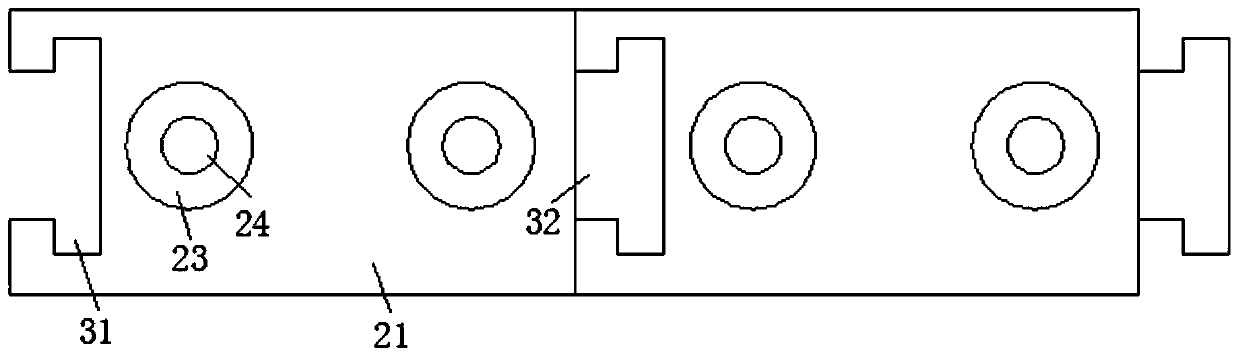

[0033] Please refer to Figure 2 ~ Figure 6 , this embodiment specifically includes:

[0034] Wherein, the wall base 1 includes a base 11 . The upper surface of the base 11 is fixedly connected with several first positioning blocks 12 evenly and equidistantly in a matrix, and the top of each first positioning block 12 is arranged in an arc shape, and the upper surface of each first positioning block 12 is A support rod 13 is fixedly connected vertically, and each support rod 13 is arranged as a ribbed steel bar.

[0035] Wherein, each block structure 2 includes a block 21 , and the lower surface of each block 21 is provided with more than two first positioning grooves 22 . In this embodiment, for example, two first positioning grooves 22 are illustrated, and every two adjacent first positioning grooves 22 are respectively spaced the same as every two adjacent first positioning blocks 12 . A second positioning block 23 is fixedly arranged on the upper surface of each block 2...

Embodiment 3

[0048] This embodiment provides a prefabricated construction method for wall blocks, including the following working steps:

[0049] (1), first plan the base 11 according to the requirements, and determine the position and length of the base 11, then embed and fix the base 11 through concrete, and adjust the leveling and angle of the base 11, after the adjustment is completed Finally, the concrete is dried, and then the installation of the base 11 is completed.

[0050] (2) Form a sealant layer on several blocks 21 up, down, left, and right, and then align and insert the two support holes 24 on the block 21 with the two adjacent support rods 13 respectively. And several blocks 21 are placed in a cross pattern, so that the blocks 21 are cross-fixed through the cooperation of the first positioning groove 22 and the second positioning block 23 . At the same time, the adjacent blocks 21 can also be fixed again through the engagement between the T-shaped hole 31 and the T-shaped b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com