Blending process of oil-gas exploration drilling waste water-based drilling fluid

A water-based drilling fluid and exploratory drilling technology, applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problem of low temperature resistance, gypsum salt resistance and salt water pollution, insufficient water loss and wall building, and rheological properties Poor problems, to avoid downhole accidents and complex, easy maintenance and treatment, to prevent the effect of wall collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

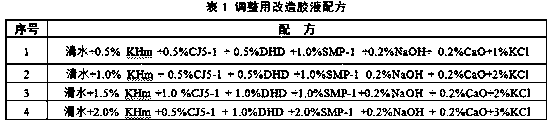

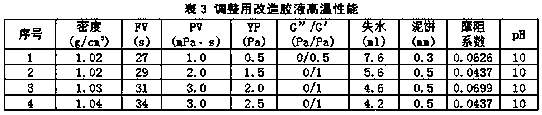

Embodiment 1

[0022] As a preferred embodiment of the present invention, it discloses a blending process of waste water-based drilling fluid for oil and gas exploration drilling, which is characterized in that it includes a step of treating waste water-based drilling fluid and a step of preparing glue; The waste water-based drilling fluid is treated to control the solid phase content and sand content in the waste water-based drilling fluid; the preparation step of the modified glue is: adding 0.5% potassium humate KHm to clear water in terms of mass percentage , 0.2% NaOH, 0.2% CaO, 0.5% zwitterionic polymer viscosity reducer CJ5-1, 0.5% plugging lubricant DHD, 1% sulfonated phenolic resin SMP-1 and 1% KCl; the rest is water; then The prepared reforming glue and the treated waste water-based drilling fluid are mixed at a ratio of 20-30:80-70 to complete the deployment of the waste water-based drilling fluid.

[0023] The described treatment of the waste water-based drilling fluid is to pass...

Embodiment 2

[0026]On the basis of Example 1, the preparation steps of the modified glue solution are: in terms of mass percentage, add 1% potassium humate KHm, 0.2% NaOH, 0.2% CaO, 0.5% zwitterionic polymer Adhesive CJ5-1, 0.5% blocking lubricant DHD, 1% sulfonated phenolic resin SMP-1 and 2% KCl; the rest is water.

Embodiment 3

[0028] On the basis of Example 1, the preparation steps of the modified glue solution are: in terms of mass percentage, add 1.5% potassium humate KHm, 0.2% NaOH, 0.2% CaO, 1% zwitterionic polymer Adhesive CJ5-1, 1% blocking lubricant DHD, 1% sulfonated phenolic resin SMP-1 and 2% KCl; the rest is water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com