Automatic perforating integrated machine for film blowing machine

The technology of a film blowing machine and an all-in-one machine is applied in the field of agricultural appliances, which can solve the problems of wasting time, large labor expenditure, labor and crop damage, and achieve the effects of reducing labor intensity, improving production efficiency, and reducing high labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

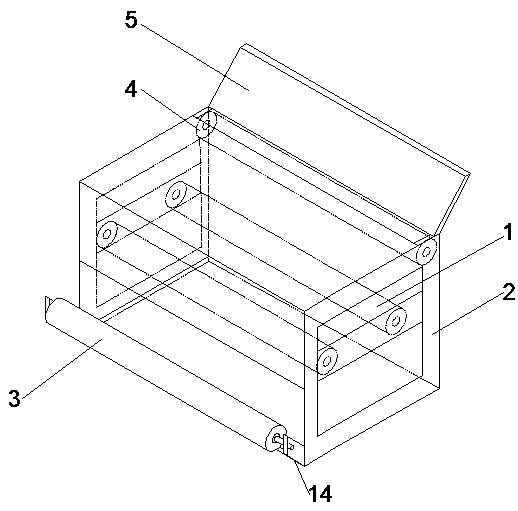

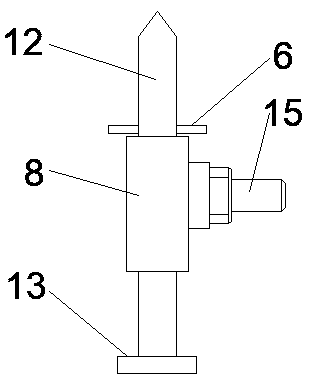

[0019] Such as Figure 1-Figure 4 As shown, a blown film machine automatic punching integrated machine includes a frame 2, the upper part of the frame 2 is provided with a material inlet, the front side of the frame 2 is provided with a discharge port, and the inside of the frame 2 is horizontally provided with two film spreading rollers 1, The lower part of the two stretching rollers 1 is provided with a punching mechanism with adjustable drill spacing. The feeding port is provided with a discharge plate 5 which is inclined. The film mechanism, the film roll mechanism includes a support vertical plate 14, the support vertical plate 14 is arranged on both sides of the discharge port, the film roll 3 is horizontally arranged on the support vertical plate 14, and the two ends of the film roll 3 are vertically connected with the support through the installation shaft. The connecting shaft provided on the side wall of the plate 14 is connected by mortise and tenon. The mortise and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com