Mobile positioning punching device for textile processing

A punching device and mobile technology, which is applied in the cutting of textile materials, metal processing, textiles and paper making, etc., can solve the problems of non-adjustable pressure, single function of the splint, and slow drug delivery to the affected area, so as to improve the punching rate. Effect of Pore Efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

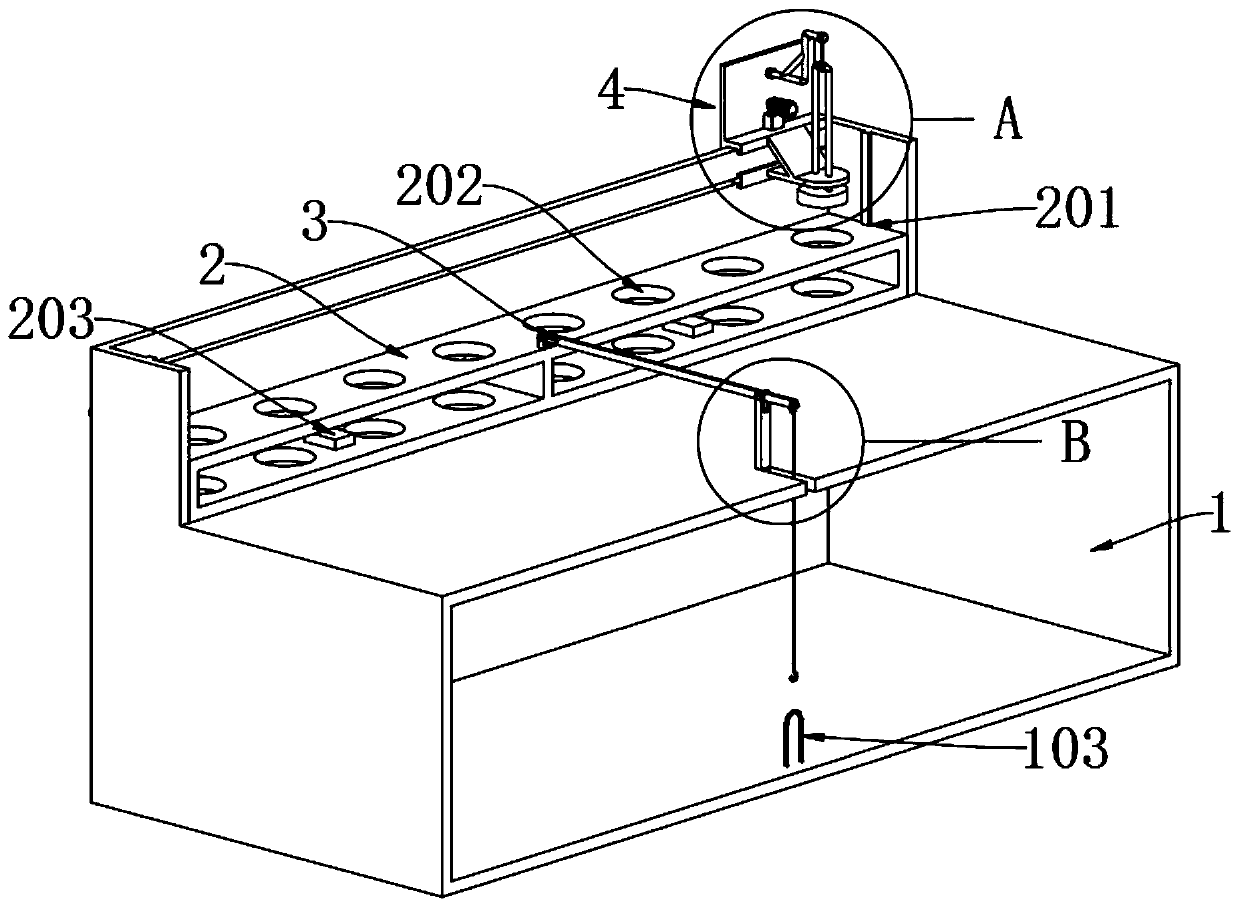

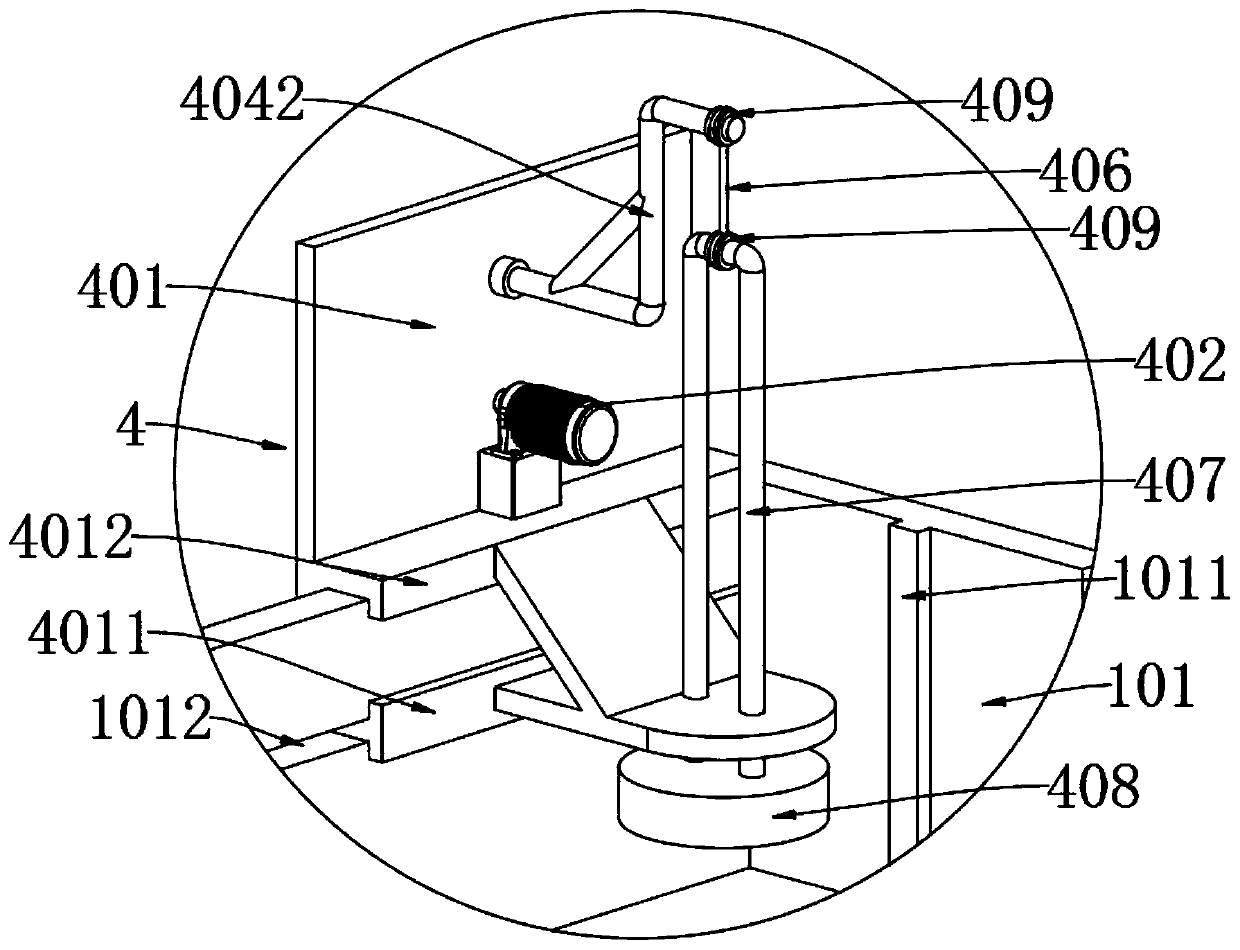

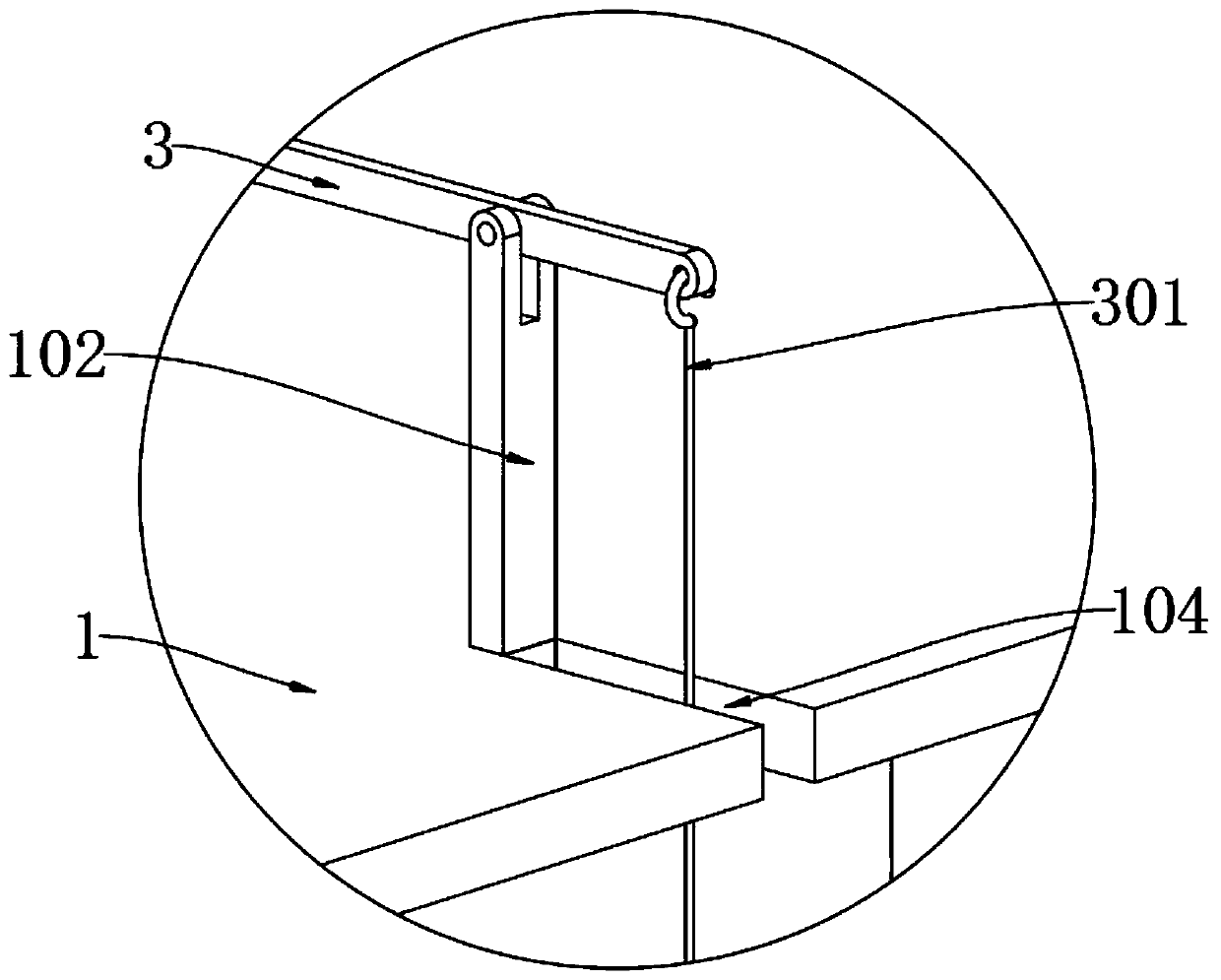

[0033] as attached figure 1 to attach Figure 9 Shown:

[0034]The present invention provides a mobile positioning and punching device for textile processing, which includes a device main body 1 and a platen frame 2; The slide rail 1011 of the vertical structure, the platen frame 2 is slidably mounted in the side groove 101, and the two ends of the platen frame 2 are provided with the slide grooves 201 of the vertical structure and are slidably engaged with the slide rail 1011, the platen frame 2 is There are eight groups of pressing holes 202 aligned up and down in turn, and two groups of counterweights 203 are fixedly installed on the inner bottom end of the pressing plate frame 2, and the middle outer end of the pressing plate frame 2 is also hinged with a pressing bar 3, and the pressing bar The rear end of 3 is hung with lanyard 301 and is rotated and inserted on the strut 102. The lower end of lanyard 301 passes through opening 104 and is connected with a hook, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com