A mining explosion-proof permanent magnet synchronous frequency conversion traction motor wiring device

A traction motor and permanent magnet synchronous technology, which is applied in the field of motors, can solve the problem that terminal sleeves cannot be arranged, special stop gaskets, terminal clearances and creepage distances cannot meet standard requirements, and mine flameproof permanent magnets cannot be designed and improved. Problems such as magnetic synchronous variable frequency traction motor to achieve the effect of reducing space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

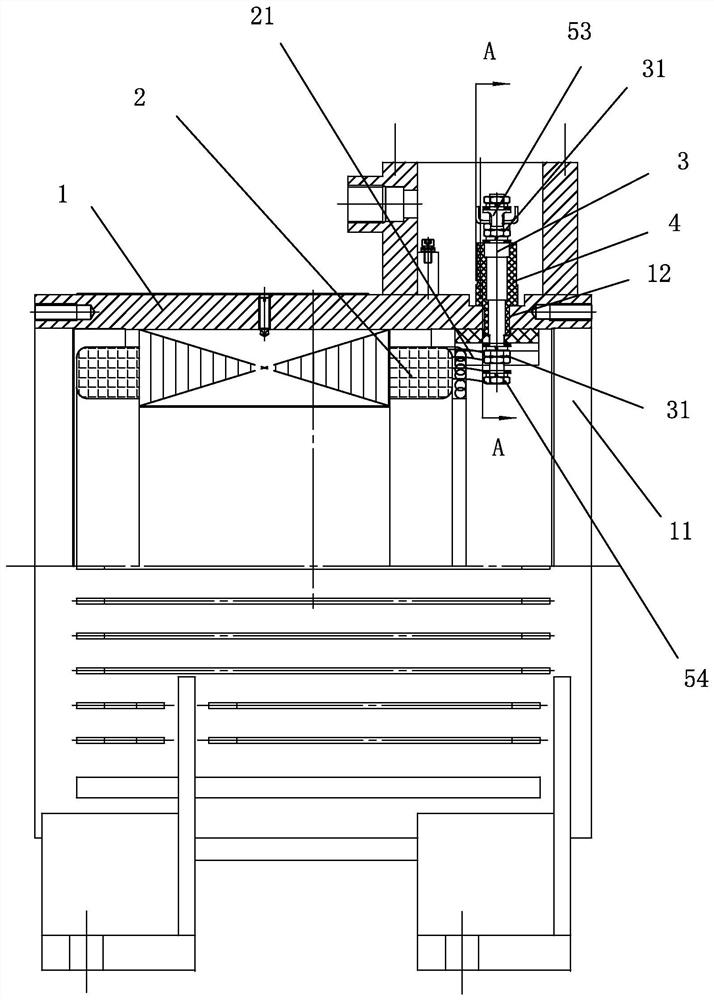

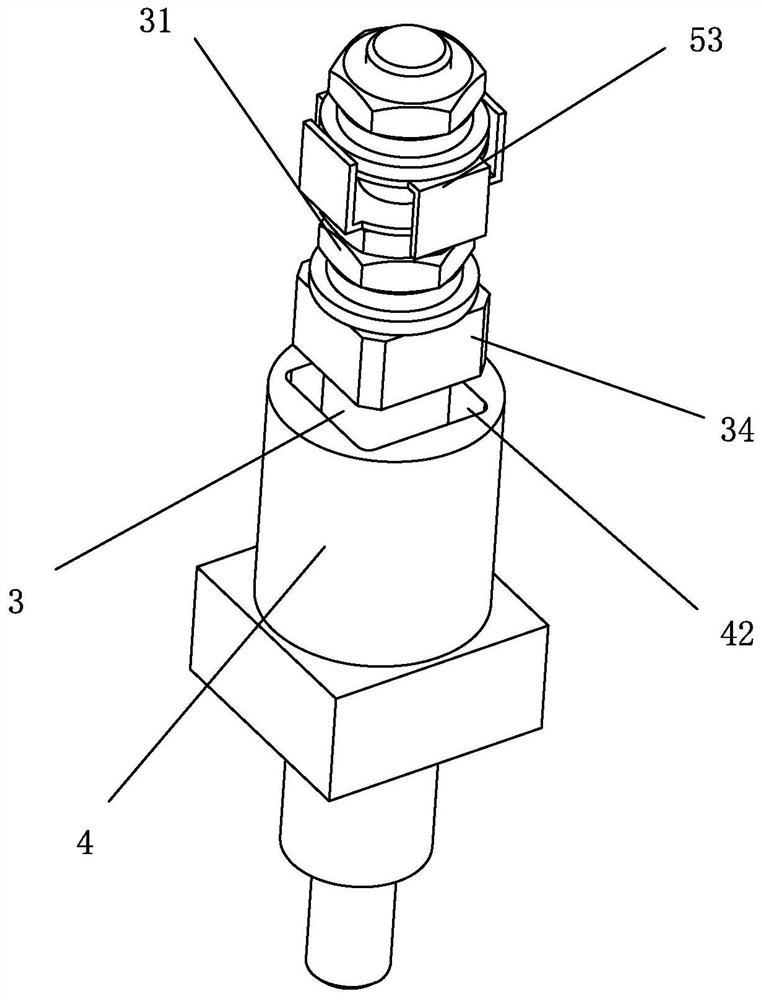

[0026] see Figure 1 to Figure 3 As shown, a mining explosion-proof permanent magnet synchronous variable frequency traction motor wiring device of the present invention includes a frame 1, a stator winding 2, a terminal bolt 3 and an insulating sleeve 4; the frame 1 is cylindrical and has Openings 11 on both sides, the stator winding 2 is installed in the cylinder wall of the base 1, and has a preset distance from one of the openings 11 of the base 1; at the preset distance There is a first through hole 12 penetrating through the cylinder wall, the insulating sleeve 4 is fixed outside the cylinder wall of the base 1 through the first through hole 12 and the bottom end of the insulating sleeve 4 extends into the In the cylinder wall; the terminal bolt 3 is penetrated and fixed in the insulating sleeve 4 and the upper end of the terminal bolt 3 is exposed to the top of the insulating sleeve 4, and the lower end of the terminal bolt 3 is exposed to the The bottom end of the ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com