A Single-loop Superheated Steam Temperature Active Disturbance Rejection Control Method with Disturbance Compensation

A technology of active disturbance rejection control and superheated steam temperature, applied in the direction of adaptive control, general control system, control/adjustment system, etc., can solve the problems of difficult parameter setting and complex structure, achieve good control effect, simplify control structure, The effect of overcoming systematic bias

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] A single-loop superheated steam temperature ADR control method with disturbance compensation proposed by the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

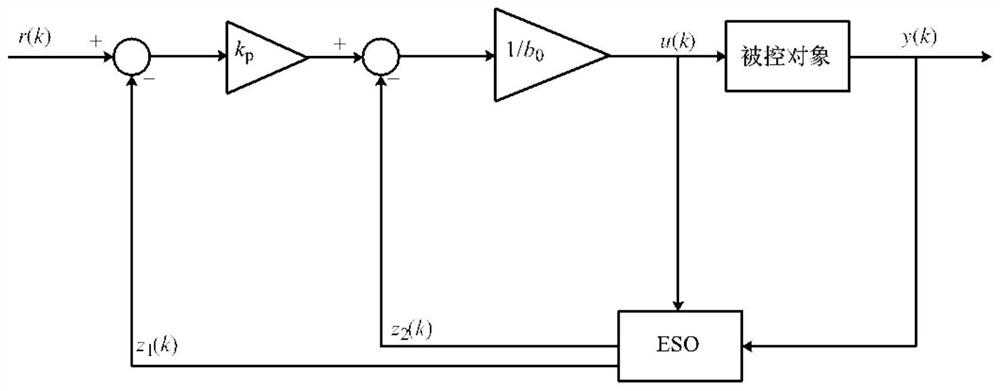

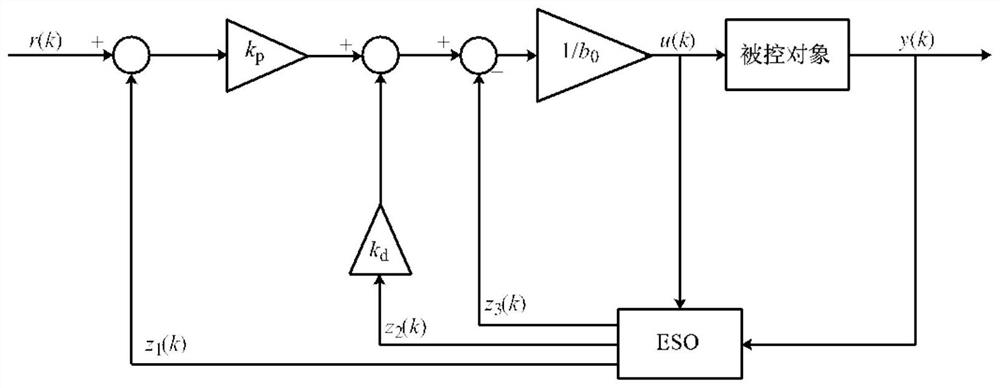

[0046] The present invention proposes a disturbance-compensated single-loop ADR control method for superheated steam temperature systems, including first-order and second-order ADR control methods, which are described as follows.

[0047] Figure 4 It is a flow chart of the disturbance compensation single-loop first-order active disturbance rejection control designed for the superheated steam temperature system of the present invention, and its specific steps are as follows:

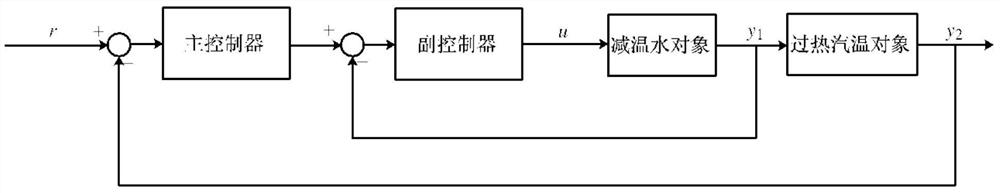

[0048] 1) Define the transfer function relationship between the superheater inlet steam temperature and the desuperheating water valve opening as the secondary object, and the transfer function relationship between the superheater outlet steam temperature and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com