Device and method for measuring frictional resistance of horizontal swivel spherical hinge interface

A technology for measuring device and frictional resistance, applied in the direction of measuring device, adopting mechanical device, force/torque/work measuring instrument, etc., can solve the problem of lack of frictional resistance measurement test of indoor horizontal swivel spherical hinge interface, etc., achieve good and can be extended performance, avoiding lateral force, and avoiding the effect of lateral force on spherical joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

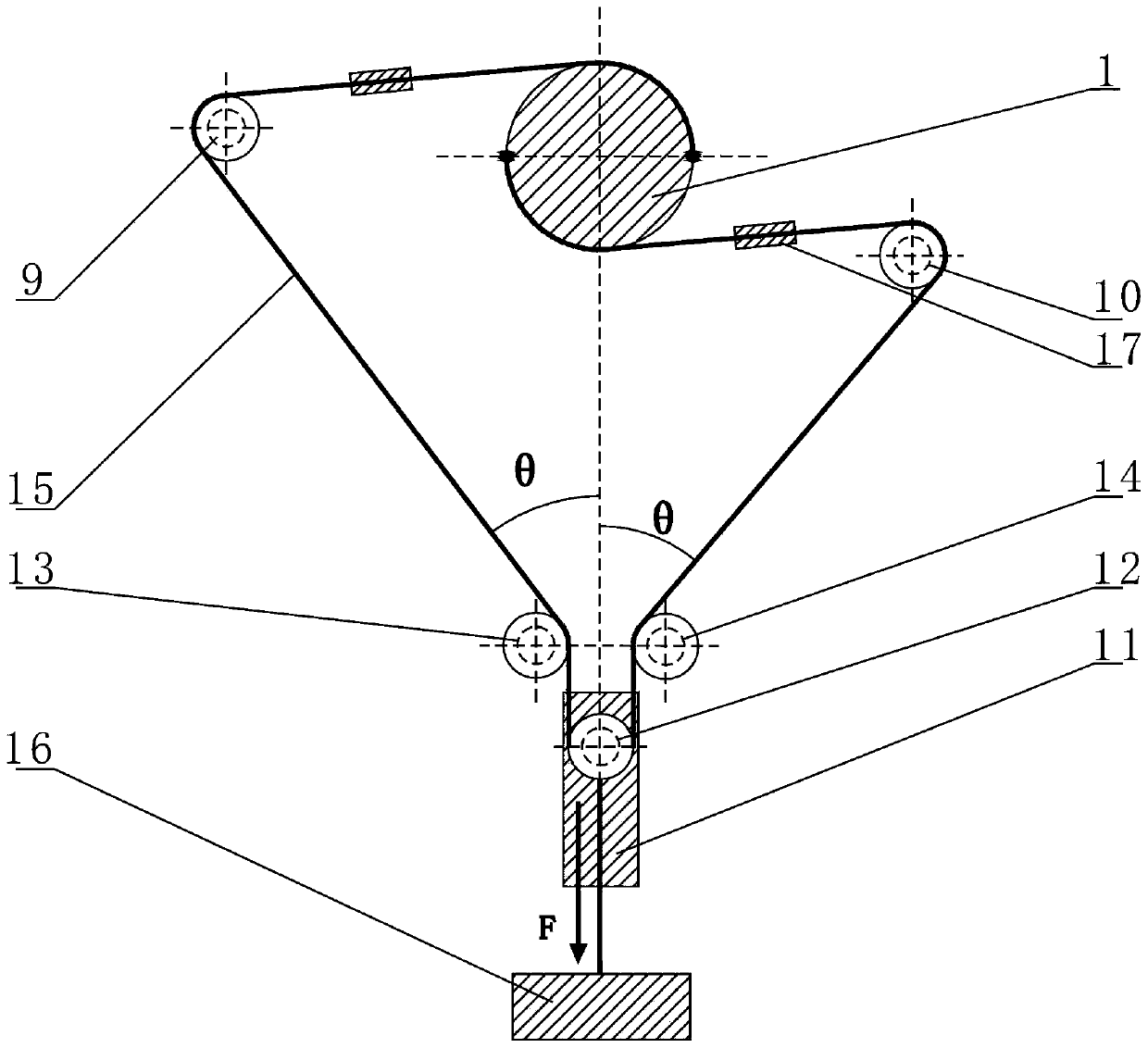

[0054] The following is based on Figure 1-6 Describe in detail the measuring device and testing method of a horizontal swivel spherical hinge interface friction resistance in the embodiment of the present invention.

[0055] On the one hand, if Figure 1-5 As shown, the embodiment of the present invention discloses a device for measuring the interface friction of a horizontal swivel spherical hinge, including: a spherical hinge structure, a load system, and a traction system.

[0056] specific,

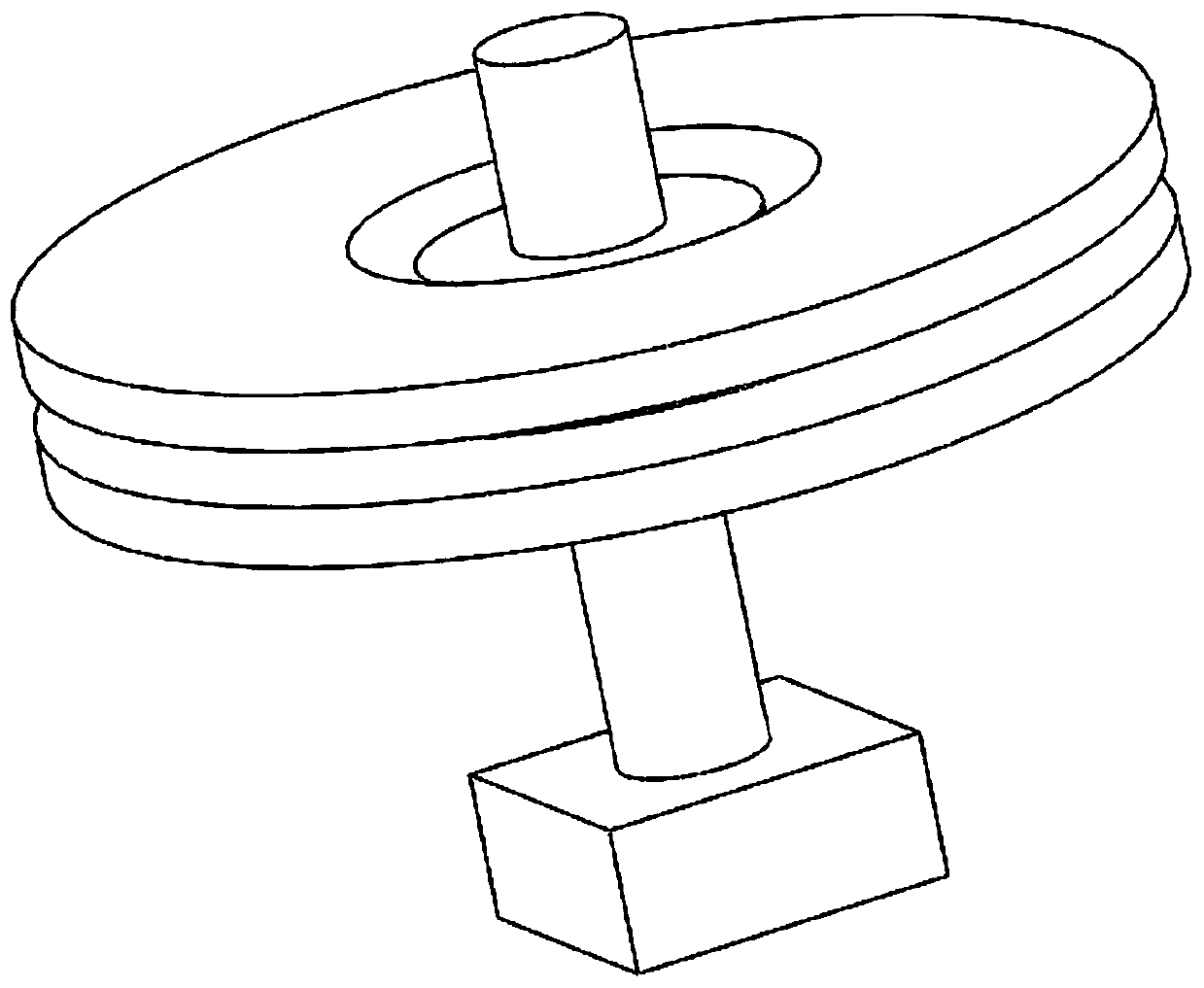

[0057] The ball joint structure includes an upper ball joint structure 1, a lower ball joint structure 2, and a positioning pin 3 installed at the center of the upper ball joint structure 1 and the lower ball joint structure 2; the upper ball joint structure 1 and the lower ball joint structure 2 can be relatively Locating pin shaft 3 rotates.

[0058] Installing the positioning pin shaft 3 at the center of the upper and lower ball joint structures 2 is to prevent the device from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com