Brake sticking mechanism for detachable saddle of deep sea carrying platform

A carrier platform and saddle technology, which is applied to motor vehicles, connecting components, mechanical equipment, etc., can solve the adverse effects of underwater operations, saddle loosening and other problems, meet the requirements of rapidity, prevent overload failure, and improve safety The effect of reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

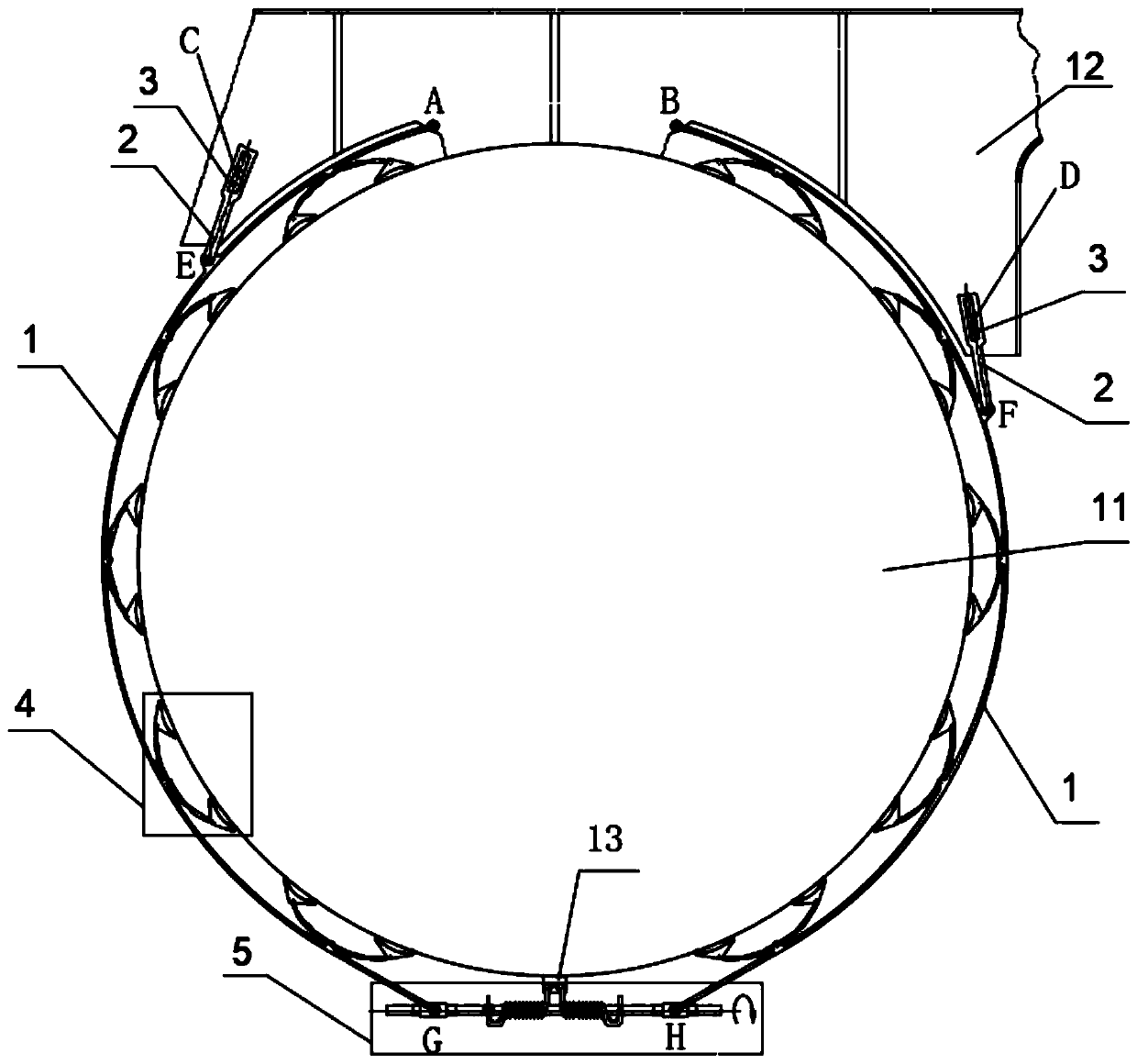

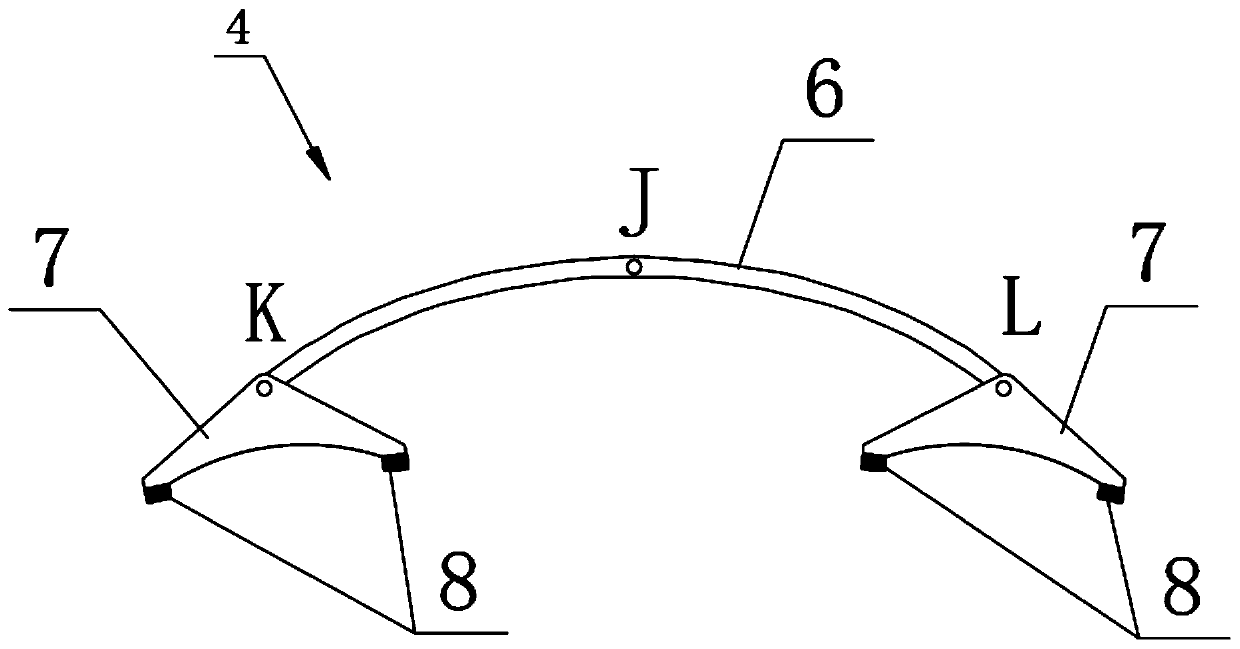

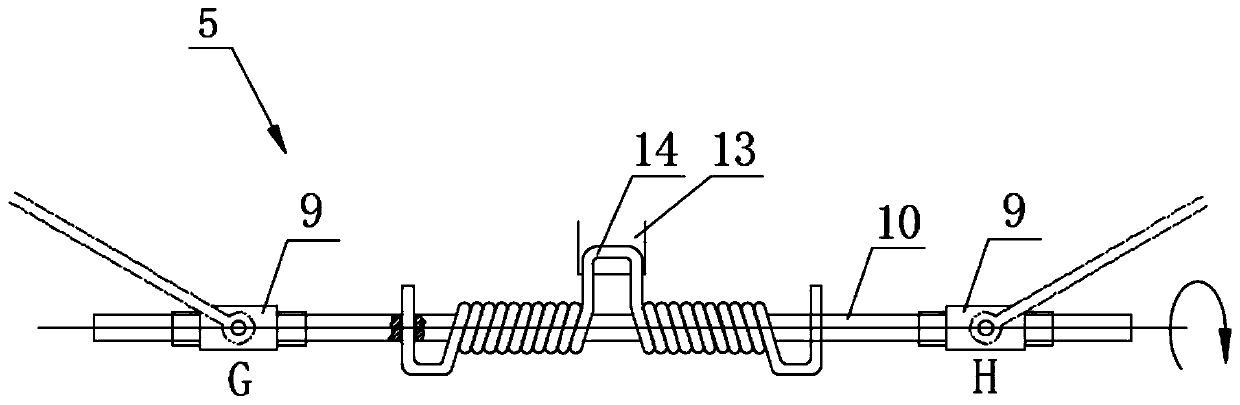

[0025] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

[0026] Such as figure 1 , figure 2 and image 3 As shown, the brake mechanism for the detachable saddle of the deep-sea carrier platform in this embodiment includes a saddle 12, and the bottom of the saddle 12 is provided with a pressure-resistant shell 11, and the two sides of the outer circumference of the pressure-resistant shell 11 are The strips 1 are symmetrically arranged, the tops of the two strips 1 are respectively hinged on the saddle 12, the bottoms of the two strips 1 are connected by an elastic connection assembly 5, and a stopper is provided at the middle of the bottom of the pressure-resistant shell 11 13, the elastic connection assembly 5 is connected to the block 13;

[0027] The two ends of the saddle 12 are respectively hinged with guide blocks 3, and the outer side of the upper part of the strip 1 is hinged with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com