Steel structure beam

A technology of steel structure beams and steel beams, applied in truss structures, joists, girders, etc., can solve problems such as insufficient stability, and achieve the effects of increasing stability performance, increasing bearing capacity, and increasing elastic loads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The standard parts used in the present invention can be purchased from the market, and the special-shaped parts can be customized according to the instructions and the records of the accompanying drawings. Conventional means such as welding and clasp fastening will not be described in detail here.

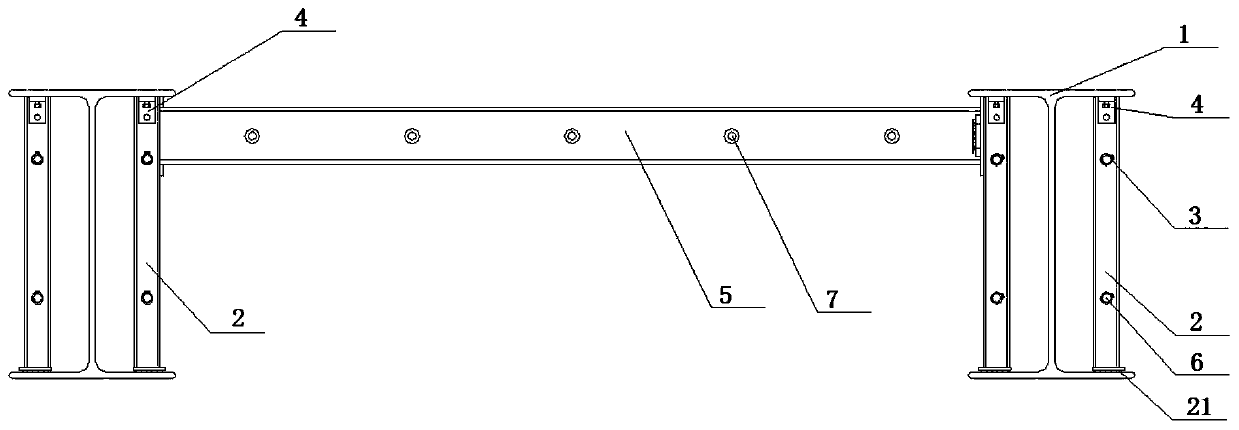

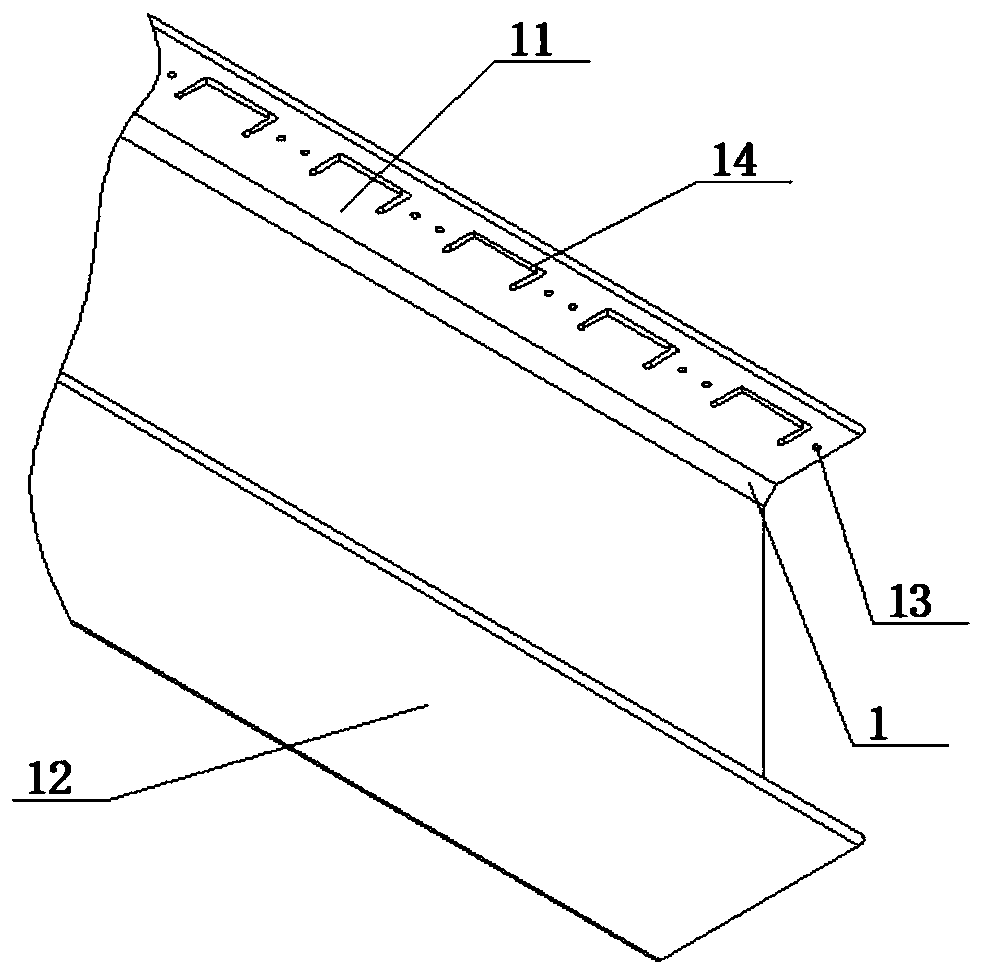

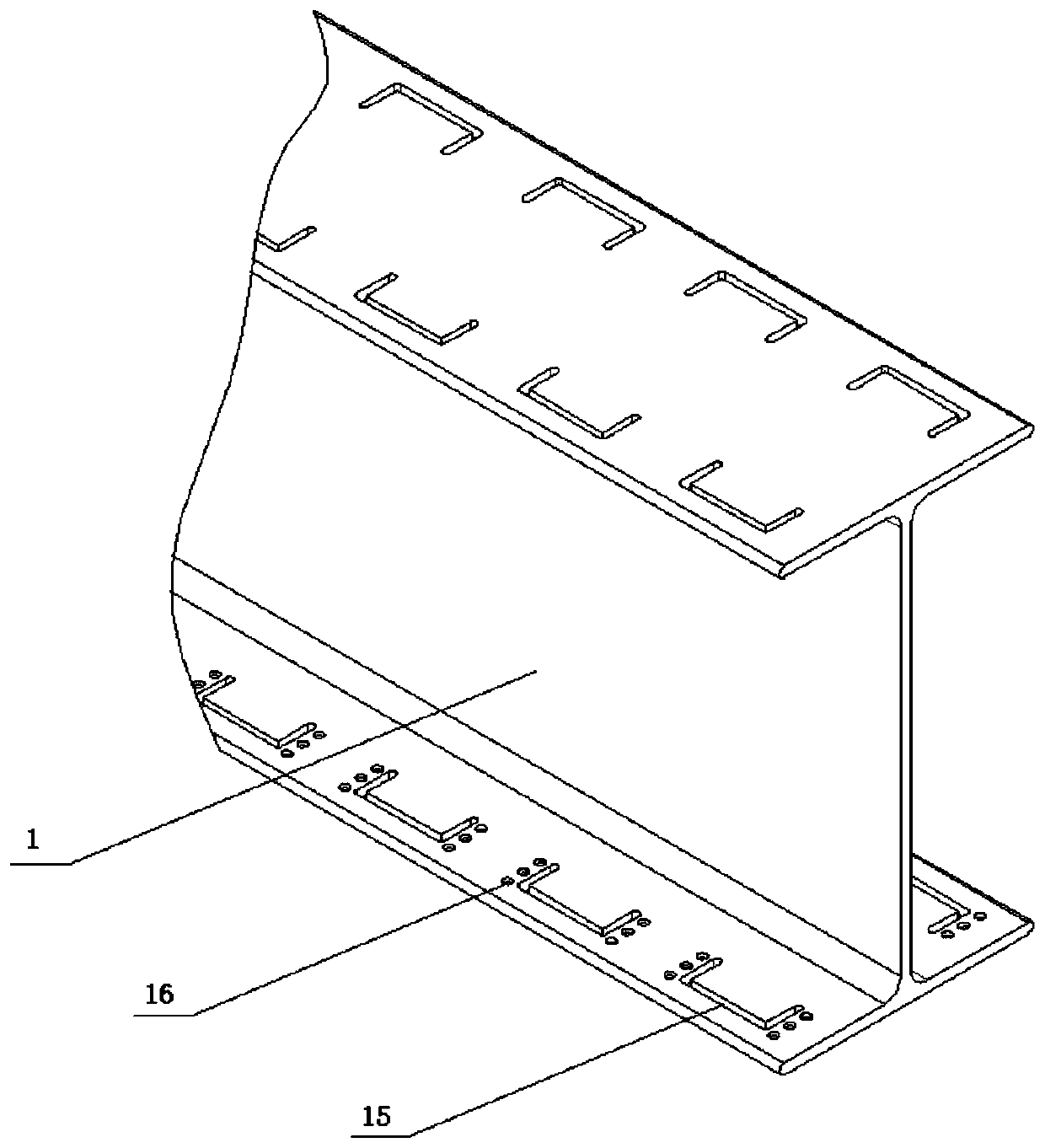

[0027] refer to Figure 1-12, a specific embodiment of the present invention comprises steel beam 1, and described steel beam 1 comprises upper plate 11, and several first through grooves 14 are uniformly arranged on upper plate 11, and channel steel 2 is connected in the first through groove 14, and groove The steel 2 is provided with a second through groove 24 near the end of the upper plate 11. The second through groove 24 is nested and connected to the rafters 5. The rafters 5 are linearly and uniformly distributed along the length direction of the steel beam 1. The top of the rafter 5 is inserted into the adjacent steel beam 1. In the second through groove 24 on the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com