Phosphogypsum ceramsite ball and spherical and gravel type phosphogypsum ceramsite ball light aggregate water stable layer

A technology of phosphogypsum and ceramsite, which is applied in the field of spherical and crushed phosphogypsum ceramsite balls with light aggregate water stabilization layer and phosphogypsum ceramsite balls, can solve the problems of reducing the strength of water stabilization layer, etc. Strength boosting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

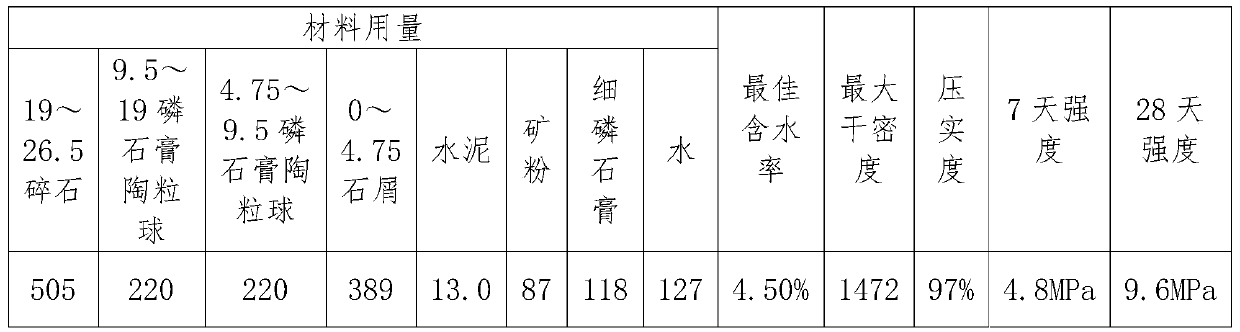

Embodiment 1

[0020] The embodiment of the present invention proposes a phosphogypsum ceramsite ball, which includes a phosphogypsum core, a persulfur phosphogypsum layer wrapped outside the phosphogypsum core, and a cement layer wrapped outside the persulfur phosphogypsum layer; wherein , The phosphogypsum core includes 88% original phosphogypsum, 0.26% calcium oxide, 4% cement clinker, 7.24% mineral powder and 0.5% electric pole residual slurry, which is granulated, and phosphorus is added during granulation The total weight of the gypsum core is 15% water; the layer of persulfate gypsum consists of 46% fine phosphogypsum, 49% slag and 5% cement clinker after mixing.

[0021] Preferably, the phosphogypsum core is mixed with the mixed persulfophosphogypsum layer components 14 hours after granulation, and wrapped to form the persulfophosphogypsum layer.

[0022] Preferably, cement powder is mixed in 20 hours after wrapping to form the persulfophosphogypsum layer, and wrap to form the cement...

Embodiment 2

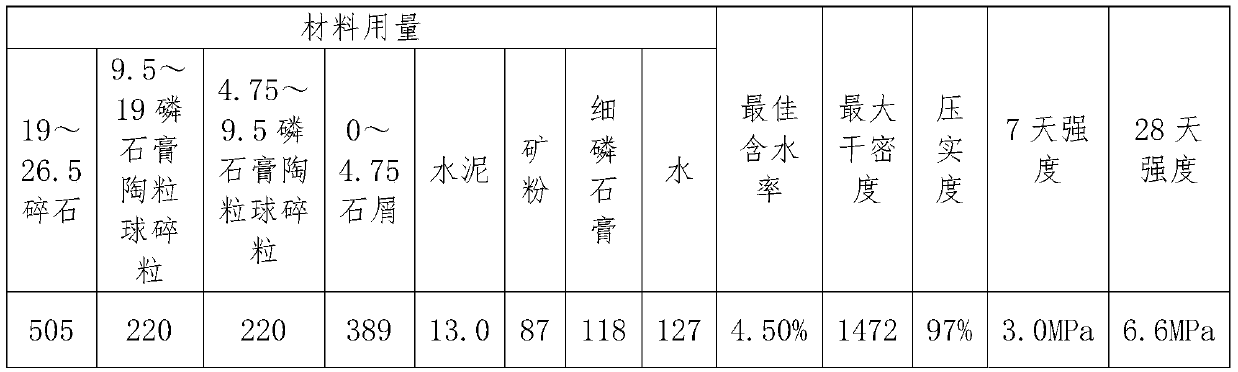

[0026] The embodiment of the present invention proposes a phosphogypsum ceramsite ball, which includes a phosphogypsum core, a persulfur phosphogypsum layer wrapped outside the phosphogypsum core, and a cement layer wrapped outside the persulfur phosphogypsum layer; wherein , The phosphogypsum core includes 88% original phosphogypsum, 0.26% calcium oxide, 4% cement clinker, 5.74% mineral powder and 2% electric pole residual slurry, which are granulated, and phosphorus is also added during granulation The weight of the gypsum core is 16.5% water; the layer of persulfate gypsum consists of 45% fine phosphogypsum, 50% slag and 5% cement clinker after mixing.

[0027] Preferably, the phosphogypsum core is mixed with the mixed persulfophosphogypsum layer components 16 hours after granulation, and wrapped to form the persulfophosphogypsum layer.

[0028] Preferably, cement powder is mixed in 24 hours after wrapping to form the persulfophosphogypsum layer, and wrap to form the cement...

Embodiment 3

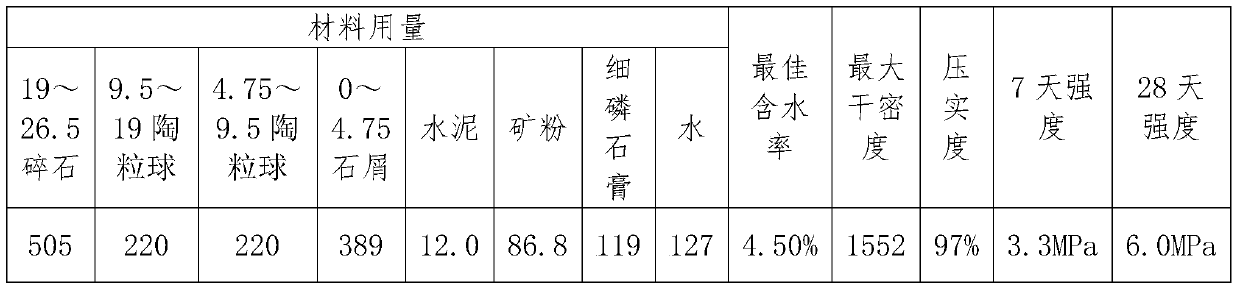

[0032] The embodiment of the present invention proposes a phosphogypsum ceramsite ball, which includes a phosphogypsum core, a persulfur phosphogypsum layer wrapped outside the phosphogypsum core, and a cement layer wrapped outside the persulfur phosphogypsum layer; wherein , The phosphogypsum core includes 88% original phosphogypsum, 0.26% calcium oxide, 4% cement clinker, 4.74% mineral powder and 3% electric pole residual slurry, which are granulated, and phosphorus is also added during granulation The weight of the gypsum core is 18% water; the layer of persulfate gypsum consists of 50% fine phosphogypsum, 45% slag and 5% cement clinker after mixing.

[0033] Preferably, the phosphogypsum core is mixed with the mixed persulfophosphogypsum layer components 18 hours after granulation, and wrapped to form the persulfophosphogypsum layer.

[0034] Preferably, cement powder is mixed in 28 hours after wrapping to form the persulfophosphogypsum layer, and wrap to form the cement l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com